Process for forming pipe end sleeves

A forming process and parts technology, which is applied in the field of forming process of pipe end sleeve parts, can solve the problems of non-sticking tires, increased forming work, and the inability of manual forming to ensure that parts fully meet the requirements of drawings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

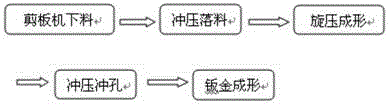

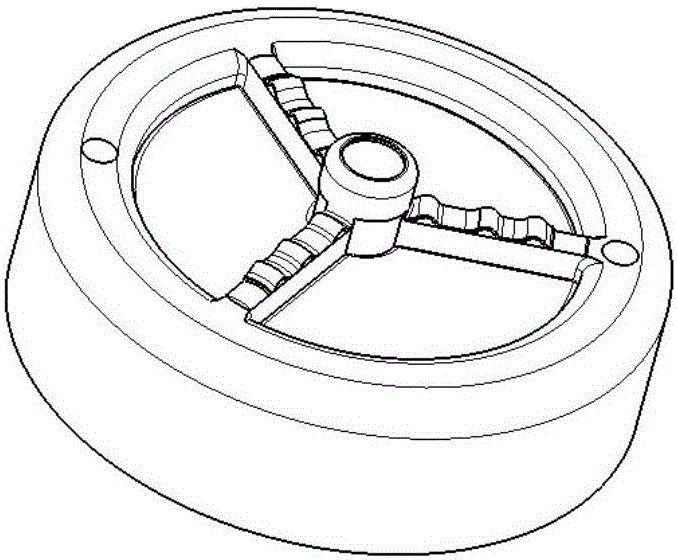

[0020] to attach figure 1 Take the part shown as an example to explain the forming process of the part in detail:

[0021] (1) The shearing machine is used for cutting the material, and the rectangular wool is cut by the shearing machine.

[0022] (2) Stamping and blanking, firstly, the workers use the punch 63T to drop the circular unfolded material to prepare for spinning.

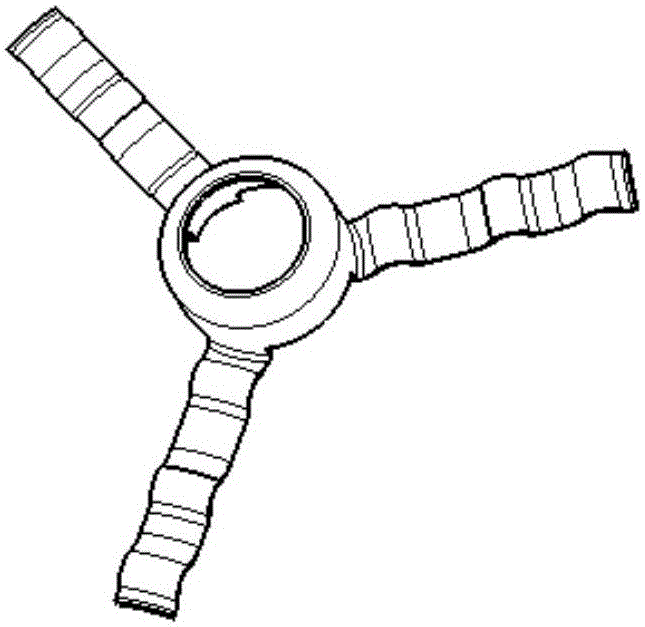

[0023] (3) Spinning forming, sheet metal operators use spinning tires to form parts, the effect is as follows Figure three .

[0024] (4) Stamping and punching, first the worker drills the tool hole, and then uses the punching machine to punch the hole.

[0025] (5) Sheet metal forming. First, workers use the mold to cut and shape. The cutting and forming mold only has the cutting function. When cutting, put the spinning-formed hat on the lower mold, and then use this set of molds to cut. This process scheme can effectively avoid the occurrence of stress concentration when forming small flanges.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com