Electrocoppering plating solution and electrocoppering method

A technology of electroplating copper and plating solution, which is applied in the field of electroplating copper plating solution and electroplating copper, which can solve the problems that the copper plating layer affects the application of electroplating copper, the research on the surface performance of the copper plating layer, and the poor surface performance of the plating layer, etc., so as to shorten the electroplating time , The copper plating layer is bright and smooth, and the effect of improving the surface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

[0053] (1) Test method 1: On the copper-plated workpiece, use the tip of a knife to draw parallel or staggered scratches that reach the base (forming a 1mm×1mm square), and then paste it with 3M adhesive tape and tear it off. The coating will not be damaged. Bubble shedding is qualified;

test approach 2

[0054] (2) Test method 2: use a file to file the edge of the plated piece, if the edge of the plated piece does not bubble or only 1mm on the edge when filing 2 Peeling within the range is qualified;

test approach 3

[0055] (3) Test method 3: keep the plated parts at 260°C for 1 hour, take them out and quench them in cold water, and repeat 10 times if no peeling and peeling of the plating layer is found, it is qualified.

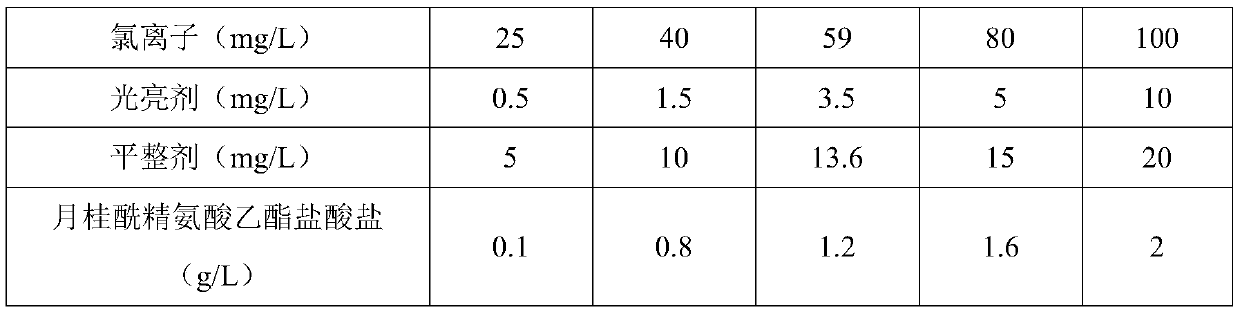

[0056] The experimental results are shown in Table 2.

[0057] Table 2 Copper coating adhesion test results

[0058]

[0059]

[0060] As can be seen from Table 2, the copper plating layer formed on the workpiece surface by the electroplating copper plating solution provided by the present invention has good adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com