A kind of high-performance metal grid transparent electrode manufacturing method and its obtained transparent electrode and application

A metal grid, transparent electrode technology, used in cable/conductor manufacturing, equipment for manufacturing conductive/semiconducting layers, final product manufacturing, etc., can solve the problem of low-cost manufacturing of rigid base metal grids, high viscosity Difficulty of paste printing, low resolution of inkjet printing, etc., to achieve the effect of enhancing jetting stability and deposition accuracy, high efficiency and low cost, large-scale manufacturing, and low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

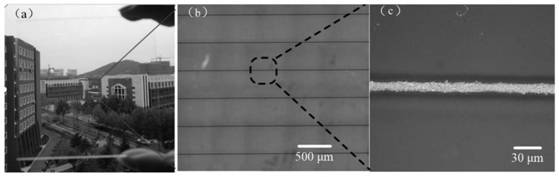

[0045] This embodiment is based on the embedded 3D printing technology of electric field-driven spray deposition liquid film, and selects high-temperature sintered silver paste to directly print a graphic structure with a large aspect ratio on the substrate spin-coated with liquid PDMS. The manufactured graphic structure is a line grid structure. Concrete preparation steps include:

[0046] (1) Substrate pretreatment

[0047] Ordinary glass is used as the substrate. First, ultrasonically treat the glass substrate with deionized water for 10 minutes, then dry it with nitrogen gas, and finally use a plasma processor to conduct plasma bombardment treatment on the glass surface to modify the surface of the substrate and improve the adhesion between the printing material and the substrate;

[0048] (2) Coating liquid PDMS material

[0049] Spread a layer of liquid PDMS polymer on the surface of the substrate, select an appropriate amount of Dow Corning 184 canned glue, mix the P...

Embodiment 2

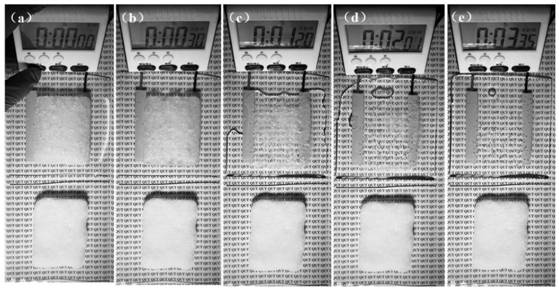

[0060] This embodiment is based on the electric field-driven jet deposition liquid film embedded 3D printing technology, selects high-temperature sintered silver paste (Shanghai Xinlui 8060 silver paste), and prints a large aspect ratio by directly printing on the substrate spin-coated with liquid PDMS. The conductive pattern of the structure, the pattern structure manufactured is a grid structure. Concrete preparation steps include:

[0061] (1) Pretreatment

[0062] Take ordinary glass as the substrate for 3D printing, first use acetone to ultrasonically clean it for 10 minutes, then use isopropanol to ultrasonically clean it for 10 minutes, then rinse it with deionized water, then dry it with nitrogen, and take it out for use;

[0063] (2) Coating liquid PDMS material

[0064] A layer of PDMS film with a thickness of about 10 microns is coated on the surface of the substrate by spin coating. The specific operation is as follows: select Sylgard 184 PDMS liquid from Dow Cor...

Embodiment 3

[0075] In this embodiment, a silicon wafer is used as the printing substrate, and the solar cell panel uses front silver conductive silver paste (DuPont MD2SP (PV20A)) as the metal paste for printing, and Sylgard 184PDMS liquid of Dow Corning Company is selected as the polymerizable material. This embodiment is applicable to the manufacture of the front wire grid electrode of the solar cell panel.

[0076] Step 1: Substrate Pretreatment

[0077] Using a silicon wafer as the printing substrate, it was first ultrasonically cleaned with acetone for 10 min, then with isopropanol for 10 min, then rinsed with deionized water, and then dried with nitrogen.

[0078] Step 2: Spin-coat a layer of liquid PDMS on the silicon substrate

[0079] Sylgard 184PDMS liquid from Dow Corning Company was selected as the spin-coating material. After the PDMS monomer and its corresponding curing agent were mixed uniformly at a ratio of 10:1, they were fully stirred and placed in a vacuum drying oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com