A high-corrosion-resistant single-coated zinc-aluminum-magnesium rare earth protective coating and its preparation process

A preparation process, zinc-aluminum-magnesium technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of uneven coating surface, inability to form high-performance infiltration layer, and high process requirements, and achieve resistance to Excellent corrosion performance, overcoming difficulties in flux plating, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

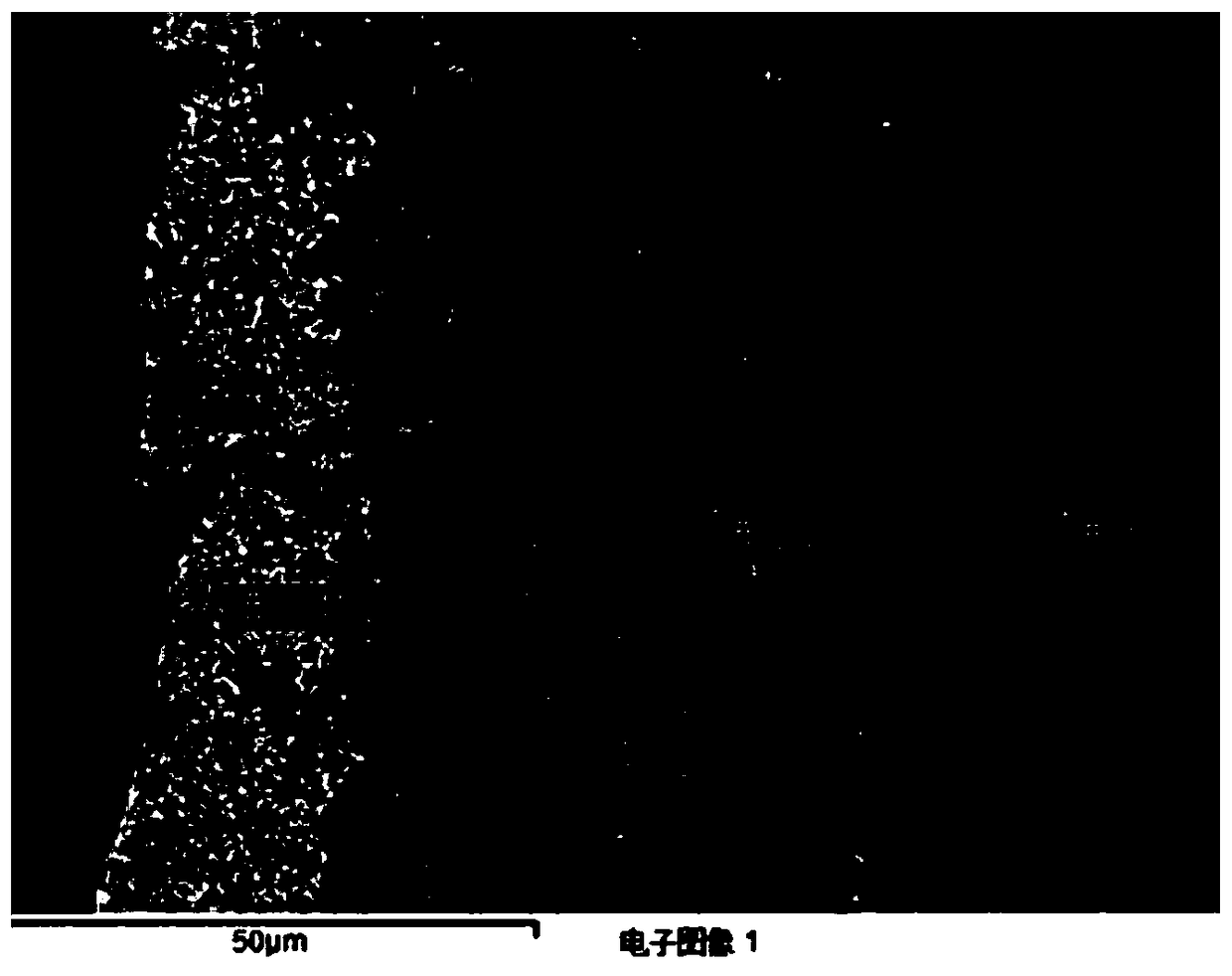

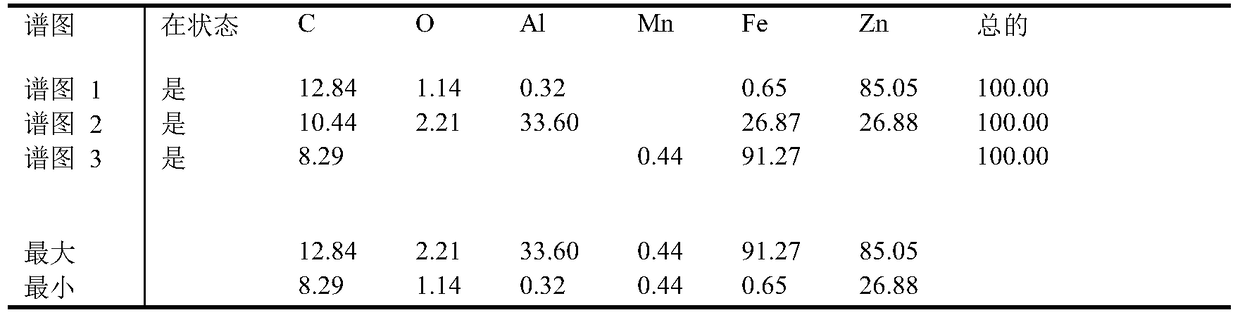

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of highly corrosion-resistant single-plated zinc-aluminum-magnesium rare earth protective coating comprises the steps of:

[0031] 1) Decontaminate the dirt on the surface of the metal material, wash the metal material 3 times with NaOH solution and clear water at 85°C, and remove the grease on the surface of the metal material;

[0032] 2) Carry out grinding and derusting treatment on the metal material after the treatment in step 1), and the derusting level is not lower than Sa2 1 / 2 class;

[0033] 3) The single-plating flux is ZnCl 2 30%; NaF 1%; KHF 2 5%; PCl 3 0.5%; SnCl 2 2%; BeCl 2 1%; SiO 2 0.5%; ZnMnO 4 0.05%; composite surfactant 1%, the rest is water, of which ZnMnO 4 The function is to form hydrates with other components to promote the hot-dip plating process; the composite surfactant is a compound of alkyl sulfonate, fatty alcohol ether phosphate, and N-alkyl aminodipropionic acid. and step 2) place the treated metal material i...

Embodiment 2

[0038] Embodiment 2: A kind of highly corrosion-resistant single-plated zinc-aluminum-magnesium rare earth protective coating comprises the following steps:

[0039] 1) Decontaminate the dirt on the surface of the metal material, wash the metal material 3 times with NaOH solution and clear water at 80°C, and remove the grease on the surface of the metal material;

[0040] 2) Carry out grinding and derusting treatment on the metal material after the treatment in step 1), and the derusting level is not lower than Sa2 1 / 2 class;

[0041] 3) The single-plating flux is ZnCl 2 35%; NaF 2%; KHF 2 6.5%; PCl 3 0.75%; SnCl 2 2.5%; BeCl 2 1.2%; SiO 2 1%; ZnMnO 4 0.075%; composite surfactant 1%, the rest is water, of which ZnMnO 4 The function is to form hydrates with other components to promote the hot-dip plating process; the composite surfactant is a compound of alkyl sulfonate, fatty alcohol ether phosphate, and N-alkylaminodipropionic acid. and step 2) place the treated metal ...

Embodiment 3

[0046] Embodiment 3: A kind of highly corrosion-resistant single-plated zinc-aluminum-magnesium rare earth protective coating comprises the steps of:

[0047] 1) Decontaminate the dirt on the surface of the metal material, wash the metal material 3 times with NaOH solution and clear water at 85°C, and remove the grease on the surface of the metal material;

[0048] 2) Carry out grinding and derusting treatment on the metal material after the treatment in step 1), and the derusting level is not lower than Sa2 1 / 2 class;

[0049] 3) The single-plating flux is ZnCl 2 40%; NaF 3%; KHF 2 8%; PCl 3 1.0%; SnCl 2 3%; BeCl 2 1.5%; SiO 2 1.5%; ZnMnO 4 0.1%; composite surfactant 1%, the rest is water, of which ZnMnO 4 The function is to form hydrates with other components to promote the hot-dip plating process; the composite surfactant is a compound of alkyl sulfonate, fatty alcohol ether phosphate, and N-alkylaminodipropionic acid. and step 2) place the treated metal material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com