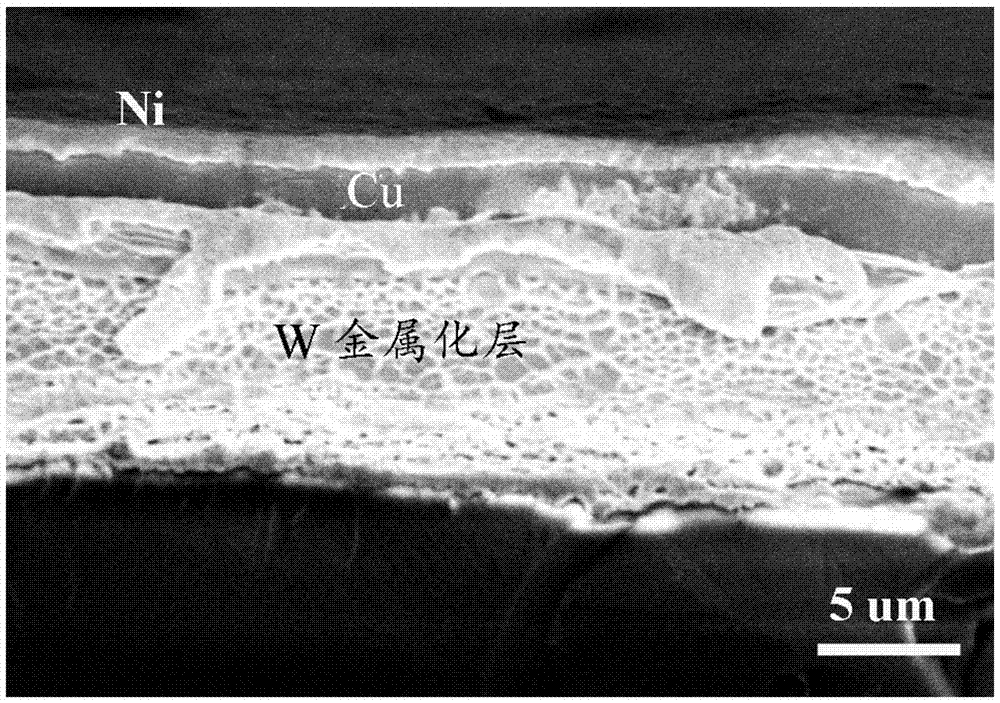

A method for secondary metallization and nickel plating on the surface of high temperature co-fired ceramics

A high-temperature co-fired ceramic and secondary metallization technology, applied in liquid chemical plating, metal material coating process, coating, etc. The effect of enhancing interfacial adhesion and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

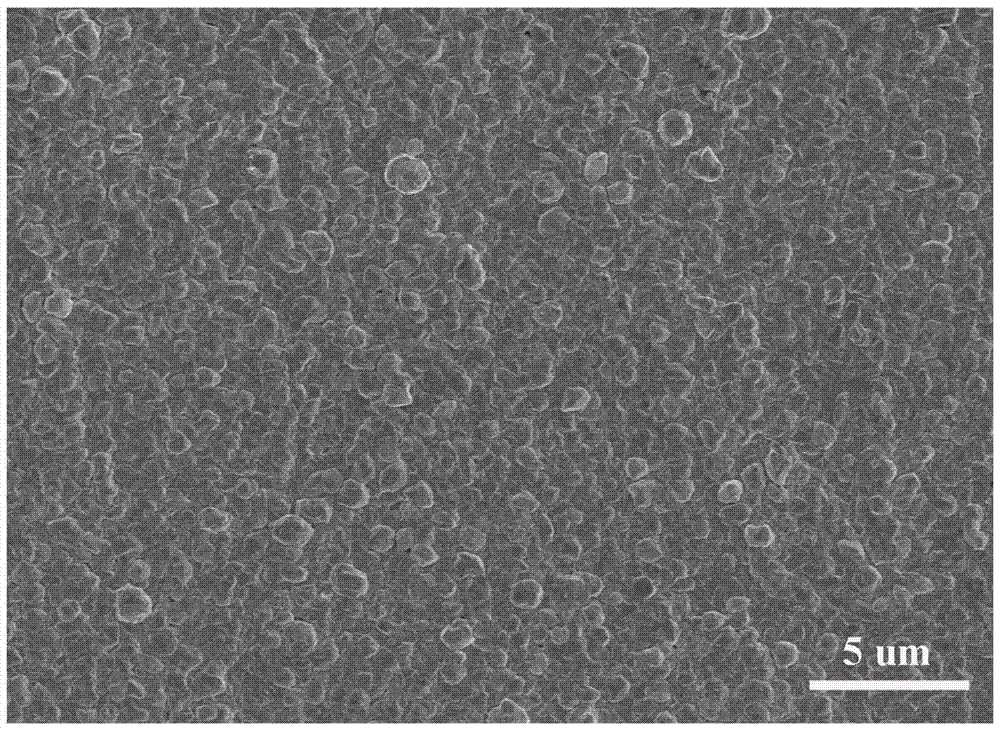

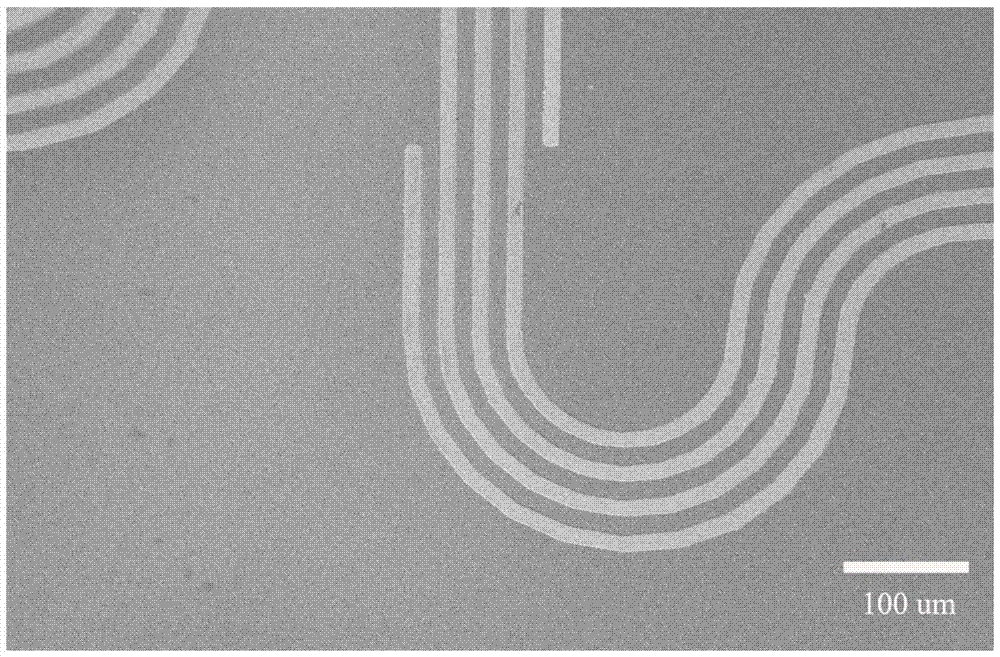

Method used

Image

Examples

Embodiment 1

[0036] The specific technical solutions are as follows:

[0037] (1) Alkaline degreasing

[0038] Soak the tungsten conductor test piece of the high temperature co-fired ceramic primary metallization in the degreasing solution at a temperature of 75 ℃ for 2 minutes, take it out and rinse it with water to obtain the degreasing test piece. The degreasing solution is composed of sodium hydroxide 85 g / L, sodium hydrogen phosphate 13 g / L, sodium bicarbonate 12 g / L, 1 g / L surfactant and deionized water, wherein the surfactant is 0.2 g / L sodium dioctyl sulfosuccinate, 0.8 g / L sodium glycocholate.

[0039] (2) Etching leveling

[0040]At room temperature, immerse the degreased test piece in the acid activation solution for 75 seconds, while slightly stirring the acid activation solution, take it out and rinse it with water to obtain an acid activation test piece; the acid activation solution consists of 24 mL / L mass percent 37.5 % concentrated hydrochloric acid, 15 mL / L hydrofluori...

Embodiment 2

[0055] The specific technical solutions are as follows:

[0056] (1) Alkaline degreasing

[0057] Soak the tungsten conductor test piece of the high temperature co-fired ceramic primary metallization in the degreasing solution at a temperature of 62 ℃ for 3.5 minutes, take it out and rinse it with water, and obtain the degreasing test piece. Wherein the degreasing solution is composed of 73 g / L sodium hydroxide, 14.5 g / L sodium hydrogen phosphate, 13.8 g / L sodium bicarbonate, 2.5 g / L surfactant and deionized water, wherein the surfactant It is 1.2 g / L sodium glycocholate and 1.3 g / L sodium dodecylsulfonate.

[0058] (2) Etching leveling

[0059] At room temperature, immerse the degreased test piece in the acid-activated solution for 60 seconds, while slightly stirring the acid-activated solution, take it out and rinse it with water to obtain an acid-activated test piece.

[0060] The acid activation solution was composed of 27.8 mL / L mass percentage of 37.5% concentrated hy...

Embodiment 3

[0074] The specific technical solutions are as follows:

[0075] (1) Alkaline degreasing

[0076] Soak a tungsten conductor test piece of high temperature co-fired ceramic primary metallization in a degreasing solution at a temperature of 70°C for 5 minutes, take it out and rinse it with water to obtain a degreasing test piece.

[0077] Wherein the degreasing solution is composed of sodium hydroxide 66 g / L, sodium hydrogen phosphate 17 g / L, sodium bicarbonate 15 g / L, 5 g / L surfactant and deionized water, wherein the surfactant It is 2 g / L sodium dodecyl sulfonate and 3 g / L sodium stearate.

[0078] (2) Etching leveling

[0079] At room temperature, immerse the degreased test piece in the acid-activated solution for 45 seconds, while stirring the acid-activated solution slightly, take it out and rinse it with water to obtain an acid-activated test piece.

[0080] The acid activation solution is composed of 32 mL / L mass percentage of 37.5% concentrated hydrochloric acid, 18 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com