Nickel-plated steel strip, steel battery case manufactured from the steel strip, and method of manufacturing the steel battery case

A battery steel shell and steel strip technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of affecting battery storage life, rusting on the outer surface of the battery, and increasing the porosity of the coating, so as to avoid battery leakage. problem, improve the leakage problem, improve the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

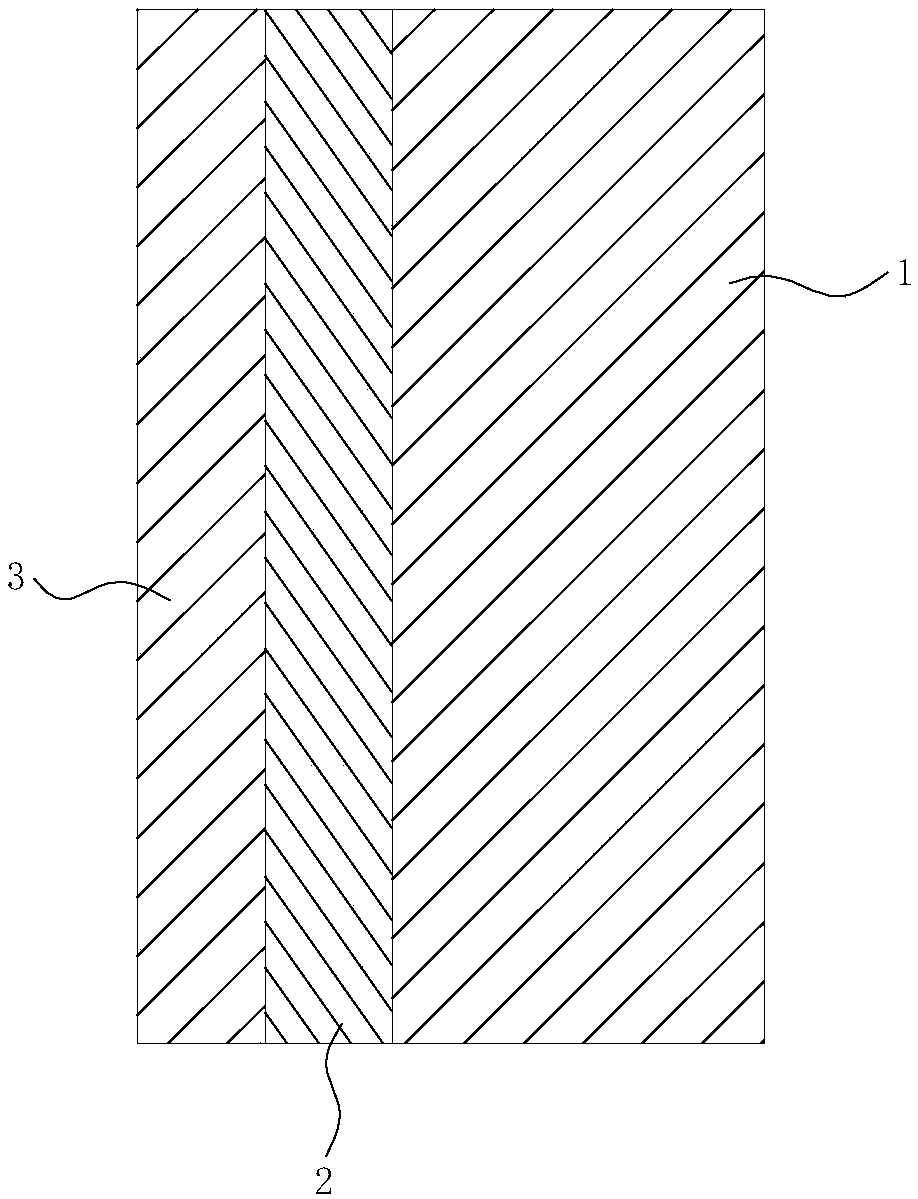

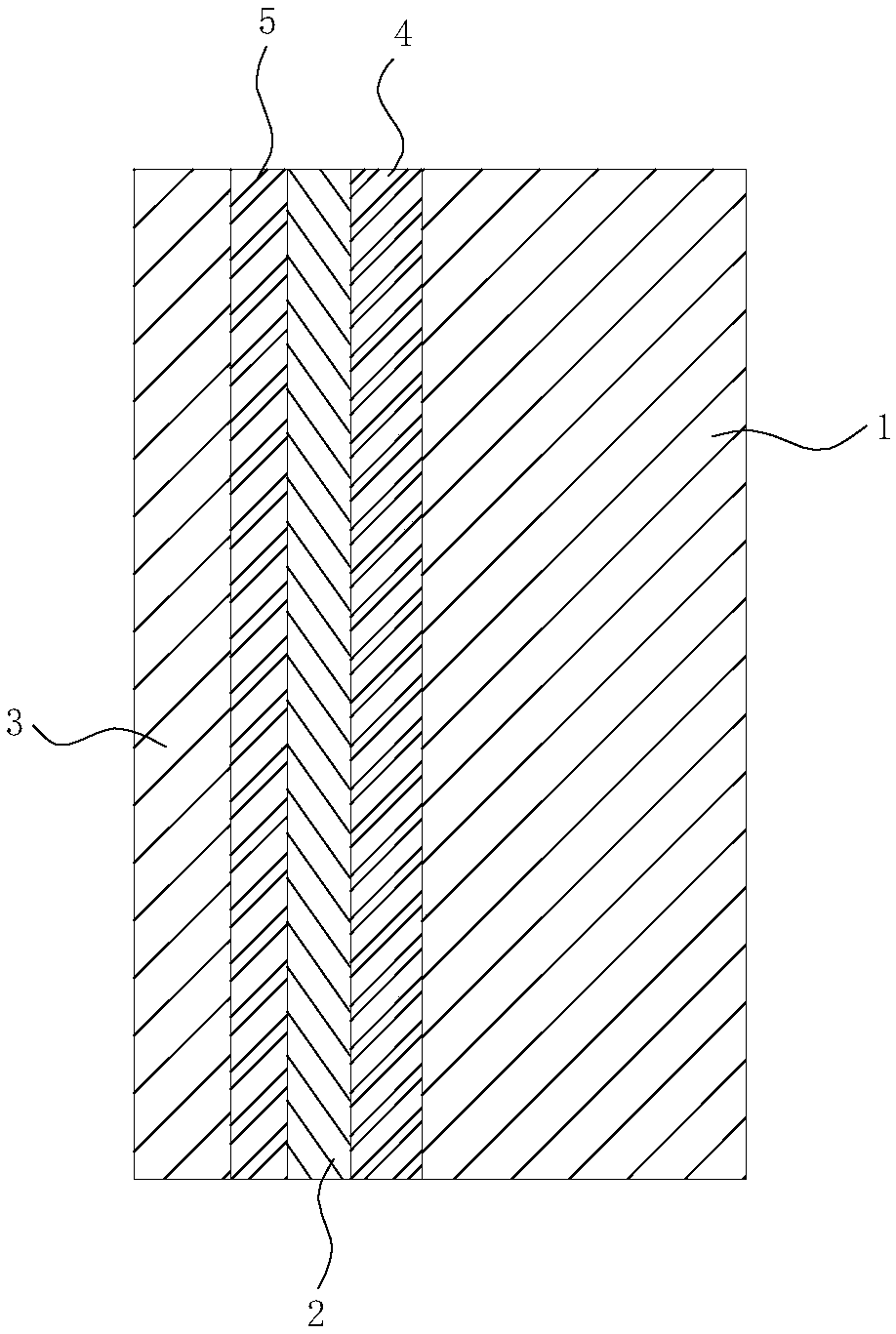

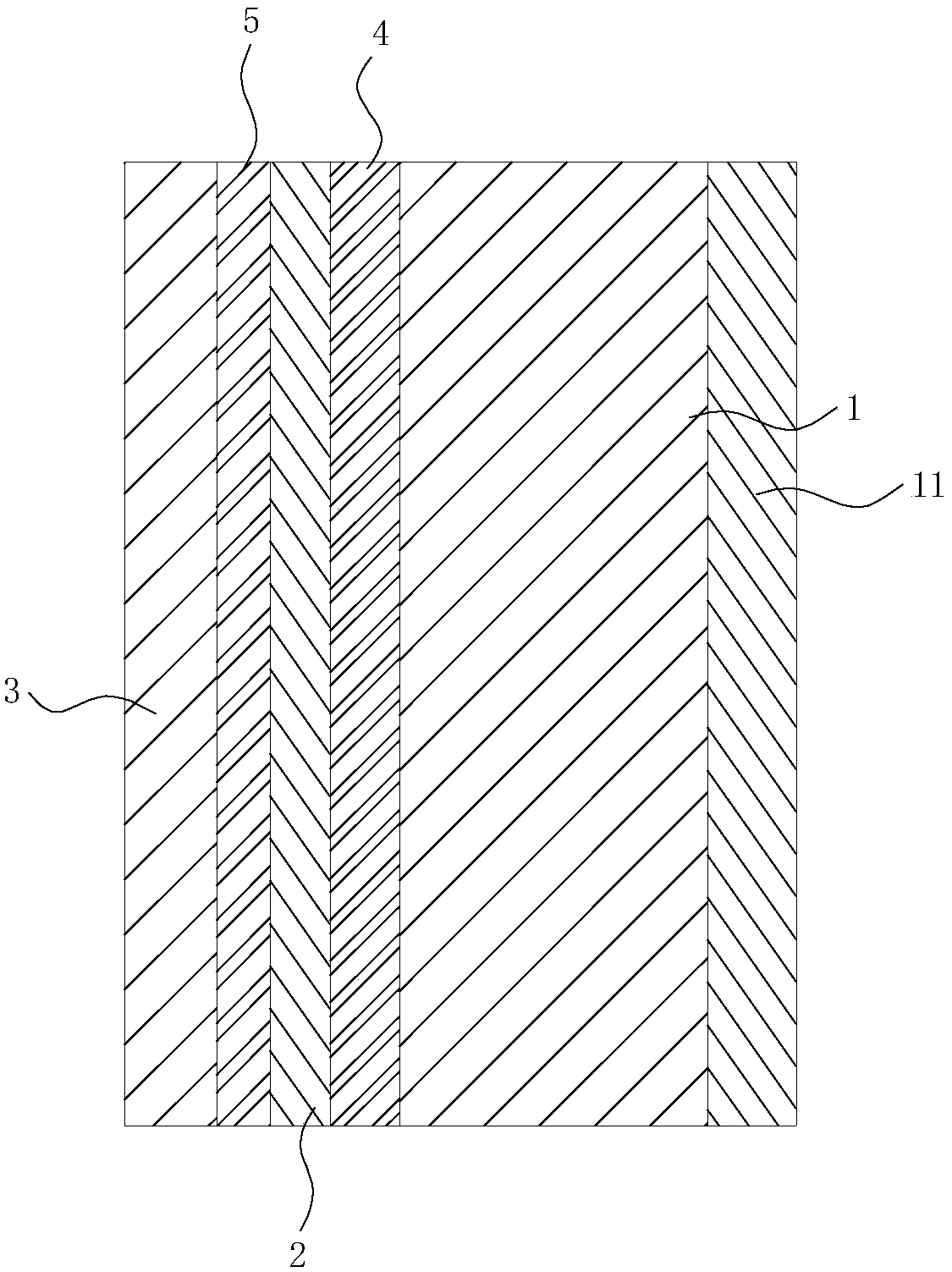

[0061] Such as figure 1 , 2 As shown, the Ni-coated steel strip in this embodiment includes an Fe substrate 1 , the inner surface of the Fe substrate 1 has a Ni coating 2 , and the surface of the Ni coating 2 has an Fe coating 3 . Under the effect of heat treatment, the part of the Ni coating 2 close to the Fe matrix 1 interpenetrates and alloys with the Fe matrix 1 to form the bottom Fe-Ni alloy layer 4, and the Fe coating 3 and the Ni coating 2 interpenetrate and alloy to form the surface Fe-Ni alloy Layer 5, a part of Ni plating layer 2 remains between the surface Fe-Ni alloy layer 5 and the bottom Fe-Ni alloy layer 4.

[0062] In the present embodiment, the surface of the Fe substrate and the Ni coating are not interpenetrated and alloyed, the thickness of the Ni coating 2 is 0.3 μm, the thickness of the Fe coating 3 on the surface of the Ni coating 2 is 0.015 μm, and the surface of the Fe substrate 1 and the Ni coating 2 In the state where the bottom Fe-Ni alloy layer 4...

Embodiment 2

[0074] Such as figure 1 , 2 As shown, the Ni-coated steel strip in this embodiment includes an Fe substrate 1 , the inner surface of the Fe substrate 1 has a Ni coating 2 , and the surface of the Ni coating 2 has an Fe coating 3 . Under the effect of heat treatment, the part of the Ni coating 2 close to the Fe matrix 1 interpenetrates and alloys with the Fe matrix 1 to form the bottom Fe-Ni alloy layer 4, and the Fe coating 3 and the Ni coating 2 interpenetrate and alloy to form the surface Fe-Ni alloy Layer 5, a part of Ni plating layer 2 remains between the surface Fe-Ni alloy layer 5 and the bottom Fe-Ni alloy layer 4.

[0075] In the present embodiment, the surface of the Fe substrate and the Ni coating are not interpenetrated and alloyed, the thickness of the Ni coating 2 is 1.0 μm, the thickness of the Fe coating 3 on the surface of the Ni coating 2 is 0.02 μm, and the surface of the Fe substrate 1 and the Ni coating 2 In the state where the bottom Fe-Ni alloy layer 4 ...

Embodiment 3

[0087] Such as figure 1 , 2 As shown, the Ni-coated steel strip in this embodiment includes an Fe substrate 1 , the inner surface of the Fe substrate 1 has a Ni coating 2 , and the surface of the Ni coating 2 has an Fe coating 3 . Under the effect of heat treatment, the part of the Ni coating 2 close to the Fe matrix 1 interpenetrates and alloys with the Fe matrix 1 to form the bottom Fe-Ni alloy layer 4, and the Fe coating 3 and the Ni coating 2 interpenetrate and alloy to form the surface Fe-Ni alloy Layer 5, a part of Ni plating layer 2 remains between the surface Fe-Ni alloy layer 5 and the bottom Fe-Ni alloy layer 4.

[0088] In this embodiment, when the surface of the Fe substrate is not interpenetrated and alloyed with the Ni coating, the thickness of the Ni coating 2 is 0.7 μm, and the surface of the Fe substrate 1 and the Ni coating 2 are interpenetrated and alloyed to form the bottom Fe-Ni alloy layer 4. , the thickness of the underlying Fe-Ni alloy layer 4 is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com