Paint pad dyeing afterfinish liquid and preparation method thereof

A post-finishing and coating technology, applied in the field of finishing liquid and preparation after pad dyeing of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

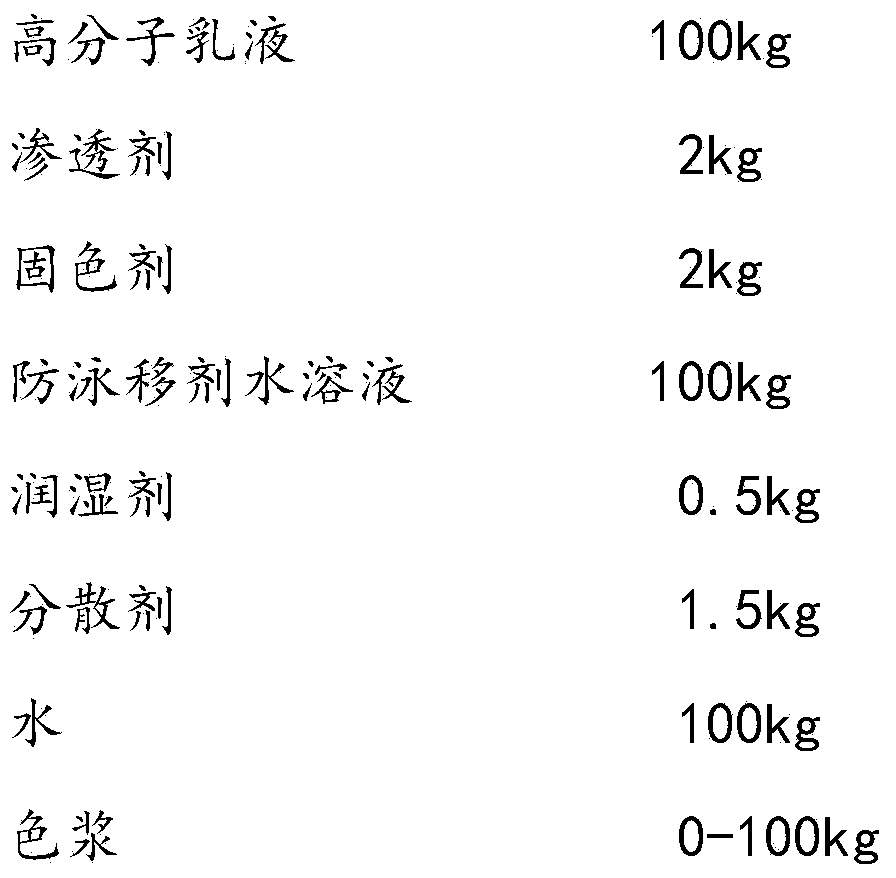

[0029] First add the color paste and dispersant evenly into the water, then add the polymer emulsion and other additives in turn, and stir evenly at room temperature for 15 minutes until the color and suspended matter in the solution are evenly distributed. Its components are as follows:

[0030]

[0031] Dip 3.0mm×450g / m2 polyester needle-punched non-woven fabric into the finishing solution, use plastic rollers to press and control the pressure at about 0.3Mpa, and the rolled base fabric with glue is heated and shaped after finishing. , the setting temperature is 140-180°C, and the setting time is 10 minutes.

Embodiment 2

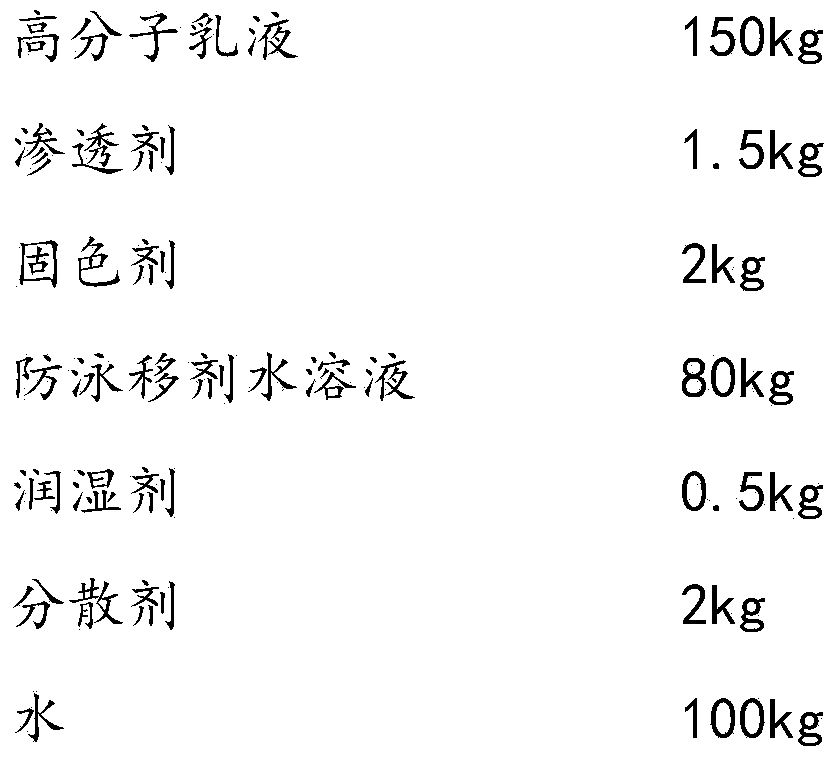

[0033] First add the color paste and dispersant evenly in the water, then add the polymer emulsion and other additives in turn, and stir evenly at room temperature for 15 minutes until the color and suspended matter in the solution are evenly distributed; its composition is as follows:

[0034]

[0035]

[0036] Dip 3.0mm×450g / m2 polyester needle-punched non-woven fabric into the finishing solution, use plastic rollers to press and control the pressure at about 0.3Mpa, and the rolled base fabric with glue is heated and shaped after finishing. , the setting temperature is 140-180°C, and the setting time is 10 minutes.

Embodiment 3

[0038] First add the color paste and dispersant evenly in the water, then add the polymer emulsion and other additives in turn, and stir evenly at room temperature for 15 minutes until the color and suspended matter in the solution are evenly distributed; its composition is as follows:

[0039]

[0040] Immerse the 4.0mm×520g / m2 polyester needle-punched nonwoven fabric in the finishing solution, use plastic rollers to press and control the pressure at about 0.3Mpa, and the rolled base fabric with glue is heated and shaped after finishing. , the setting temperature is 140-180°C, and the setting time is 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com