A method for manufacturing transparent electric heating glass with high light transmittance and low square resistance

An electric heating glass, high light transmittance technology, applied in transparent/reflective heating devices, printed circuit manufacturing, copying/marking methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

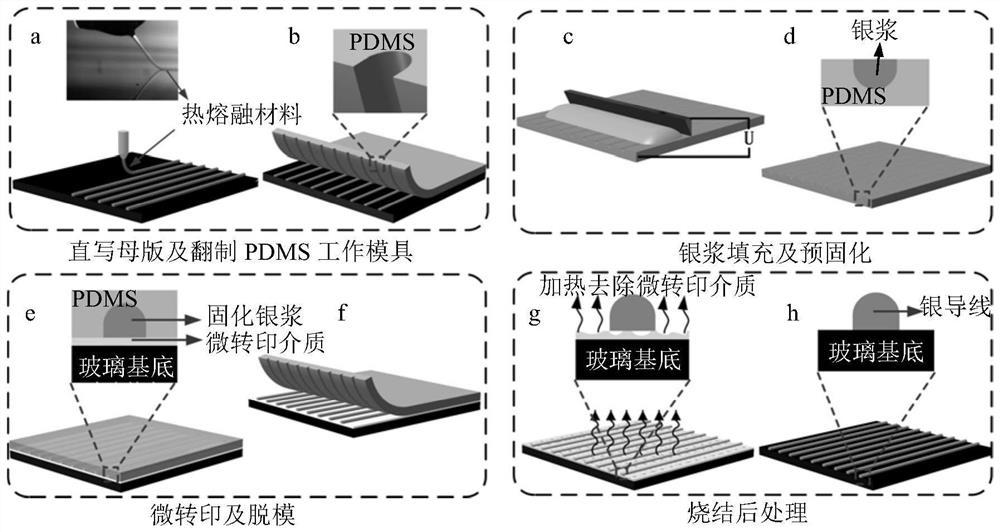

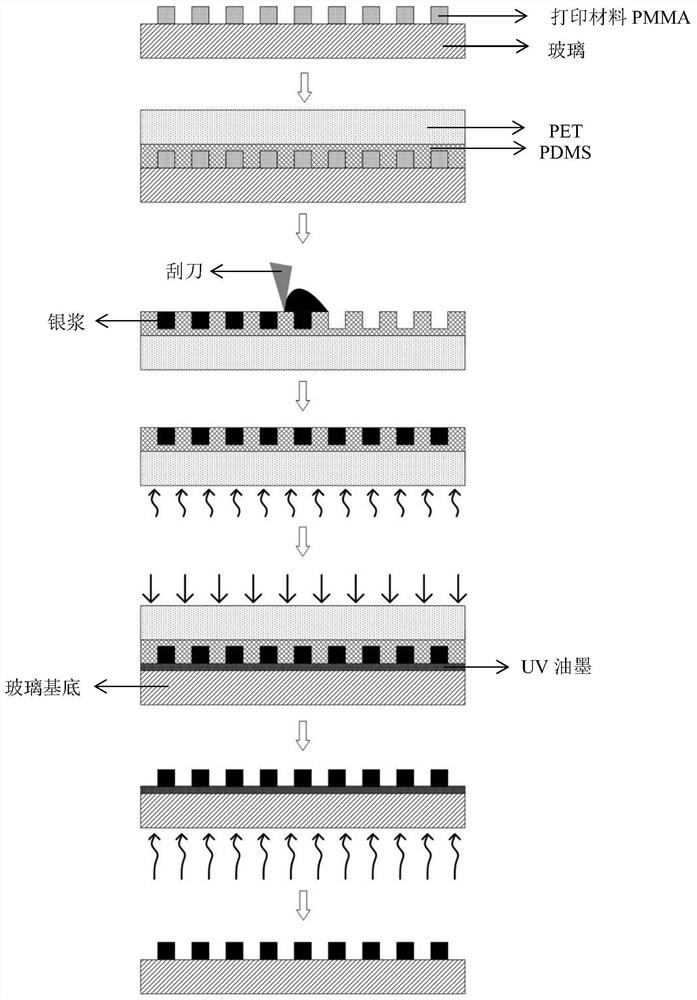

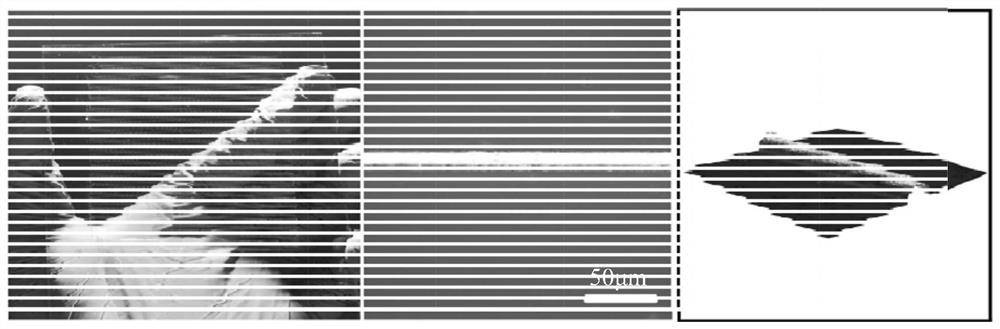

[0071] In this embodiment, a large-area master mold structure is manufactured by electric field-driven fused deposition direct writing technology, and then the master mold structure is transferred to the PDMS working mold through a graphic replication process, and then the PDMS working mold is filled with high-temperature sintered silver paste, and finally the PDMS working mold is filled with UV-assisted microtransfer transfers the conductive structure to the target substrate (glass), and the fabricated pattern structure is a wire grid structure. manufacturing process such as figure 2 As shown, the specific preparation steps include:

[0072] (1) Manufacture of the master mold: a large-size master mold (master plate) is manufactured using the electric field-driven fused deposition direct writing technology.

[0073] Ordinary glass is used as the substrate (substrate). Firstly, the glass substrate was cleaned, deionized water was ultrasonically treated for 10 minutes, and th...

Embodiment 2

[0090] In this embodiment, a large-area master mold structure is manufactured by electric field-driven fused deposition direct writing technology, and then the master mold structure is transferred to PDMS through a pattern replication process, and then the PDMS working mold is filled with high-temperature sintered silver paste, and finally UV-assisted Micro-transfer printing transfers the silver wires to the target substrate (glass), and the fabricated conductive structure is a grid structure. manufacturing process such as figure 2 As shown, the specific preparation steps include:

[0091] (1) Manufacture of the master mold: a large-size master mold (master plate) is manufactured using the electric field-driven fused deposition direct writing technology.

[0092] Ordinary glass is used as the substrate (substrate). Firstly, the glass substrate was cleaned, ultrasonically treated with deionized water for 10 min, and then blown dry with nitrogen. Using PMMA as the printing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com