Patents

Literature

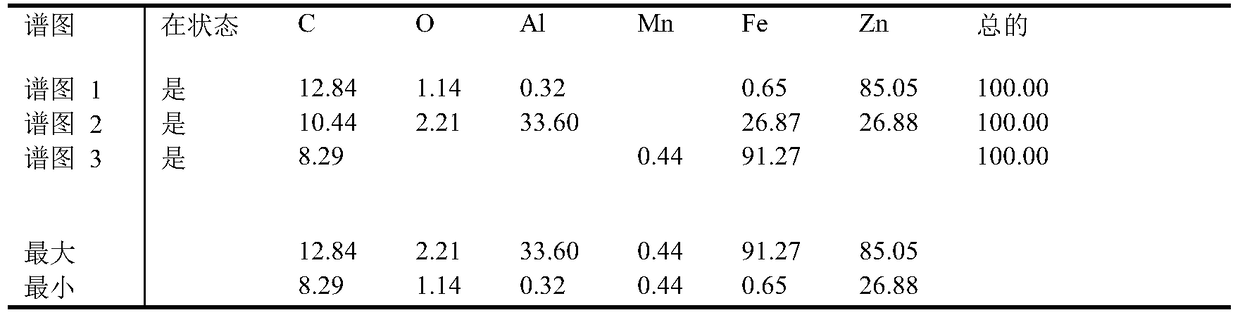

31results about How to "No missing plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

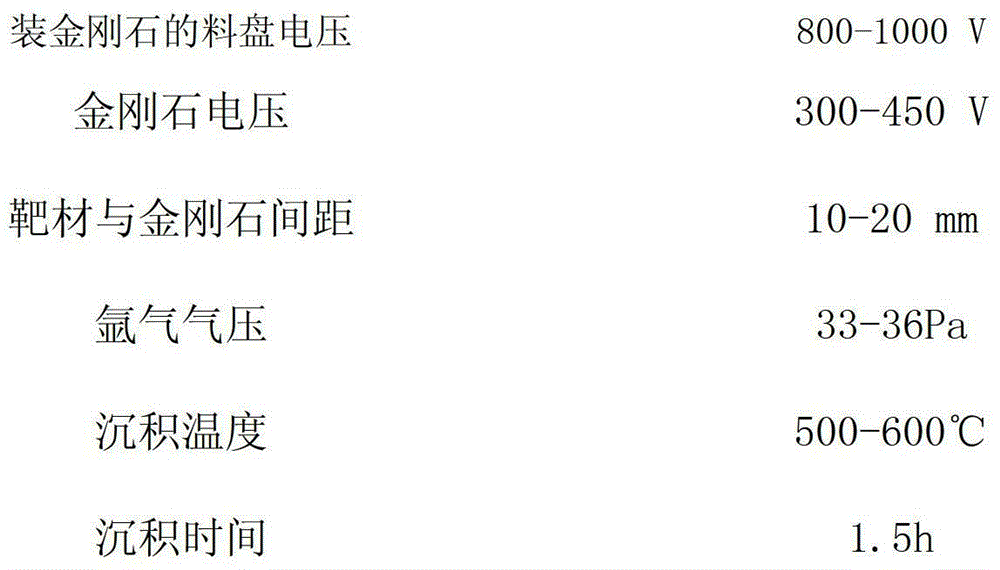

Plating assistant agent for zinc aluminum magnesium alloy hot dipping for steel wire

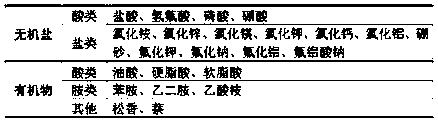

ActiveCN103510031AImprove bindingInhibit sheddingHot-dipping/immersion processesMg alloysActive agent

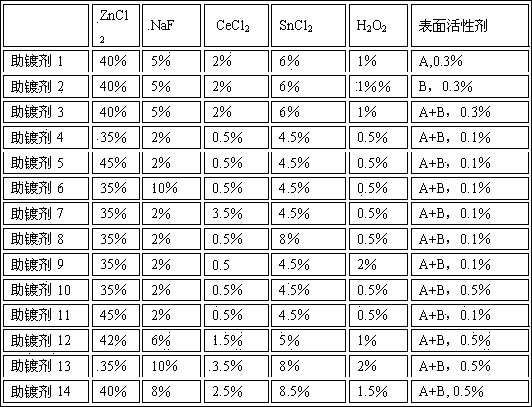

The invention relates to a plating assistant agent for zinc-aluminum-magnesium alloy hot dipping for a steel wire and belongs to the technical field of steel and iron material surface plating processes. The plating assistant agent is composed of 35-45 percent of ZnCl2, 2-10 percent of NaF2, 0.5-3.5 percent of CeCl2, 4.5-8.5 percent of SnCl2, 0.5-2 percent of H2O2, 0.1-05 percent of a surfactant and water in balancing amount. The surfactant is fatty alcohol ether sodium sulfate and / or sodium dodecyl sulfate. According to the invention, through a reasonable plating assistant agent formula, zinc-aluminum-magnesium alloy plating is obtained on the surface of the steel wire through hot dipping. The plating and the steel wire keep original performance respectively, more than 99.9 percent of a metallurgical bonding interface is obtained, the plating is compact in structure, plating leakage is avoided, and a zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance is formed. The corrosion resistance performance of the alloy plating is 2-4 times than that of normal hot-dipped pure zinc plating. The plating assistant agent is low in cost, can be used repeatedly and facilitates industrial production.

Owner:STATE GRID CORP OF CHINA +1

Coating thickness reduction ammonium salt-free plating auxiliary for hot galvanizing by solvent method

ActiveCN103938142AQuality improvementPrevent super thick phenomenonHot-dipping/immersion processesMetallurgyThin membrane

The invention relates to coating thickness reduction ammonium salt-free plating auxiliary for hot galvanizing by a solvent method. The plating auxiliary comprises the following components: 80-140g / L of ZnCl2, 5-60g / L of NaCl, 1-5g / L of MgCl2, 1-6g / L of KCl, 2-6g / L of oleic acid, 2-10g / L of NiCl2 and the balance of water. The plating auxiliary provided by the invention can solve the problem of pollution and super-thick coating during hot galvanizing by the solvent method. The plating auxiliary provided by the invention is simple in production process, and a uniform solvent film is formed on a pre-plating piece. During hot galvanizing, dense smoke and skip plating are avoided, the coating is bright in surface, the alloy layer in the zinc layer is thinned and the coating is thinned by over 50%, so that the zinc consumption and cost are reduced. The plating auxiliary provided by the invention is suitable for an ammonium salt-free plating assistant process for hot galvanizing by the solvent method with the thinned coating.

Owner:STATE GRID CORP OF CHINA +1

Hot galvanizing method

The invention provides a hot galvanizing method. The method comprises the following steps: washing ironware to be galvanized with acid, soaking the ironware in a plating assistant solvent for 5-10 minutes, taking out, and drying with hot air for 10-30 minutes under the condition of 80-100 DEG C; soaking in a hot galvanizing bath to contact the galvanizing solution, and controlling the temperature of the galvanizing solution at 460-480 DEG C; after 1-5 minutes, taking the ironware out of the galvanizing solution, and quickly cooling with air flow at 20-30 DEG C; and transferring the ironware out of the galvanizing region to obtain the galvanized ironware. The ironware made by the galvanizing method has the advantages of compactness, no galvanizing leakage, regular surface, uniform coating and corrosion resistance. The invention is suitable for hot-galvanizing an alloy layer on an iron surface.

Owner:XINGCHENG YUEJIN GALVANIZING

Long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping

ActiveCN105648377AReduce performanceWill not use reduced effectHot-dipping/immersion processesAlkali freeSurface-active agents

The invention discloses a long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping. The plating assistant agent is prepared from the following raw materials in percentage by weight: 25 percent to 35 percent of ZnCl2, 2 percent to 10 percent of KF, 5 percent to 15 percent of CaCl2, 4.5 percent to 8.5 percent of AgCl, 2 percent to 3.5 percent of alkali-free SP binary compound flooding dispersing agent, 0.1 percent to 0.5 percent of compound surface active agent and the balance water. Through a reasonable formula of the plating assistant agent, a zinc-aluminum-magnesium alloy coating is obtained on the surface of a steel and iron material substrate by utilizing hot dipping; the coating and the steel and iron material substrate separately keep original performance; the coating is compact in structure and free of skip plating, and zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance can be formed. The plating assistant agent is low in cost, can be easily produced industrially, and can be widely suitable for hot dipping long-ageing reusable zinc-aluminum-magnesium alloy plating solution of which the Al content is 5 percent to 22 percent and the Mg content is 2 percent to 6 percent.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

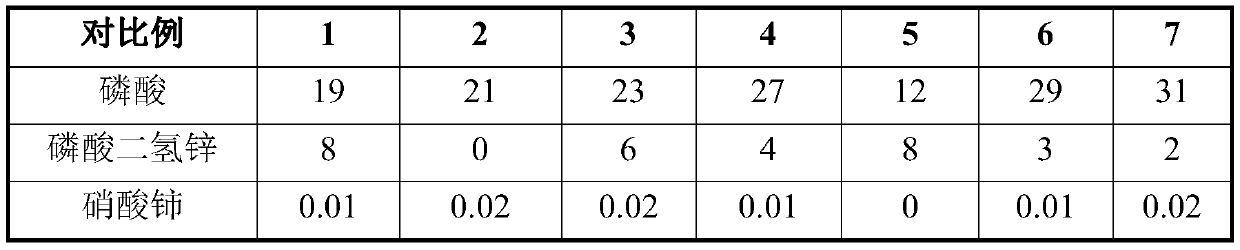

Environment-friendly rust removing and resisting agent applied to acid pickling

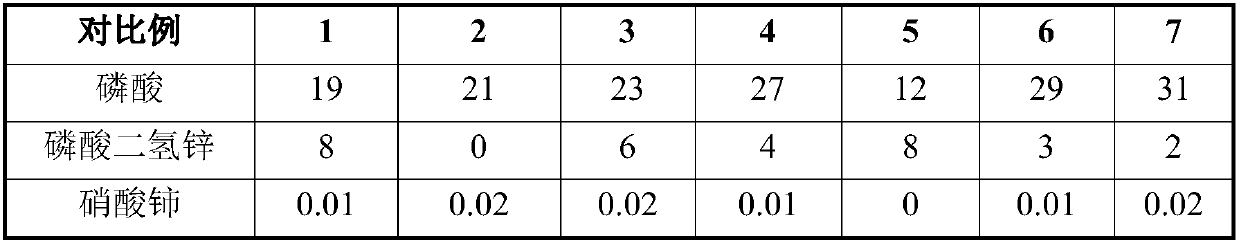

The invention relates to an environment-friendly rust removing and resisting agent applied to acid pickling. The rust removing and resisting agent is prepared from the following raw materials in percentage by mass: 17-35% of phosphorous acid, 1-8% of zinc dihydrogen phosphate, 1-8% of an oxidant, 1-10% of a complexing agent, 0.05-5% of a passivator, 0.01-2% of a surfactant, 0.01-2% of a corrosioninhibitor and the balance of water, wherein the oxidant is selected from one or two of cerous nitrate or zinc nitrate; the passivator is sodium molybdate; the corrosion inhibitor is selected from oneor two of rodine and benzotriazole; the surfactant is selected from JFC (fatty alcohol-polyoxyethylene ether) and OP-10 (alkylphenol polyethylene ether). Through the rust removing and resisting agent,the rust removing and resisting effect can be achieved by carrying out acid pickling under the normal temperature; a good galvanization effect can also be achieved after steel products are placed inthe air for a period of time after removing rust; meanwhile, the rust removing and resisting agent has the advantages of low production cost, simple operation process, no harm to operators and environment friendliness.

Owner:工大高腾科技江苏有限公司

Hot galvanizing technology process for steel iron plate

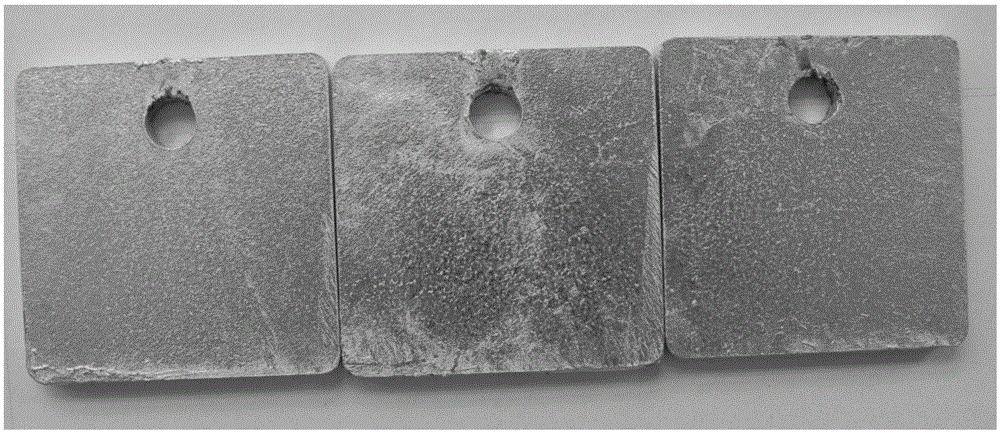

InactiveCN106282871ANo missing platingSuperficial rulesHot-dipping/immersion processesAlloyCorrosion

The invention discloses a hot galvanizing technology process for a steel iron plate. A hot galvanizing technology comprises the following steps of degreasing, acid pickling, plating auxiliary soaking, drying preheating, heat plating, organizing, passivating, cooling and inspecting. By means of the hot galvanizing technology, a plating layer of a workpiece has the advantages of being compact, free of skip plating, regular in surface, uniform and resistant to corrosion, and the hot galvanizing technology is suitable for being applied to a hot galvanizing alloy layer on the surface of steel iron.

Owner:周峰

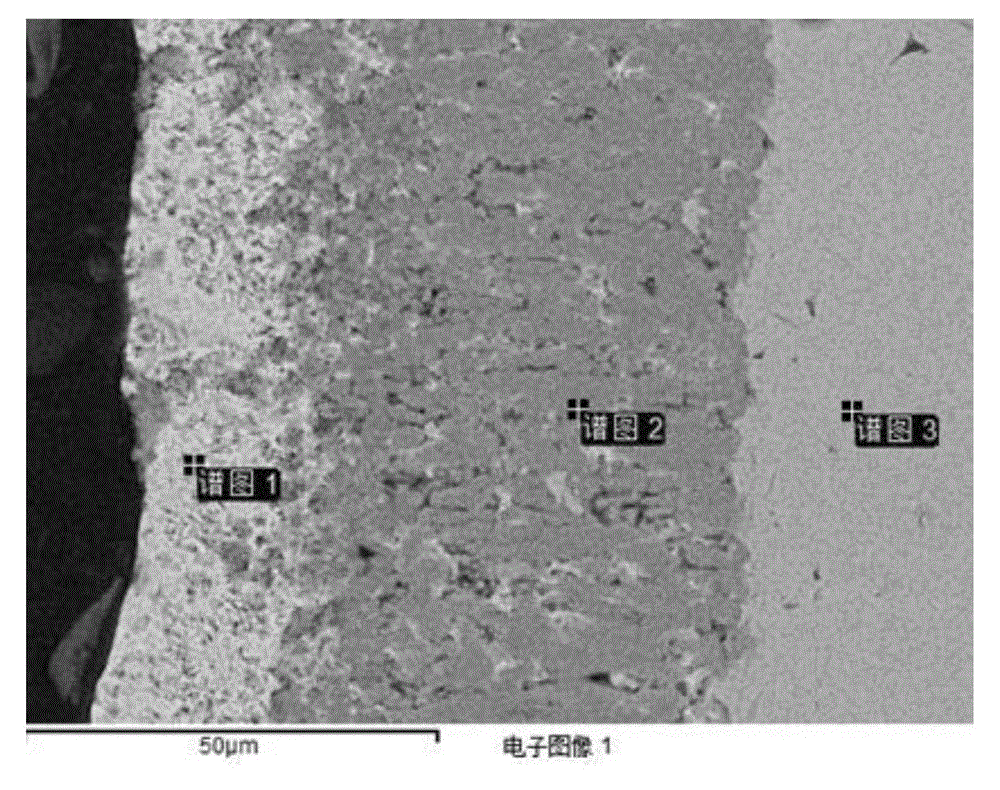

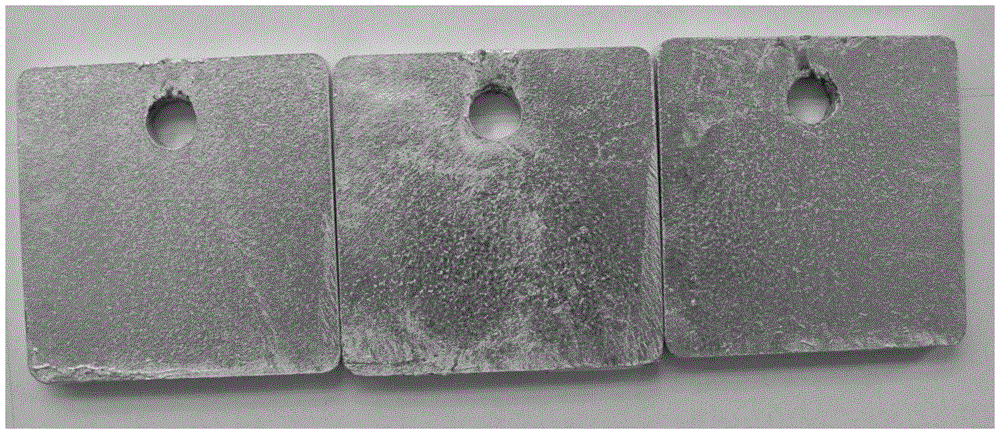

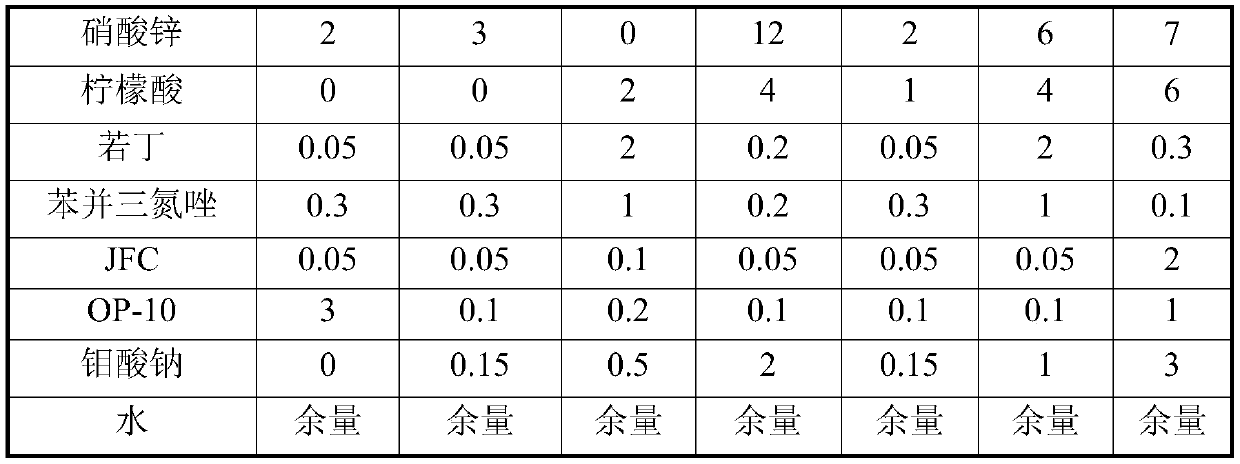

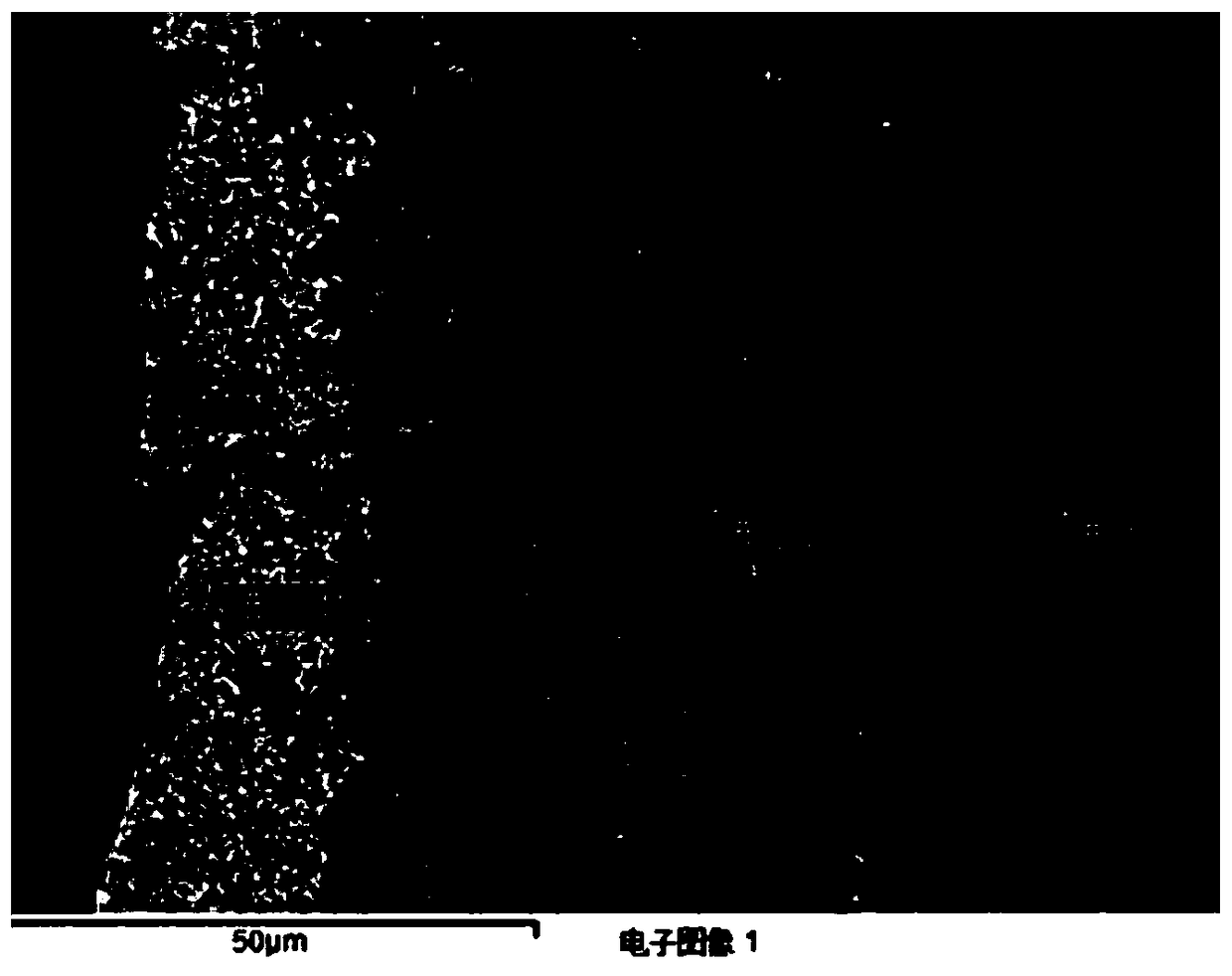

Single plating type zinc-aluminum-magnesium-rare earth protection coating with high corrosion resistance and preparation technology

ActiveCN105063532AGood lookingAchieve surface single platingHot-dipping/immersion processesRare earthAlloy coating

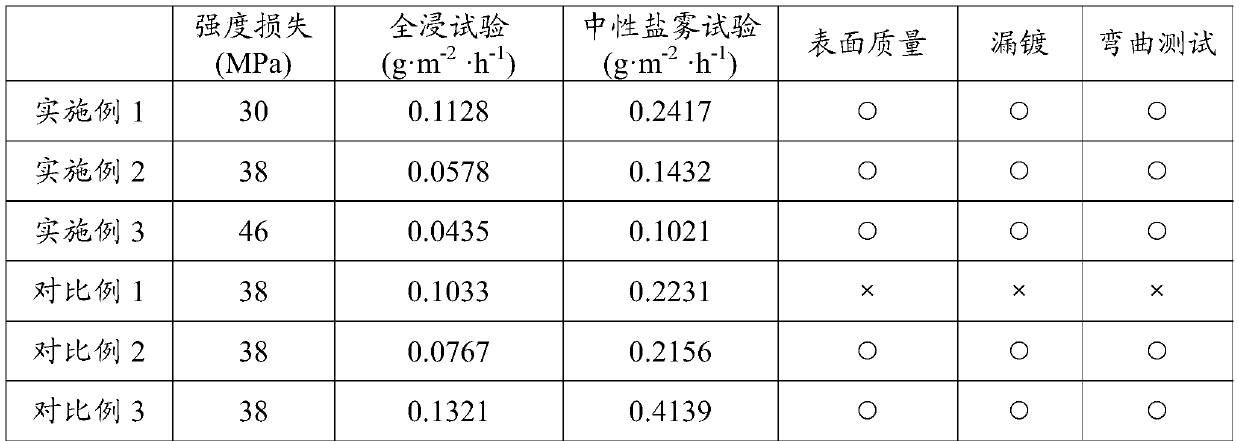

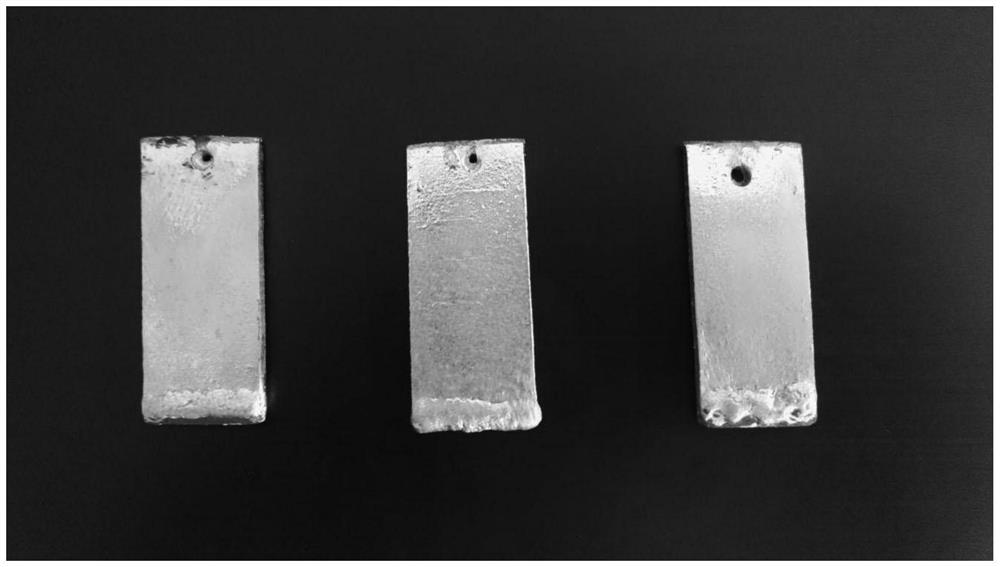

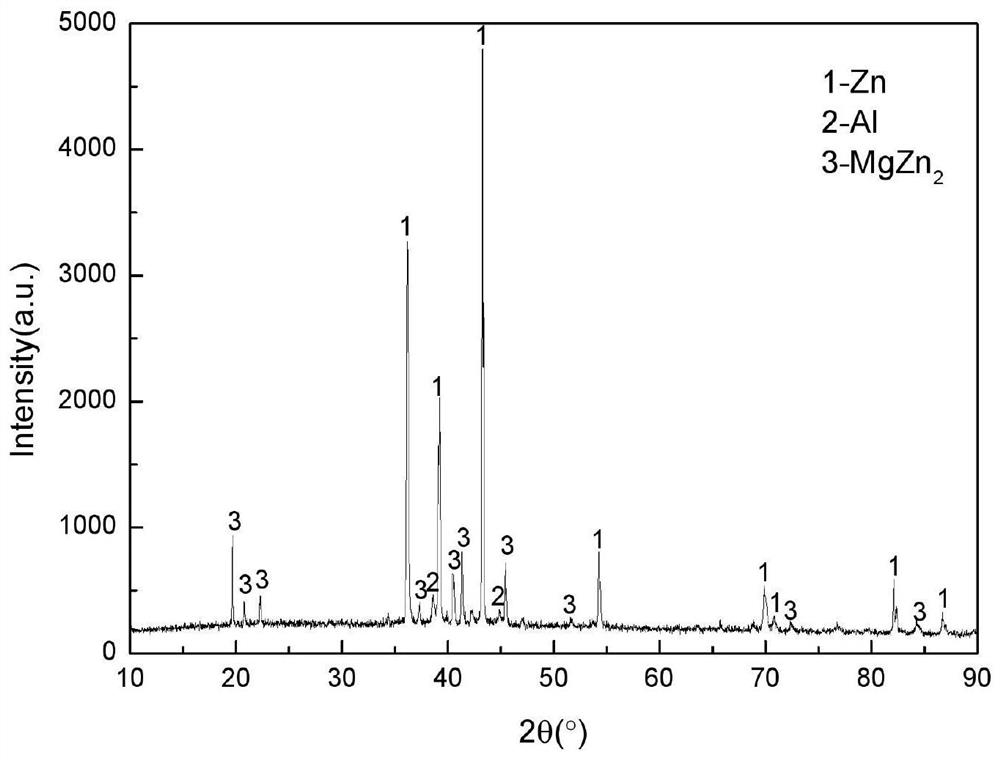

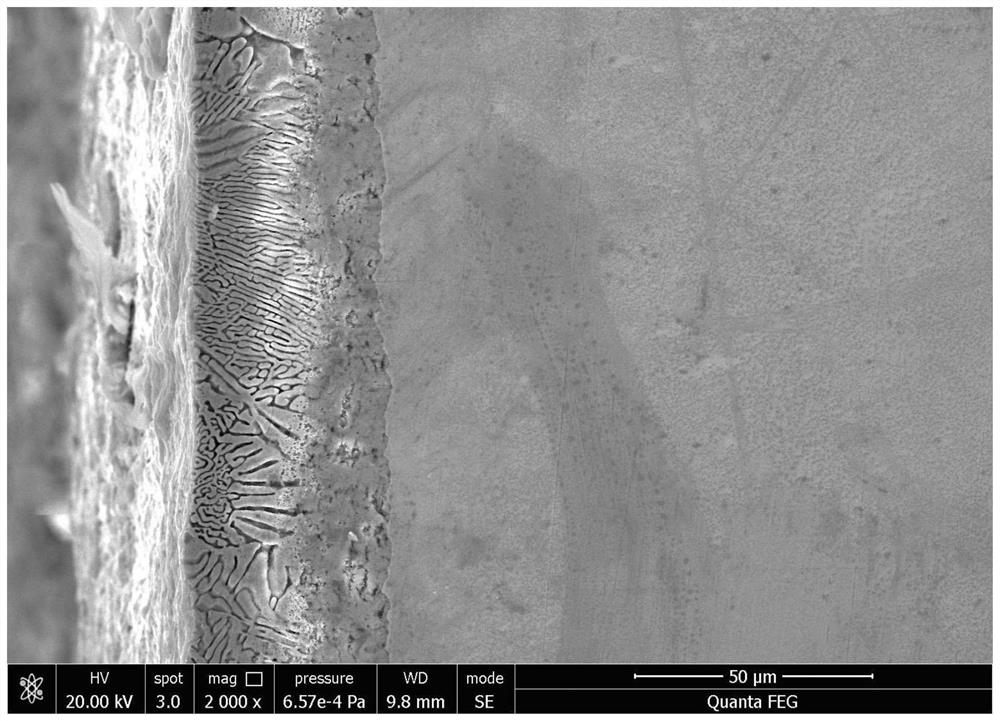

The invention discloses a single plating type zinc-aluminum-magnesium-rare earth protection coating with high corrosion resistance and a preparation technology. According to the single plating type zinc-aluminum-magnesium-rare earth protection coating technology, a zinc-aluminum-magnesium alloy coating can be acquired on a metal surface with a single hot dipping method; respective original performance of the coating and a metal matrix are kept, but the coating and the metal matrix form a metallurgical bonding interface of more than 99.9%, meanwhile, the coating is compact in structure, has stable components and excellent corrosion resisting performance and avoids skip plating, and salt-spray corrosion reaches 2,060 h; the corrosion resistance of the alloy coating is better than that of a common hot dipping pure-zinc coating, and the service life is prolonged. The single plating type technology can be reused and applicable to industrial production, overcomes defects that assistant plating of metal and a zinc-aluminum-magnesium alloy liquid is difficult, an excellent metallurgical bonding interface between the metal and the zinc-aluminum-magnesium alloy liquid is difficult to form, the probability of skip plating is high and the like, and can be widely applicable to preparation of a zinc-aluminum-magnesium alloy plating solution containing 5%-12% of Al and 1%-6% of Mg on the metal surface; a prepared co-penetrated layer forms Zn / Al / MgZn2 ternary eutectic and multiple types of binary eutectic, and the eutectic is the major reason for guaranteeing high corrosion resistance of the co-penetrated layer.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Aqueous fusion agent used for flux method hot dip coating low aluminium zinc alloy and its application method

InactiveCN1442503AImprove activation abilityImprove solubilityHot-dipping/immersion processesCeriumZinc alloys

An aqueous flux for hot dip coating of low-Al Zn alloy by flux method is prepared from zinc chloride (70-80 mass%), ammonium chloride (8-10 mass%) and cerium chloride (4-10 mass%). Said hot dip coating process includes such steps as removing oil and rust from the iron or steel workpiece, immersing it in said aqueous flux for a certain time, baking at 120-160 deg.c, and immersing in molten Zn-Al alloy.

Owner:UNIV OF SCI & TECH BEIJING

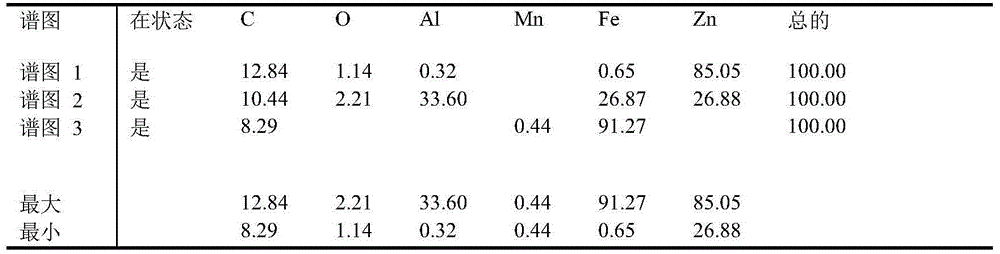

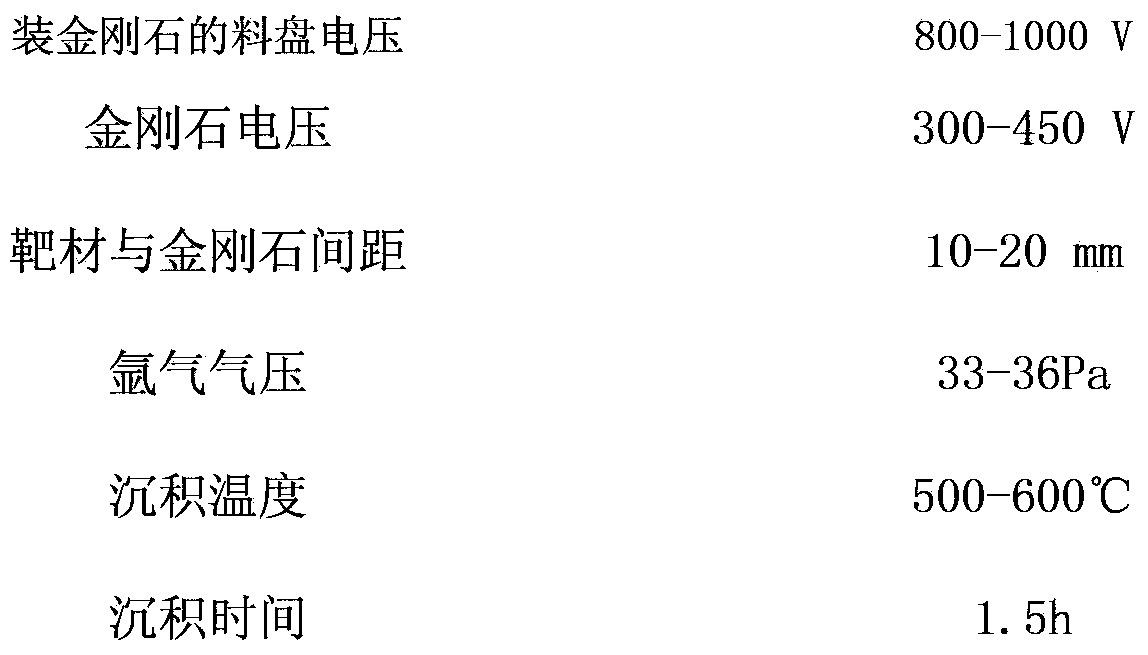

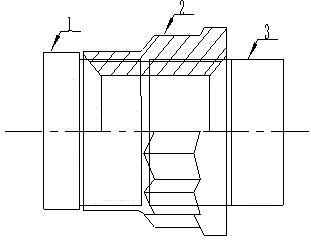

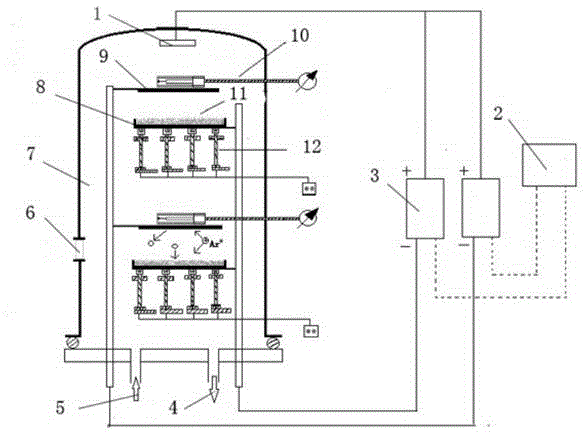

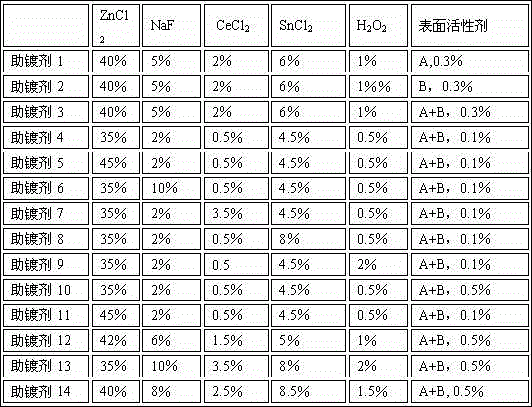

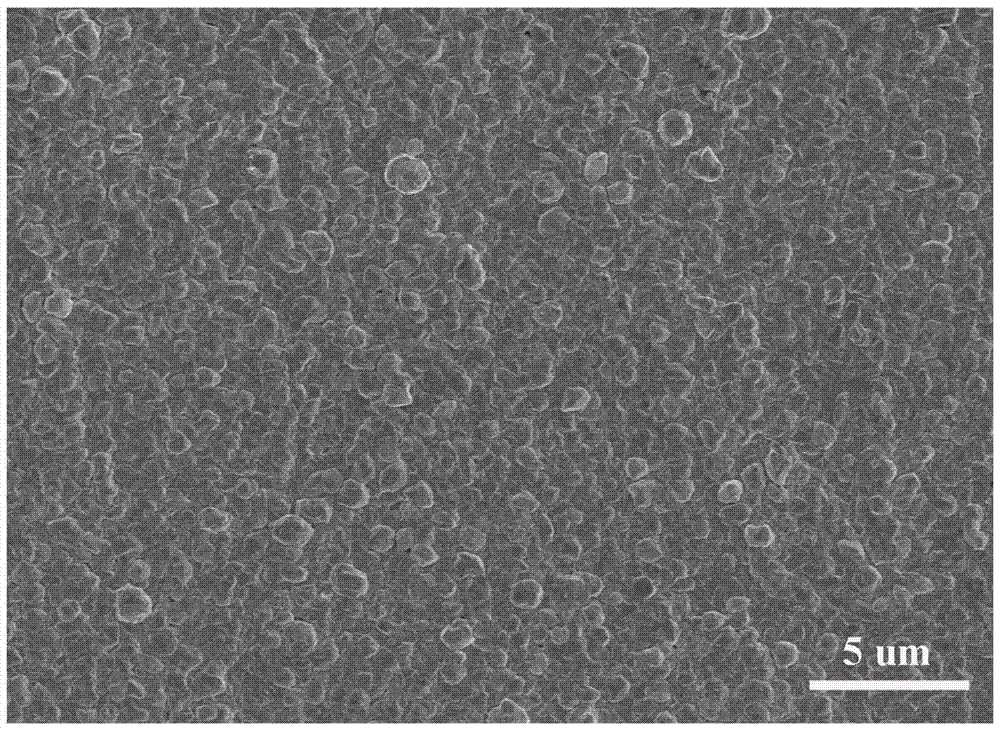

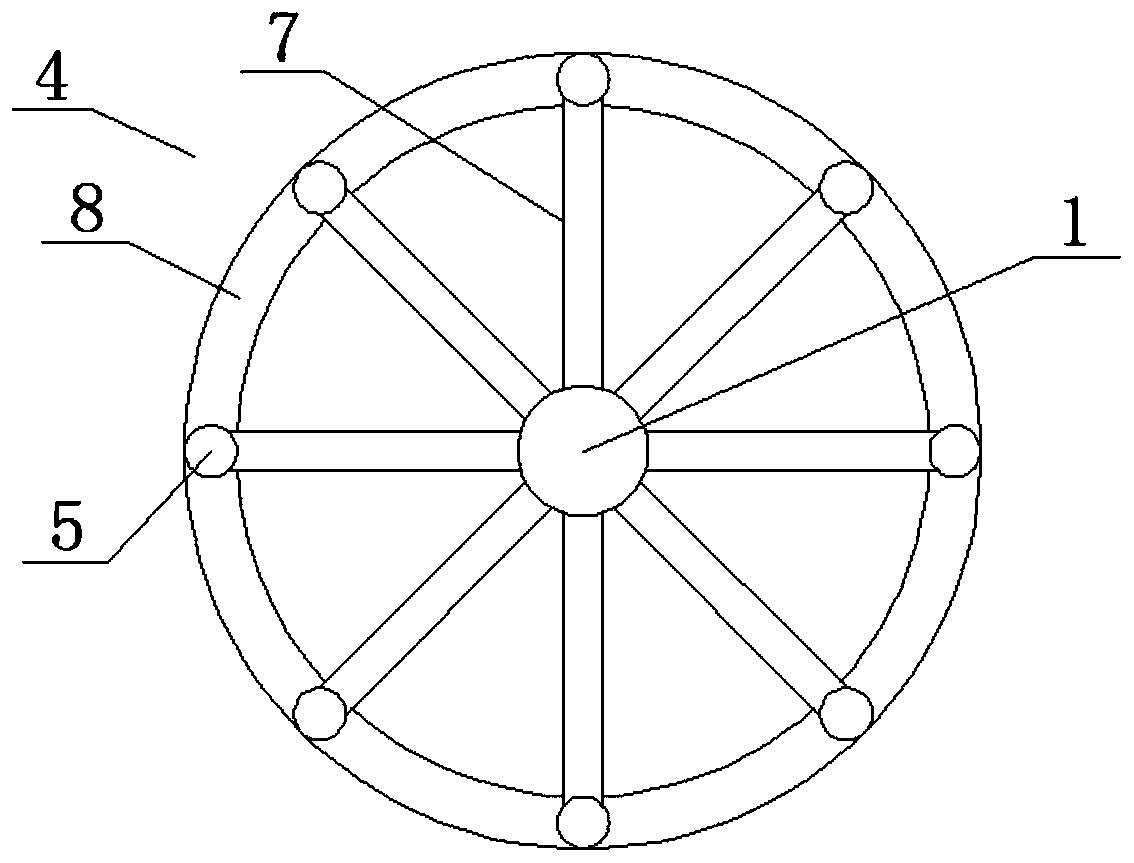

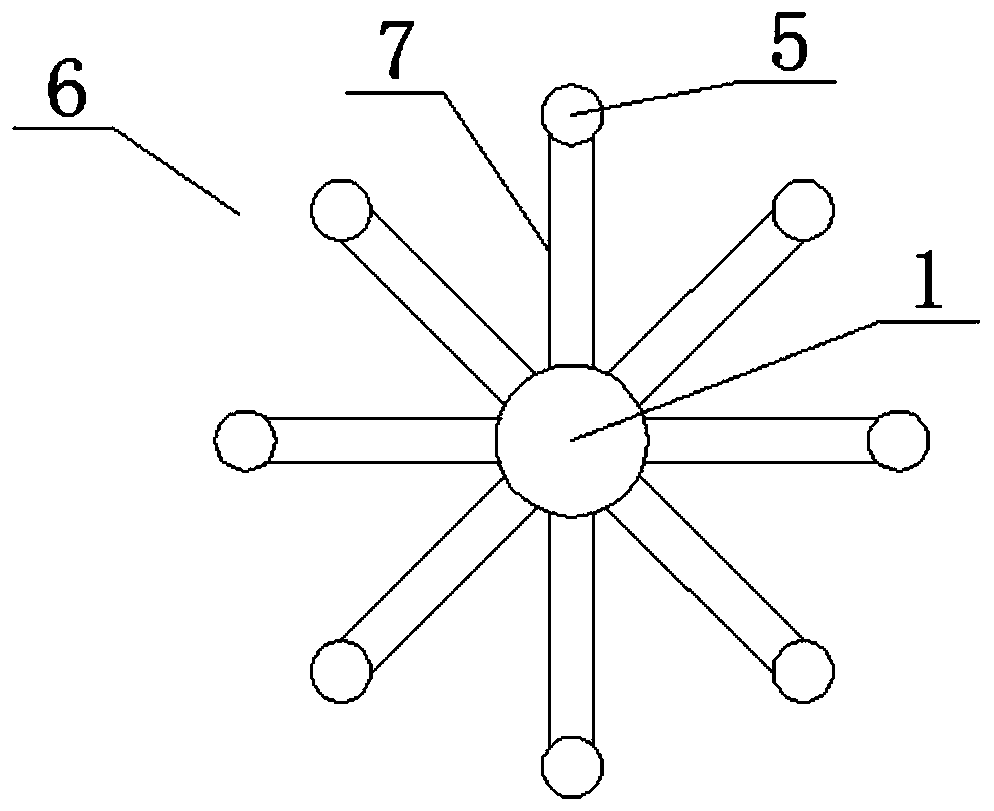

Equipment for depositing nano coating of double-cathode plasma on surface of diamond and process

InactiveCN103361615AImprove uniformityImprove the deposition effectVacuum evaporation coatingSputtering coatingIon depositionSputter deposition

The invention discloses equipment for preparing a nano coating on the surface of diamond by means of double-cathode plasma sputtering deposition, and a preparation process of the equipment. The equipment comprises a vacuum chamber, a double-cathode structure, a target device, a material disc, an oscillator, a gas inlet and a gas outlet, wherein the double-cathode structure comprises two anodes and two cathodes, wherein one of the cathodes is connected with the target device, and the other cathode is connected with the material disc. A coating is formed on the surface of the diamond through target metal by adopting the double-cathode plasma sputtering deposition means, by adjusting the voltages of a target and the material disc and the distance between the target and the diamond in the material disc, and by controlling the deposition time and the temperature. Due to the double-cathode plasma sputtering deposition means, the prepared coating and the diamond have good bonding force.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Novel plating auxiliary for single hot-dipping of Galfan alloy in solvent method and a preparation method thereof

ActiveCN108624831AQuality improvementGuaranteed Metallurgical BondingHot-dipping/immersion processesZinc bromidePotassium fluoride

The invention provides a novel plating auxiliary for single hot-dipping of a Galfan alloy in a solvent method and a preparation method thereof. According to the plating auxiliary, per liter of the plating auxiliary is prepared from the following components of 100-150 g / L of ZnCl2, 50-100 g / L of ZnBr, 10-20 g / L of SnCl, 8-12 g / L of KF, 0-0.5 g / L of bismuth chloride, 0.5-2 g / L of sodium borohydride,0.1-0.3 g / L of hydrochloric acid, 5-15 g / L of active alkali metal chloride salt and the balance water. The plating auxiliary has the advantages that the zinc bromide, the sodium borohydride and the potassium fluoride are introduced into the plating auxiliary, so that a surfactant and rare-earth chloride which are expensive in price are avoided, the application range is wider, almost all steel products are covered, and therefore the problems of serious skip plating, air holes, list edges, slag inclusion and the like in the Galfan alloy hot-dipping process in the prior art can be effectively solved; and the plating auxiliary can play a good plating assisting role when being used at room temperature, the production cost is greatly saved, the components of the plating auxiliary are stable, the cost is low, and industrial popularization is facilitated.

Owner:HEBEI UNIV OF TECH

Aqueous fusion agent used for flux method hot dip coating low aluminium zinc alloy and its application method

InactiveCN1186473CImprove activation abilityImprove solubilityHot-dipping/immersion processesCeriumZinc alloys

An aqueous flux for hot dip coating of low-Al Zn alloy by flux method is prepared from zinc chloride (70-80 mass%), ammonium chloride (8-10 mass%) and cerium chloride (4-10 mass%). Said hot dip coating process includes such steps as removing oil and rust from the iron or steel workpiece, immersing it in said aqueous flux for a certain time, baking at 120-160 deg.c, and immersing in molten Zn-Al alloy.

Owner:UNIV OF SCI & TECH BEIJING

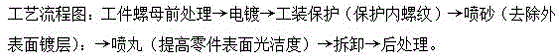

Process for local electroplating of internal threads of nut

Provided is a process for local electroplating of internal threads of a nut. The workpiece nut is completely electroplated, and then protection, abrasive blasting, shot blasting, disassembly and aftertreatment are carried out. The process comprises the steps of pretreatment of the workpiece nut, electroplating, tool protection of the internal threads, abrasive blasting for removing plating layers on the outer surface, shot blasting for improving the surface smoothness of the part, disassembly, and aftertreatment. A protection tool is made of a nylon material and is in close fit through threads, and the two ends for tool protection are tightened in the protection process so that the protection tool can be prevented from falling and damaging plating layers of the internal threads in the abrasive blasting and shot blasting processes; the batches of plating layers can be rapidly removed through abrasive blasting, and the glossiness of the surface of the part can be improved and the roughness of the surface of the part can be reduced through shot blasting. The process is easy and convenient to implement, high in efficiency, free of plating missing, discoloration, corrosion and plating layer unevenness, low in cost, small in pollution, capable of achieving the qualified rate higher than 99% and high in universality, and can be applied to local electroplating of internal thread or external thread fasteners.

Owner:GUIZHOU HANGRUI AVIATION PRECISION PARTS MFG

Novel and efficient structural part hot dip Galfan promotion flux and preparation method and application thereof

The invention discloses novel and efficient structural part hot dip Galfan promotion flux and preparation method and application thereof. The promotion flux includes zinc chloride, ammonium chloride,alcohol, rare earth chloride and water. The preparation method of the novel and efficient structural part hot dip Galfan promotion flux includes the following steps that (1), preparation of an alcoholic solution, (2), preparation of an aqueous solution, and (3), preparation of the promotion flux. According to the novel and efficient structural part hot dip Galfan promotion flux, the rare earth chloride is added to the promotion flux, halogen compounds are led in, generation of A1c13 smoke is effectively restrained, the rare earth element has surface activity, wettability on the surface of steel substrate is increased, the phenomenon of skip plating is effectively reduced, and an ideal coating layer is obtained accordingly.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD

Non-palladium activation copper plating process and sensitizer and activator thereof

ActiveCN111763930AReduce manufacturing costQuick responseLiquid/solution decomposition chemical coatingPhosphoric Acid EstersPhosphate

The invention provides a non-palladium activation copper plating process. The process comprises the following steps of S1, removing oil; S2, coarsening, coarsening a workpiece by adopting a coarseningsolution, and then carrying out ultrasonic washing; S3, sensitizing, putting the washed workpiece into a sensitizer to be sensitized, wherein the sensitizer is prepared from the following componentsof, in concentration ratio, 5-100g / L of tin methanesulfonate, 1-50g / L of tartaric acid, 1-10g / L of ascorbic acid, 5-50g / L of citric acid, 1-20g / L of 2, 4-aminopyridine, 1-10ml / L of an amino silane coupling agent and 1-10ml / L of a surfactant; S4, activating, putting the sensitized workpiece into an activating agent to be activated, wherein the activating agent is prepared from the following components of, in concentration ratio, 1-20g / L of silver nitrate, 1-50ml / L of ammonia water, 1-50g / L of EDTA, 1-20ml / L of triethanolamine, 0.5-5g / L of 2, 4-aminopyridine and 0.1-10ml / L of phosphate surfactant; S5, pre-coppering; and S6, thickening-copper. The invention provides the non-palladium activated copper plating process, the sensitizer and the activating agent thereof which is low in production cost, good in plating bonding force, green and environment-friendly.

Owner:赤壁市聚茂新材料科技有限公司

No-zinc-ammonium hot-dip galvanizing smokeless promotion flux

ActiveCN108179368AAddressing the Root Cause of Volatile SmokeSolve the root causeHot-dipping/immersion processesAlkaline earth metalCerium

The invention discloses a no-zinc-ammonium hot-dip galvanizing smokeless promotion flux comprising 100-210 g / L of alkaline earth metal chloride, 10-40 g / L of alkali chloride, 20-60 g / L of cerium chloride, 5-20 g / L of alkali metal fluoride, 5-10 g / L of hydroxylamine hydrochloride, 0-30 g / L of alkali metal hydroxide, 1-10 g / L of anionic surfactant, 1-5 g / L of a nonionic surfactant, and the balance water. The technical formula does not contain zinc chloride and ammonium chloride, after the treatment of promotion flux, the hot-dip galvanizing process has no smoke volatilization, and the zinc ingotconsumption can be obviously reduced, and positive accelerations of improving the production environment and reducing the production cost are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

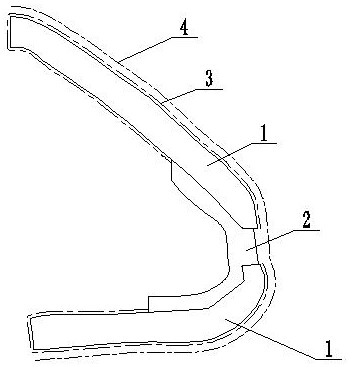

Automobile lamp mask and production process thereof

PendingCN112721033AEffective protectionUnique exterior effectLiquid surface applicatorsCoatingsMechanical engineeringVarnish

The invention belongs to the technical field of automobile decoration accessories, and particularly relates to an automobile lamp mask and a production process thereof. According to the automobile lamp mask and the production process thereof, the coexistence of a light-emitting area and an electroplating effect is realized at the same time, the light-emitting area can resist UV and scratch, and the electroplating area is resistant to corrosion and weather. The automobile lamp mask comprises a mask body, and is characterized in that the mask body is formed by combining a light-transmitting material part and an electroplating base material part which are subjected to multi-color injection molding into a whole; and an electroplating layer is arranged on the surface of the electroplating base material part, and varnish layers are arranged on the outer side surfaces of the electroplating layer and the light-transmitting material part.

Owner:沈阳道达汽车饰件有限公司

A kind of solvent method single plating galfan alloy plating flux and preparation method thereof

ActiveCN108624831BQuality improvementGuaranteed Metallurgical BondingHot-dipping/immersion processesZinc bromideChloride salt

The invention provides a novel plating auxiliary for single hot-dipping of a Galfan alloy in a solvent method and a preparation method thereof. According to the plating auxiliary, per liter of the plating auxiliary is prepared from the following components of 100-150 g / L of ZnCl2, 50-100 g / L of ZnBr, 10-20 g / L of SnCl, 8-12 g / L of KF, 0-0.5 g / L of bismuth chloride, 0.5-2 g / L of sodium borohydride,0.1-0.3 g / L of hydrochloric acid, 5-15 g / L of active alkali metal chloride salt and the balance water. The plating auxiliary has the advantages that the zinc bromide, the sodium borohydride and the potassium fluoride are introduced into the plating auxiliary, so that a surfactant and rare-earth chloride which are expensive in price are avoided, the application range is wider, almost all steel products are covered, and therefore the problems of serious skip plating, air holes, list edges, slag inclusion and the like in the Galfan alloy hot-dipping process in the prior art can be effectively solved; and the plating auxiliary can play a good plating assisting role when being used at room temperature, the production cost is greatly saved, the components of the plating auxiliary are stable, the cost is low, and industrial popularization is facilitated.

Owner:HEBEI UNIV OF TECH

A kind of electroplating solution additive for electroplating bright nickel-titanium alloy

The invention provides an electroplating solution bright additive and auxiliary additive for electroplating a bright nickel-titanium alloy. The bright additive is composed of 30-40 g / L propane sulfonate pyridine, 40-50 g / L propane alcohol ethoxy ether, 30-50 g / L N,N-diethylallylene amine formate, 5-10 g / L propiolic alcohol, 10-12 g / L sodium hydroxymethyl sulfonate and the balance of distilled water or deionized water. The auxiliary additive is composed of 180-200 g / L saccharin (or soluble saccharin), 200-250 g / L dilute sodium propyl sulfonate (35%), 5-10 g / L sodium hydroxypropyl thiosulfate and the balance of distilled water or deionized water. The additives are simple in components, non-toxic and pollution-free, and free of Cr<6+>.When the invention is used for electroplating the bright nickel-titanium alloy, the wear resistance, corrosion resistance and toughness of the coating are greatly enhanced. The invention has very important actions in common industry and in the fields of military affairs, national defense, aerospace and submarine ships.

Owner:湖北广志科技服务有限公司

A long-term and reusable flux for hot-dip galvanizing aluminum-magnesium alloys

ActiveCN105648377BReduce performanceWill not use reduced effectHot-dipping/immersion processesAlkali freeSurface-active agents

The invention discloses a long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping. The plating assistant agent is prepared from the following raw materials in percentage by weight: 25 percent to 35 percent of ZnCl2, 2 percent to 10 percent of KF, 5 percent to 15 percent of CaCl2, 4.5 percent to 8.5 percent of AgCl, 2 percent to 3.5 percent of alkali-free SP binary compound flooding dispersing agent, 0.1 percent to 0.5 percent of compound surface active agent and the balance water. Through a reasonable formula of the plating assistant agent, a zinc-aluminum-magnesium alloy coating is obtained on the surface of a steel and iron material substrate by utilizing hot dipping; the coating and the steel and iron material substrate separately keep original performance; the coating is compact in structure and free of skip plating, and zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance can be formed. The plating assistant agent is low in cost, can be easily produced industrially, and can be widely suitable for hot dipping long-ageing reusable zinc-aluminum-magnesium alloy plating solution of which the Al content is 5 percent to 22 percent and the Mg content is 2 percent to 6 percent.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Equipment and technology of dual-cathode plasma deposition nano-coating on diamond surface

InactiveCN103361615BImprove uniformityImprove the deposition effectVacuum evaporation coatingSputtering coatingSputter depositionVacuum chamber

The invention discloses equipment for preparing a nano coating on the surface of diamond by means of double-cathode plasma sputtering deposition, and a preparation process of the equipment. The equipment comprises a vacuum chamber, a double-cathode structure, a target device, a material disc, an oscillator, a gas inlet and a gas outlet, wherein the double-cathode structure comprises two anodes and two cathodes, wherein one of the cathodes is connected with the target device, and the other cathode is connected with the material disc. A coating is formed on the surface of the diamond through target metal by adopting the double-cathode plasma sputtering deposition means, by adjusting the voltages of a target and the material disc and the distance between the target and the diamond in the material disc, and by controlling the deposition time and the temperature. Due to the double-cathode plasma sputtering deposition means, the prepared coating and the diamond have good bonding force.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of plating flux for steel wire hot-dip galvanized aluminum-magnesium alloy

ActiveCN103510031BReduce pollutionImprove bindingHot-dipping/immersion processesMg alloysSurface-active agents

The invention relates to a plating flux for hot-dipping galvanized aluminum-magnesium alloys of steel wires, and belongs to the technical field of iron and steel material surface coating processes. The plating flux of the present invention consists of: ZnC2 35%-45%; NaF 2%-10%; CeCl2 0.5-3.5%; SnCl2 4.5%-8.5%; H2O2 0.5-2%; Surfactant 0.1%-0.5% , and the balance is water; the surfactant is sodium fatty alcohol ether sulfate and / or sodium dodecylsulfonate. In the invention, a zinc-aluminum-magnesium alloy coating is obtained by hot-dip plating on the steel wire surface through a reasonable formula of plating flux. The coating and the steel wire each maintain their original performance, with more than 99.9% of the metallurgical bonding interface, the coating structure is dense, there is no missing plating, and it can form a zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance. The corrosion resistance of the alloy coating is 2 to 4 times that of the ordinary hot-dip pure zinc coating. The plating flux has low cost, can be used repeatedly and is easy for industrial production.

Owner:STATE GRID CORP OF CHINA +1

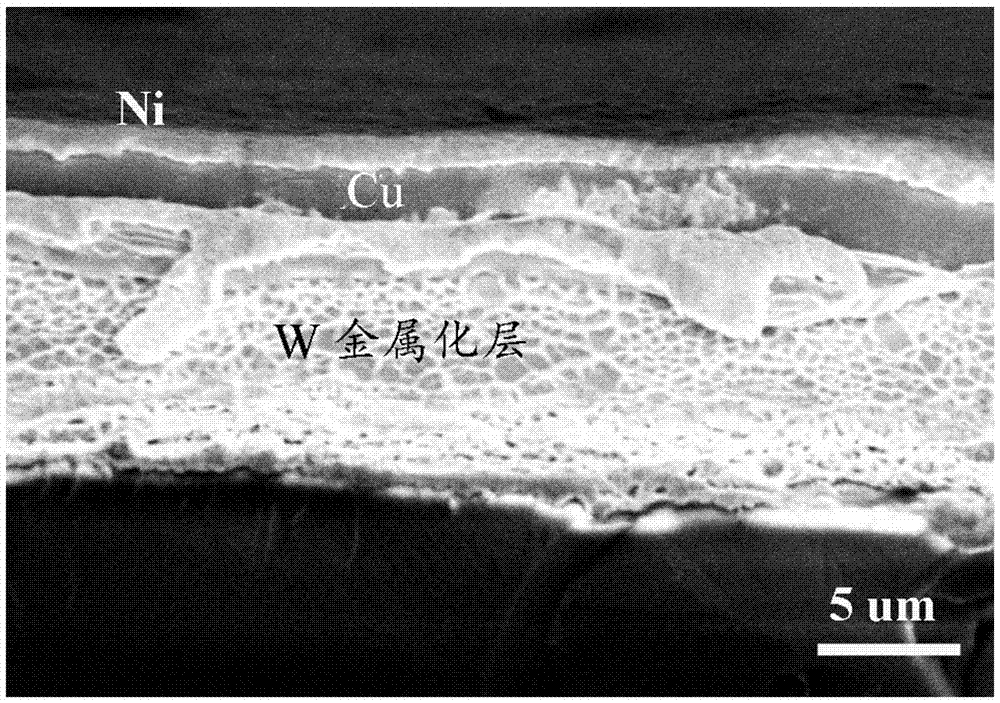

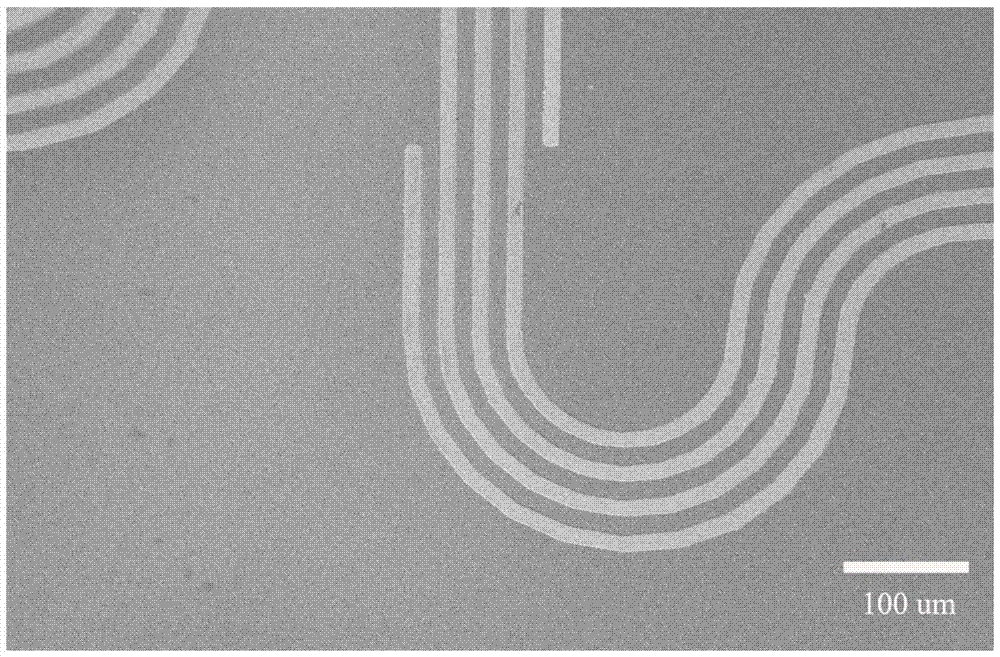

A method for secondary metallization and nickel plating on the surface of high temperature co-fired ceramics

ActiveCN105200400BHas a hydrophilic effectUniform activation treatmentLiquid/solution decomposition chemical coatingElectroless nickelCopper plating

The invention relates to a nickel-plating method for the surface of a high-temperature co-fired ceramic tungsten metallized conductor layer. The specific operation steps are as follows: Alkaline degreasing, acid micro-etching, sensitization activation, electroless copper plating, surface adjustment treatment, alkaline electroless nickel plating on the tungsten conductor material of primary metallization of high temperature co-fired ceramics. A nickel material layer with a thickness of 2 to 3 μm is formed on the surface of the tungsten conductor of the primary metallization of high temperature co-fired ceramics. The strong oxidizing property of the acid is used to slightly corrode the surface of the tungsten metallized conductor layer to achieve microcosmic roughening and hydrophilic effect. The one-step method of sensitization and activation is used to form a palladium salt center with catalytic activity on the surface of the material; the surface adjustment treatment is used to form a good solid solution diffusion between the acidic chemical nickel coating and the substrate, and the interface bonding force is enhanced; the two-step copper plating is used The method of combining nickel to form a multi-layer metal layer can enhance the adhesion between the coatings on the surface of the material, release the stress of the coating, and the obtained coating has good appearance quality and excellent solderability.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

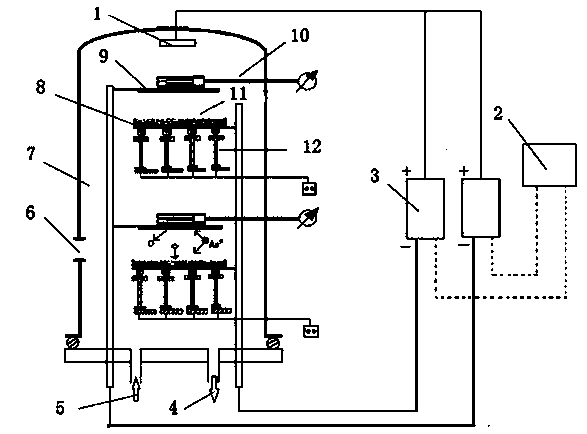

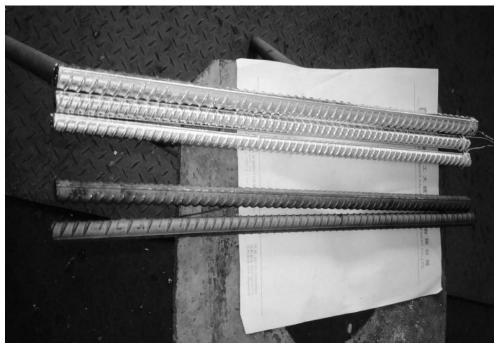

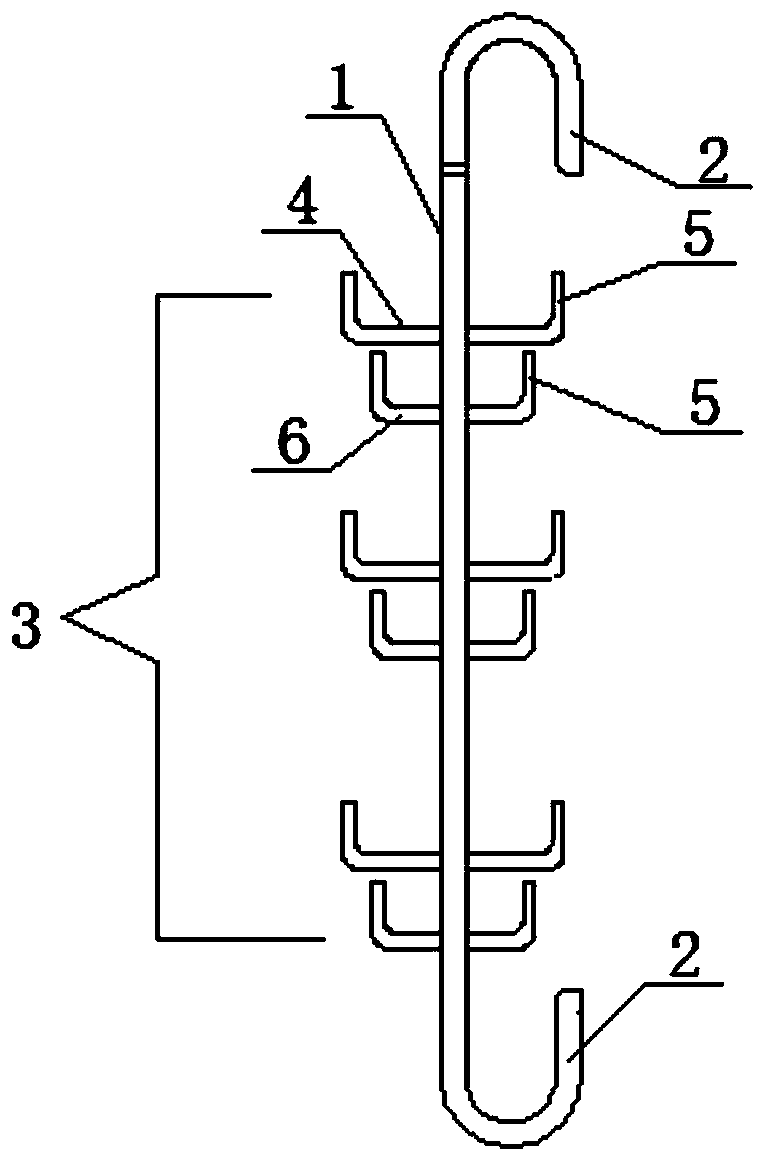

Technological method of steel wire overlay galfan alloy and its equipment

InactiveCN100336932CSolving Combined Single Plating Process IssuesSolve the problem of single plating processHot-dipping/immersion processesElectrolysisSulfate

A process for plating Galfan alloy on the surface of steel wire includes such steps as paying off, degreasing, pickling, water washing, preplating in electrolytic liquid prepared from zinc sulfate, catalyst GD-L and water, baking, hot dipping for plating, vertically leading out, wiping, forced cooling and winding. In said hot dipping step, an internal heater made of anticorrosion alloy pipe is used.

Owner:HEBEI UNIV OF TECH

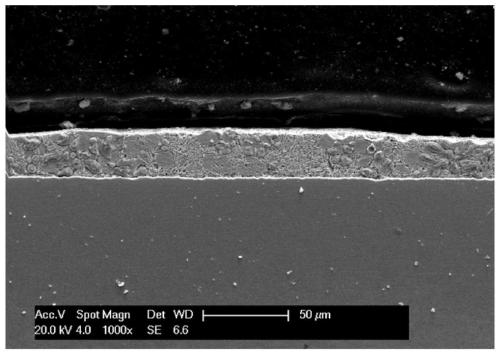

A kind of hot-dip galvanized aluminum-magnesium alloy coating and its preparation method and application

ActiveCN109252125BMeet the needs of high comprehensive performanceThickness is easy to controlHot-dipping/immersion processesChemical compositionAlloy coating

Owner:SOUTHEAST UNIV

A kind of preparation method of environment-friendly zinc-aluminum-magnesium alloy coated steel plate

ActiveCN109023197BHarm reductionQuality improvementHot-dipping/immersion processesElectrolysisPre treatment

The invention provides a preparation method of an environment-friendly zinc-aluminum-magnesium alloy coated steel plate. The preparation method comprises the steps of conducting pretreatment on a hotrolled low-carbon steel plate through mechanical derusting and electrolytic degreasing, heating the steel plate through a high-frequency induction heating device and conducting reduction on the pretreated steel plate in an N2-H2 mixed atmosphere to obtain a proper hot dip-coated surface; cooling the steel plate in an N2 atmosphere, controlling the temperature of the steel plate before dip platingand conducting dip plating in a zinc-aluminum-magnesium alloy plating solution; and then cooling the steel plate in the air. Through the preparation method, harm of pollutants generated in the traditional acid pickling, derusting and assistant plating process to human bodies and environments is avoided; the more and more strict requirements for environmental protection are met; the quality of a plating layer is improved, and the preparation method has broad application prospects.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

Plating auxiliary of hot-dipped galvanized aluminum alloy plating layer

InactiveCN108300954AEnvironmentally friendly materialsExcellent plating effectHot-dipping/immersion processesEtherAlkyl transfer

The invention discloses a plating auxiliary of a hot-dipped galvanized aluminum alloy plating layer. The plating auxiliary is composed of 70-180 g / L of zinc chloride, 10-40 g / L of aluminum chloride, 5-18 g / L of yttrium chloride, 5-16 g / L of calcium chloride, 18-50 g / L of potassium fluoride, 7-20 g / L of stannous chloride, 15-50 g / L of ethyl alcohol, 0.1-8 g / L of polyoxyethylene alkylation ether, 0.1-6 g / L of N-propyl, N-ethoxyl perfluorooctanesulfonamide, 1-8 g / L of hydrogen peroxide and the balance water. The plating auxiliary of the hot-dipped galvanized aluminum alloy plating layer is environment-friendly in material, excellent in plating auxiliary effect, good in smoothness of plating layer and free of plating leaking.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

A kind of environment-friendly pickling derusting antirust agent

ActiveCN107904605BSimple production processTo achieve the effect of rust removal and anti-rustPhosphorous acidPhosphate

Owner:工大高腾科技江苏有限公司

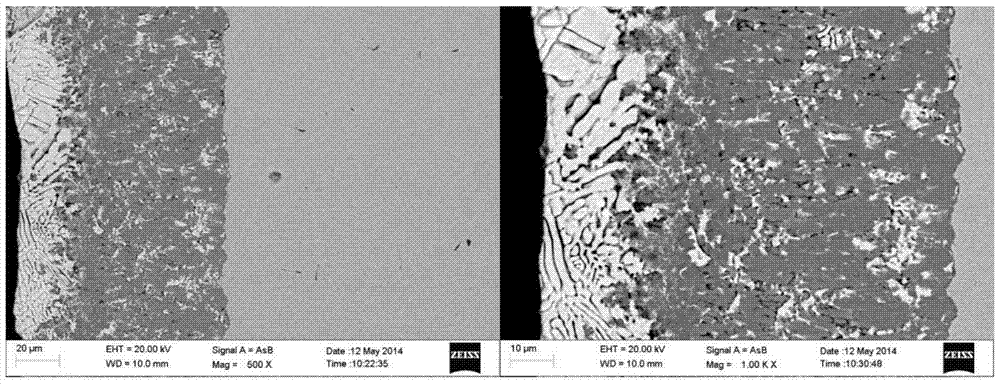

A long-life overhead ground wire and its coating for heavy corrosion environment

ActiveCN105671468BHigh melting pointHigh hardnessHot-dipping/immersion processesInsulated cablesCeriumCoastal zone

The invention discloses an overhead ground wire used in a severe corrosive environment and long in service life and a cladding layer thereof. The cladding layer is prepared from a metal plating solution which is composed of, by weight percentage, 25%-65% of aluminum, 1%-2.5% of magnesium, 0.2%-1.5% of cerium-containing rare earth, 0.1%-0.2% of molybdenum, 0.05%-0.1% of vanadium and the balance zinc. In order to achieve corrosion resistance protection for the overhead ground wire, the anti-corrosion cladding layer which has a high alloy content, meets various property requirements of a zinc, aluminum and magnesium alloy cladding layer, is prepared on the surface of the overhead ground wire and is high in corrosion resistance and long in service life is provided, can be widely applied to the overhead ground wire used in a severe corrosive environment (such as a coastal area, an acid rain area and an industrial pollution area) and meets the requirements that the service life is long, and the maintenance-free time is not less than 15 years.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Zinc electroplating jig for electroplated product

The invention discloses a zinc electroplating jig for an electroplated product. A jig rod is included and provided with clamp hook assemblies and a hanging assembly, and the hanging assembly is provided with hooks. The provided zinc electroplating jig for the electroplated product has the beneficial effects that products cannot be twisted together so that electroplating neglecting of the products can be avoided, and meanwhile mechanical damage is avoided. Product surface electroplating is uniform, electroplating marks cannot be generated, clamp hooks are arranged at the two ends of the jig rod so that the jig can be used front and back, and personnel operation is convenient.

Owner:吴江市东晓表面处理科技有限公司

A high-corrosion-resistant single-coated zinc-aluminum-magnesium rare earth protective coating and its preparation process

ActiveCN105063532BGood lookingAchieve surface single platingHot-dipping/immersion processesBond interfaceRare earth

The invention discloses a highly corrosion-resistant single-coated zinc-aluminum-magnesium rare-earth protective coating and a preparation process thereof. The single-coated zinc-aluminum-magnesium rare-earth protective coating process of the present invention can utilize a single hot dipping method to obtain zinc and aluminum on the metal surface Magnesium alloy coating. The coating and the metal substrate each maintain their original performance, but have more than 99.9% of the metallurgical bonding interface. At the same time, the coating has a dense structure, stable composition, no missing plating, excellent corrosion resistance, and salt spray corrosion up to 2060h. The corrosion resistance of the alloy coating is better than that of ordinary hot-dip pure zinc coating, which improves the service life. The single-plating process can be reused and industrialized, and it overcomes the difficulties of metal and zinc-aluminum-magnesium alloy liquid electroplating. It is difficult to form an excellent bonding interface between the two, and it is easy to produce missing plating. It can be widely used in the preparation of metal surfaces. 5%-12% Al, 1%-6% Mg content of zinc-aluminum-magnesium alloy plating solution, the prepared co-permeation layer forms Zn / Al / MgZn2 ternary eutectic and various types of binary eutectic, which is eutectic The main reason for the high corrosion resistance of the seepage layer.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com