New method for manufacturing interconnected copper pillars among plurality of layers of circuit boards

A technology of multi-layer circuit and new method, applied in the direction of multi-layer circuit manufacturing and the formation of electrical connection of printed components, etc., can solve the problems of circuit board stability and reliability effects, save plating time, stable and reliable performance, and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0037] A new method for manufacturing interconnected copper pillars between layers of a multilayer circuit board, comprising the following steps:

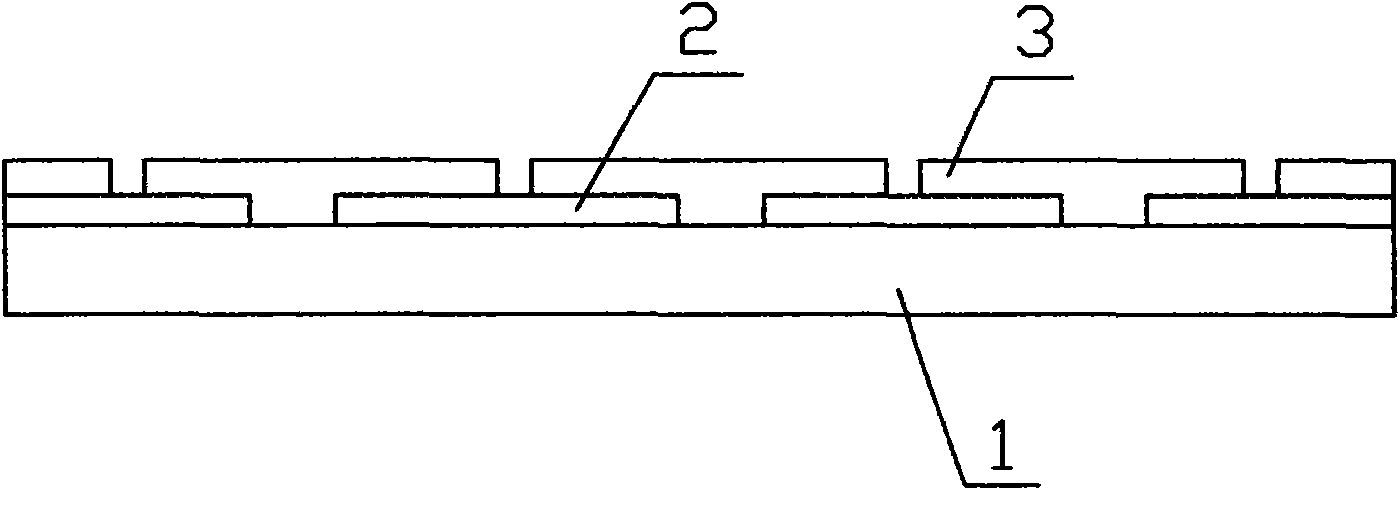

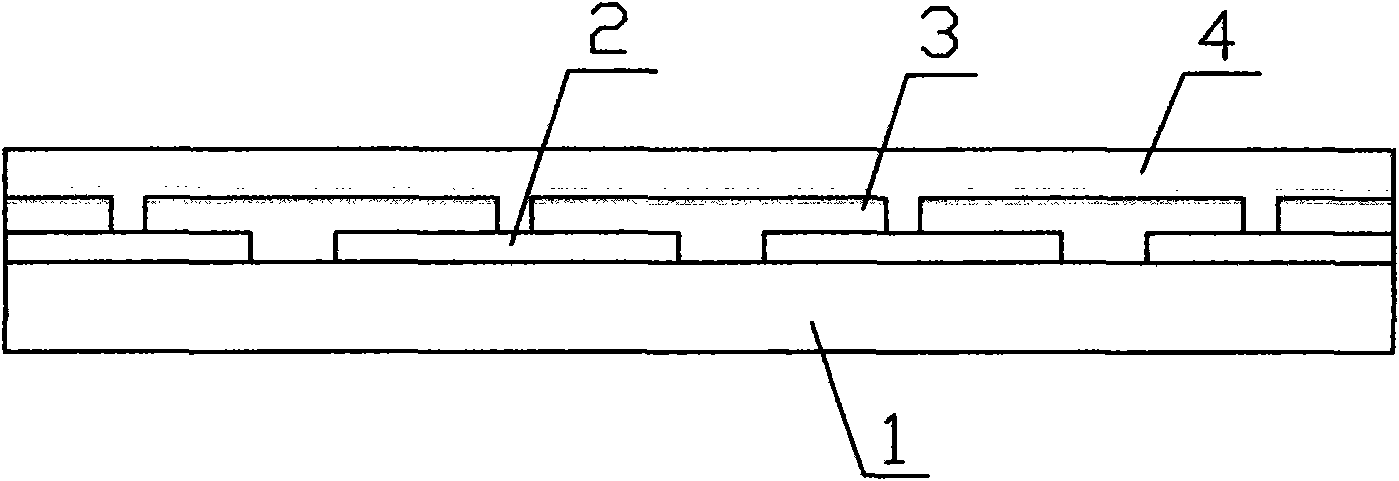

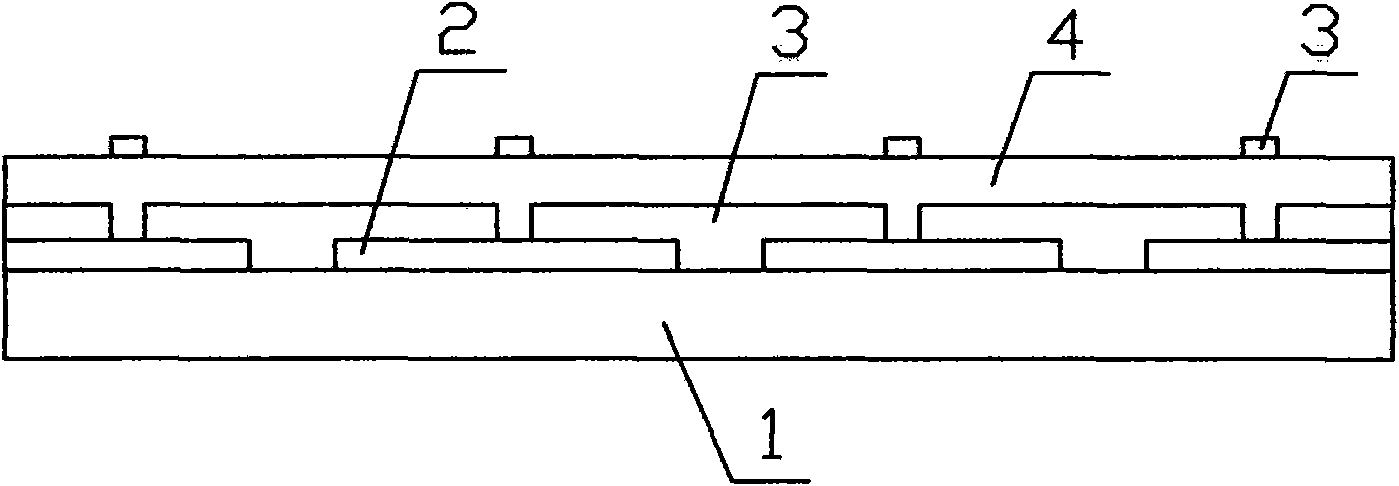

[0038] Step 1: If figure 1 As shown, a layer of permanent photosensitive layer 3 is coated or laminated on the copper foil 2 of the inner circuit board 1 , and the permanent photosensitive layer 3 is exposed to the position where the copper column needs to be electroplated after being exposed to light and developed.

[0039] Wherein the permanent photosensitive layer 3 can be dissolved or insoluble before the photosensitive reaction occurs, and after partial exposure, a local photosensitive reaction is triggered, and the part where the photosensitive reaction occurs cannot be dissolved or can be dissolved in water, alkaline water or an organic solvent. After the undissolved part of the permanent photosen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com