Equipment and technology of dual-cathode plasma deposition nano-coating on diamond surface

A plasma deposition and nano-coating technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of small single plating amount, high deposition temperature, decreased diamond strength, etc. Effects of sintering time, deposition efficiency improvement, and bond strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

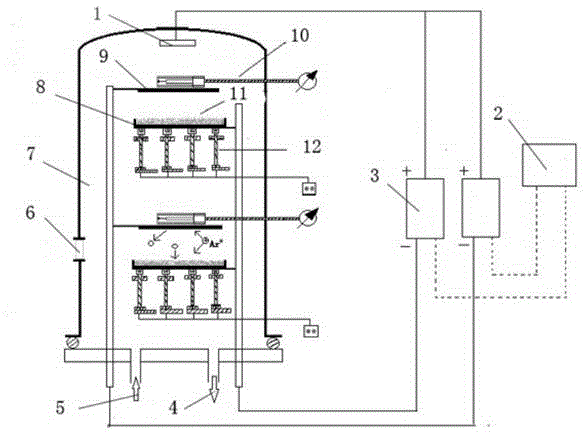

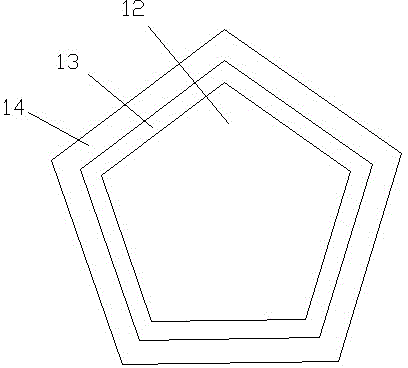

[0037] A kind of equipment for double-cathode plasma deposition nano-coating on the surface of diamond, which is used to prepare nano-metal coating on the surface of diamond (artificial or natural) particles or powder. The equipment includes a power supply 3 and a vacuum chamber 7, which is located inside the vacuum chamber 7 The target material device 9, the material tray 8, the ultrasonic vibration concentrator 12, the thermocouple 10, the air inlet 5 and the gas outlet 4 located at the bottom of the vacuum chamber 7, argon enters the vacuum chamber 7 through the air inlet 5, and the vacuum The side wall of the chamber 7 is also provided with an observation port 6 for observing the internal conditions of the vacuum chamber. In the vacuum chamber, the tray 8 is arranged on one side of the target 11, and the anode plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com