A kind of hot-dip galvanized aluminum-magnesium alloy coating and its preparation method and application

An aluminum-magnesium alloy, hot-dip galvanizing technology, applied in hot-dip plating process, metal material coating process, coating and other directions, to achieve the effect of reduced hot-dip plating temperature, controllable thickness and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

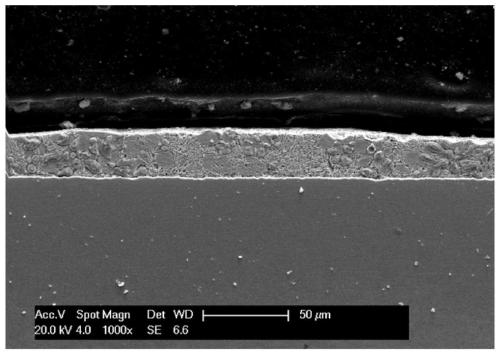

Image

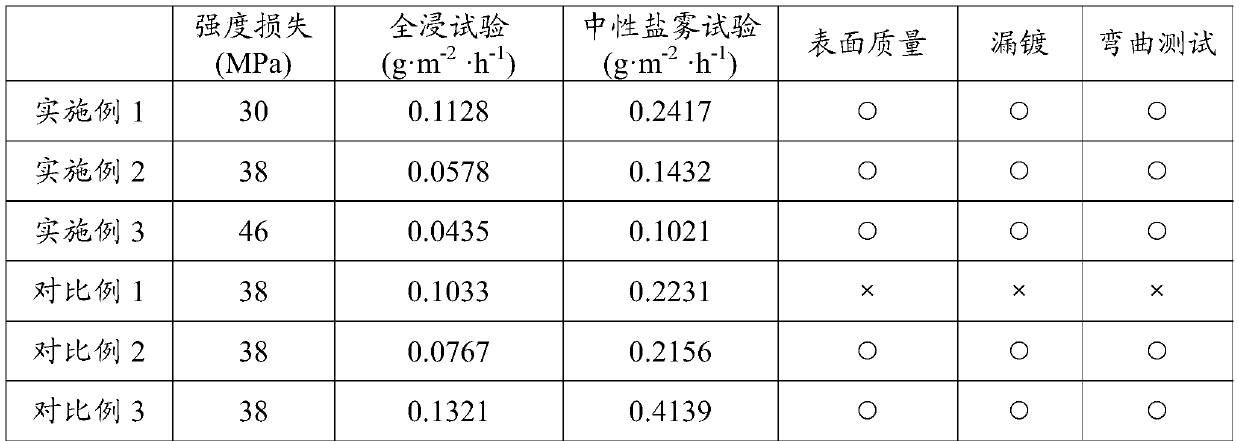

Examples

Embodiment 1

[0018] A hot-dip galvanized aluminum-magnesium alloy coating for a bridge cable steel wire, comprising the steps of:

[0019] (1) Place the sample steel wire obtained after drawing at a temperature of 70°C and a mass concentration of 15% NaOH solution for degreasing treatment, and after washing with water, place it at a temperature of 70°C and a mass concentration of 15% HCl solution for removal Rust treated, blow dry.

[0020] (2) the sample steel wire of step (1) gained is placed in chemical composition mass fraction ratio and is ZnCl 2 :NH 4 Cl:SnCl 2 :KCl:Na 3 AlF 6 :CeCl 3 :H 2 In the fluxing solution of O=50:50:40:1:1:1:857, the fluxing time was 120s, and the fluxing temperature was 70°C.

[0021] (3) drying the sample obtained in step (2) at 100°C;

[0022] (4) Place the sample steel wire treated in step (3) in the zinc-aluminum-magnesium alloy solution whose chemical composition mass percentage is Zn:Al:Mg:Ce=98.49:1:0.5:0.01, dip-plating for 30s, The hot-dip ...

Embodiment 2

[0026] A hot-dip galvanized aluminum-magnesium alloy coating for a bridge cable steel wire, comprising the steps of:

[0027] (1) Place the sample steel wire obtained after drawing at a temperature of 70°C and a mass concentration of 15% NaOH solution for degreasing treatment, and after washing with water, place it at a temperature of 70°C and a mass concentration of 15% HCl solution for removal Rust treated, blow dry.

[0028] (2) the sample steel wire of step (1) gained is placed in chemical composition mass fraction ratio and is ZnCl 2 :NH 4 Cl:SnCl 2 :KCl:Na 3 AlF 6 :CeCl 3 :H 2 In the fluxing solution of O=100:95:80:15:10:5:695, the fluxing solution was 90s, and the fluxing temperature was 70°C.

[0029] (3) drying the sample obtained in step (2) at 100°C;

[0030] (4) Place the sample steel wire treated in step (3) in the zinc-aluminum-magnesium alloy solution whose chemical composition mass percentage is Zn:Al:Mg:Ce=93.3:5:1.5:0.2, dip-plating for 90s, The hot-...

Embodiment 3

[0034] A hot-dip galvanized aluminum-magnesium alloy coating for a bridge cable steel wire, comprising the steps of:

[0035] (1) Place the sample steel wire obtained after drawing at a temperature of 70°C and a mass concentration of 15% NaOH solution for degreasing treatment, and after washing with water, place it at a temperature of 70°C and a mass concentration of 15% HCl solution for removal Rust treated, blow dry.

[0036] (2) the sample steel wire of step (1) gained is placed in chemical composition mass fraction ratio and is ZnCl 2 :NH 4 Cl:SnCl 2 :KCl:Na 3 AlF 6 :CeCl 3 :H 2 In the fluxing solution of O=200:150:160:30:20:10:430, the fluxing temperature was 70° C. for 60 seconds.

[0037] (3) drying the sample obtained in step (2) at 100°C;

[0038] (4) Place the sample steel wire treated in step (3) in the zinc-aluminum-magnesium alloy solution whose chemical composition mass percentage is Zn:Al:Mg:Ce=86.5:10:3:0.5, dip-plating for 180s, The hot-dip temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com