Preparation method of hydrophilic ultra-filtration membrane

A hydrophilic and ultrafiltration membrane technology, applied in the field of membrane separation, can solve problems such as cumbersome operation, membrane loss, poor compatibility between inorganic materials and high molecular polymers, and achieve the effect of improving mechanical strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

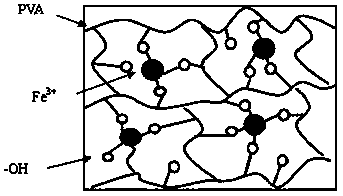

Method used

Image

Examples

Embodiment 1

[0038] Step 1, preparation of casting solution: by mass percentage, 18%PVDF, 3%PVA, 0.01%FeCl 3 , 3% LiCl and 76% solvent DMAc were stirred and dissolved at 90°C for 20 hours, and the casting solution was obtained after standing at 80°C for defoaming;

[0039] Step 2, preparation of nascent base film: Pour the casting solution prepared in step 1 onto a clean and flat glass plate at room temperature, and then scrape it with a stainless steel rod with 0.3mm copper wires tied at both ends to obtain the thickness 0.3mm nascent basement film;

[0040] Step 3, phase separation and curing treatment:

[0041] Pre-evaporate the nascent basement film for 5 seconds;

[0042] Then, under the condition of 30°C, put the nascent basement membrane into a hydrochloric acid aqueous solution with a pH of 2 and treat it in a gel bath for 0.5h to obtain a pre-cured nascent basement membrane;

[0043] Then, the pre-cured nascent base film is rinsed with water at room temperature to remove residu...

Embodiment 2

[0049] Different from Example 1, the mass proportion is 13%PVDF, 1%PVA, 3%TiCl 4 , 3% LiCl and 80% DMAc were mixed, the above mixture was placed at 90°C, stirred for 20h, and left to defoam at 80°C to obtain a uniform casting solution; at room temperature and relative humidity of 36%, the casting solution was placed in A nascent basement film with a thickness of 0.3mm is scraped on a flat glass plate, and the pre-evaporation time is 5 seconds. The gel phase is separated in a hydrochloric acid aqueous solution at 30°C and PH=2 and kept in a coagulation bath for 60 minutes, and then moved to clean water. Rinse repeatedly until the solvent is completely removed, soak in 30% glycerol aqueous solution for 12 hours, take it out and dry it naturally in the air to obtain a hydrophilic PVDF ultrafiltration membrane.

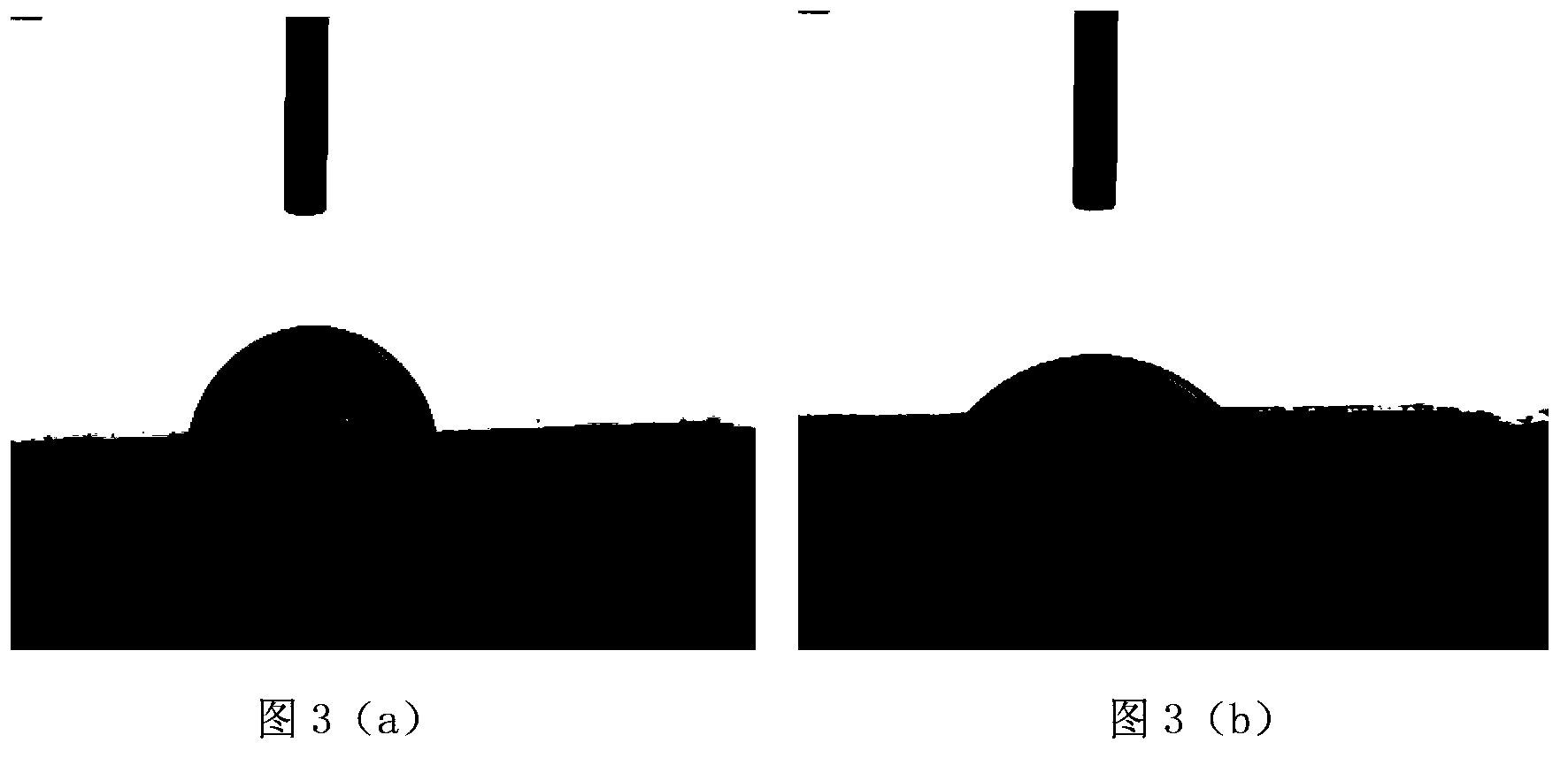

[0050] Under the conditions of 25°C and 0.1MPa, it is measured that the mechanical strength of the hydrophilic ultrafiltration membrane prepared in this example is 2.35-2...

Embodiment 3

[0053] Different from Example 1, the mass ratio is 14%PVDF, 15%PVP, 0.9%FeCl 3 , 3% LiCl was mixed with 67% solvent DMAc, the above mixture was placed at 60°C, stirred for 16 hours, and left to defoam at 80°C to obtain a homogeneous casting solution; at room temperature and relative humidity of 40%, the casting solution was Scrape a nascent base film with a thickness of 0.3mm on a flat glass plate, pre-evaporate for 10 seconds, immerse in 60°C, PH=2 hydrochloric acid aqueous solution for phase separation treatment for 120 minutes, move to clean water and rinse repeatedly until the solvent is completely removed , soaked in a 30% glycerol aqueous solution for 24 hours, took it out and dried it naturally in the air to obtain a hydrophilic PVDF ultrafiltration membrane.

[0054] At 25°C and 0.1 MPa, the water flux of the hydrophilic ultrafiltration membrane prepared in this example was measured to be 1035 L / m 2 h, the mechanical strength is 2.45MPa, the hydrophilic contact angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com