A long-life overhead ground wire and its coating for heavy corrosion environment

A technology for overhead ground wires and corrosive environments, which is applied in coatings, hot-dip plating processes, metal material coating processes, etc., can solve problems such as short service life and poor corrosion resistance, and achieve good wear resistance and excellent corrosion resistance. Effect of thermal shock performance and low expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

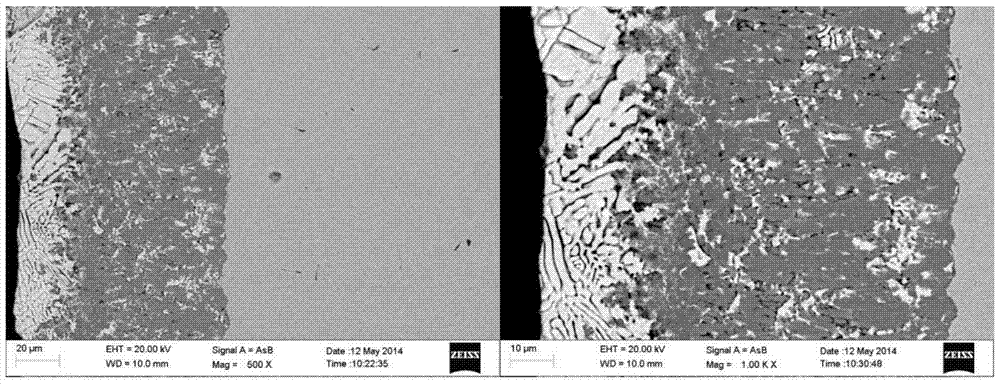

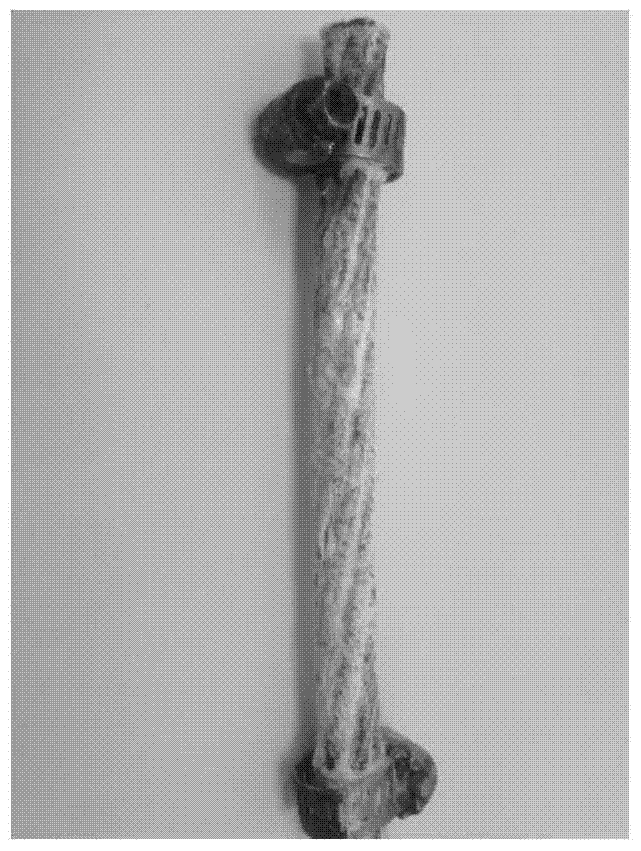

Image

Examples

Embodiment 1

[0037] A preparation process for long-life overhead ground wires used in heavily corrosive environments, the steps are as follows:

[0038] 1) Immerse the steel wire after degreasing, pickling and alkali cleaning in the plating flux at 65°C for 0.5min, and dry to obtain the plating flux; the components of the flux are as follows (in mass percentage): 45% ZnCl 2 , 8% CaF, 1.2% CeCl 2 , 5.5% CaCl 2 , 0.5%H 2 o 2 , 0.1% surfactant (hexamethyldisilazane and sodium dodecylsulfonate are mixed according to the weight ratio of 2:1), and the remainder is tap water;

[0039] 2) Dip the steel wire into the hot-dip alloy bath at an angle of 30° (that is, the angle between the steel wire and the hot-dip alloy liquid surface is 30°), dip-coat at 420°C for 100s, and dry at 120°C;

[0040] Inert gas protection is carried out during the drying process, and the inert gas is Ar+CO 2 The mixed gas, the volume ratio of the two is 2:8, and the gas output is 2L / min, that is;

[0041] The weig...

Embodiment 2

[0044] A preparation process for long-life overhead ground wires used in heavily corrosive environments, the steps are as follows:

[0045] 1) Immerse the steel wire after degreasing, pickling, and alkali cleaning in 85° C. plating flux for 0.3 min, and dry to obtain the flux plating steel wire; the components of the flux flux are as follows (in mass percent): 60% ZnCl 2 , 2% CaF 2 , 4.2% CeCl 2 , 8.5% CaCl 2 , 0.5%H 2 o 2 , 0.2% surfactant (hexamethyldisilazane and sodium lauryl sulfonate are mixed according to the weight ratio of 2.5:1), and the remainder is tap water;

[0046] 2) Dip the help-plating steel wire into the hot-dip alloying solution at an angle of 42° (that is, the angle between the steel wire and the hot-dip alloying liquid surface is 42°), dip-coat at 435°C for 45s, and dry at 130°C. Inert gas protection is carried out during the drying process, and the inert gas is Ar+CO 2 The mixed gas, the volume ratio of the two is 8:2, and the gas output is 5L / min...

Embodiment 3

[0050] A preparation process for long-life overhead ground wires used in heavily corrosive environments, the steps are as follows:

[0051] 1) Immerse the steel wire after degreasing, pickling and alkali cleaning in the plating flux at 100° C. for 0.2 min, and dry to obtain the fluxing steel wire; the components of the fluxing agent are as follows (in mass percentage): 65% ZnCl 2 , 4.8% CaF 2 , 5% CeCl 2 , 1.3% CaCl 2 , 0.5%H 2 o 2 , 0.3% surfactant (hexamethyldisilazane and sodium lauryl sulfonate are mixed according to the weight ratio of 1.5:1), and the balance is tap water;

[0052] 2) Dip the help-plating steel wire into the hot-dip alloying solution at an angle of 42° (that is, the angle between the steel wire and the hot-dip alloying liquid surface is 42°), dip-coat at 470°C for 100s, and dry at 150°C. Inert gas protection is carried out during the drying process, and the inert gas is Ar+CO 2 The mixed gas, the volume ratio of the two is 7:3, and the gas output i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com