Composite profile control system and construction method for plugging by using composite profile control system

A construction method and system technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problems of profile control effect and economic benefit deterioration, single profile control agent construction method, etc., to achieve extended profile control Effects of cutting validity period, improving particle injection and injection depth, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Example 1 Typical block: Wangyao area of Changqing Oilfield, which belongs to heterogeneous low-permeability fractured reservoir.

[0084] From March to November 2013, a total of 7 wells were profile-modified in Wangyao District, corresponding to the cumulative increase of 1578.93 tons of horizontal wells, the cumulative precipitation of 2852.12 m3, the comprehensive water cut decreased by 15.9 percentage points, and the average oil increase of a single well group was 225 tons.

[0085] Figure 10 It is a comparison chart of the production situation before and after the measures in Wangyao District.

Embodiment 2

[0086] Example 2 Well Wang 26-38 in Changqing Oilfield

[0087] Production status before the measures: The two horizontal wells corresponding to this well were put into production in 2012: Danping 7 was put into production in September, with a high water cut of nearly 100%, and Danping 9 was put into production in December, and the water cut was as high as 89.5%. Figure 11 Schematic diagram of profile control well location for Wang 26-38 well group.

[0088] The well was constructed from March 29 to June 6, 2013, and a total of 4620m of plugging agent was injected 3 , plugging agent dry material 77.694t, initial construction pressure 8.8MPa, maximum pressure 11.4MPa, completed the deep profile control construction design.

[0089] Figure 12 It is the construction curve diagram of Well Wang 26-38. Figure 13 It is the pressure drop curve before and after profile control of Well Wang 26-38.

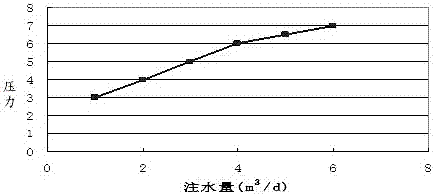

[0090] After the implementation of deep profile control, the water injection pres...

Embodiment 3

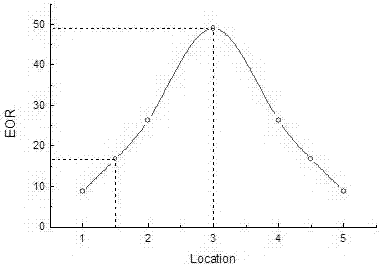

[0091] Example 3 Wells NP12-50 and NP12-X66 in Jidong Oilfield

[0092] Wells NP12-50 and NP12-X66 were simultaneously implemented composite deep profile control on 2016.9.1-11.24 and 2016.9.8-12.6 respectively, and the well group corresponds to five oil wells NP12-X71-46-48-49-X74, Figure 16 It is a schematic diagram of profile control well locations in NP12-50 and NP12-X66 well areas. Figure 17 It is the current water injection string and profile control string diagram of Well NP (Nanbao) 12-50.

[0093] Well NP12-50 started profile control on September 1, 2016, and it took 85 days to complete profile control on November 24, with a total consumption of 8022m 3 .

[0094] The construction operation is basically normal, and the pressure rise is also normal. The injection pressure and injection volume are basically consistent with the design. In order to achieve a better oil stimulation effect, a composite slug is added on the basis of the total injection volume reaching th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com