A two-speed high-voltage explosion-proof three-phase asynchronous motor with non-double pole design

A three-phase asynchronous, explosion-proof technology, applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of high temperature rise of rotating motors, insufficient stirring speed, low starting performance, etc., to avoid the harmonic magnetic field of the motor , to meet the needs of normal production, to ensure the effect of mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

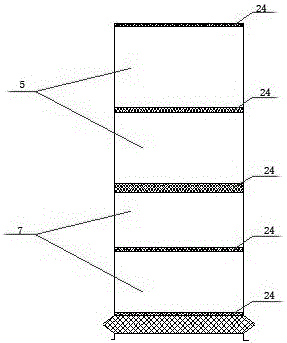

[0021] Such as Figure 5 As shown, a double-speed high-voltage explosion-proof three-phase asynchronous motor adopts non-double pole design, which consists of stator 3, rotor 4, bearing device 1, end cover 9, and end cover 8. The rotor 4 is placed in the front and rear two bearing devices 1, the bearing device 1 is connected with the front and rear end covers 9 by bolts respectively, the front and rear end covers 9 are connected with the stator 3 by bolts, the end cover 8 and the end cover 9 are connected by bolts, the end cover 9, the outer fan 11, The stator 3 forms an open-loop external air path; the rotor 4 is composed of a rotor iron core, a squirrel cage, a shaft, a key, an inner fan 10, an air guide tube 13, and a balance ring, the squirrel cage is placed on the rotor iron core, and the rotor iron The core and the shaft adopt an interference fit and are connected by a key. The air guide tube 13, the balance ring, and the inner fan 10 all adopt an interference fit with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com