A kind of preparation method of environment-friendly zinc-aluminum-magnesium alloy coated steel plate

A technology of alloy coating, zinc-aluminum-magnesium, applied in metal material coating technology, coating, hot-dip coating technology, etc., can solve the problems of human body and environmental hazards, and achieve the goal of reducing hazards, uniform and dense coating structure, and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

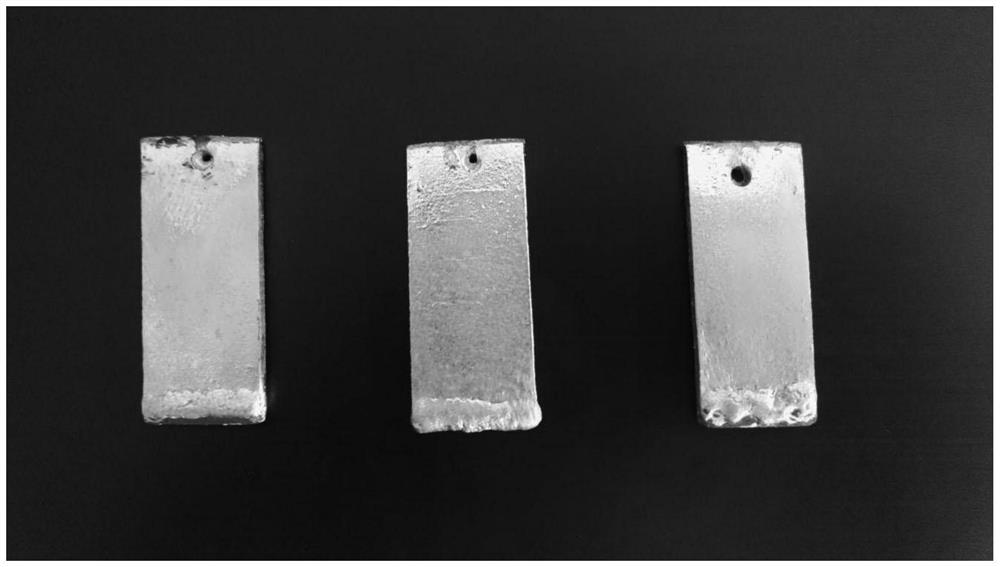

Embodiment 1

[0032] The invention discloses a preparation method of an environment-friendly zinc-aluminum-magnesium alloy coated steel plate.

[0033] Take zinc ingot, magnesium ingot, aluminum ingot and aluminum foil according to the ratio of Al: 6wt%, Mg: 3wt%, and the balance is Zn (the quality of aluminum foil is included in the content of aluminum). Heat the zinc to 500°C to completely melt, weigh the aluminum block, press the aluminum block into the molten zinc solution with a graphite rod until it is completely melted, and stir. Weigh the magnesium block, wrap it with aluminum foil, and press it into the molten zinc solution with a graphite rod until it is completely melted to reduce oxidation and ablation loss. Raise the temperature of the alloy solution to 560°C, stir once every 30 minutes, keep warm for 5 hours, and set aside.

[0034]Mechanical derusting: adopt continuous derusting machine to hot-rolled Q235 steel plate (the specific material of Q235 steel plate is C: 0.12~0.2w...

Embodiment 2

[0039] The invention discloses a preparation method of an environment-friendly zinc-aluminum-magnesium alloy coated steel plate.

[0040] Zinc ingots, magnesium ingots, aluminum ingots and aluminum foils are taken according to the ratio of Al: 6wt%, Mg: 3wt%, and the balance is Zn. Heat the zinc to 520°C to completely melt, weigh the aluminum block, press the aluminum block into the molten zinc solution with a graphite rod until it is completely melted, and stir. Weigh the magnesium block, wrap it with aluminum foil, and press it into the molten zinc solution with a graphite rod until it is completely melted to reduce oxidation and ablation loss. Raise the temperature of the alloy solution to 580°C, stir once every 30 minutes, keep warm for 8 hours, and set aside.

[0041] Mechanical descaling: The hot-rolled Q235 steel plate is polished and derusted by a continuous descaling machine to clean the surface rust of the steel plate and improve the production efficiency of subsequ...

Embodiment 3

[0046] The invention discloses a preparation method of an environment-friendly zinc-aluminum-magnesium alloy coated steel plate.

[0047] Zinc ingots, magnesium ingots, aluminum ingots and aluminum foils are taken according to the ratio of Al: 6wt%, Mg: 3wt%, and the balance is Zn. Heat the zinc to 520°C to completely melt, weigh the aluminum block, press the aluminum block into the molten zinc solution with a graphite rod until it is completely melted, and stir. Weigh the magnesium block, wrap it with aluminum foil, and press it into the molten zinc solution with a graphite rod until it is completely melted to reduce oxidation and ablation loss. Raise the temperature of the alloy solution to 560°C, stir once every 30 minutes, keep warm for 5 hours, and set aside.

[0048] Mechanical descaling: The hot-rolled Q235 steel plate is polished and derusted by a continuous descaling machine to clean the surface rust of the steel plate and improve the production efficiency of subsequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com