Novel and efficient structural part hot dip Galfan promotion flux and preparation method and application thereof

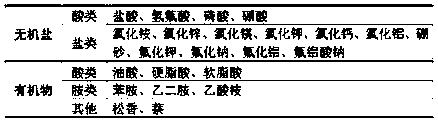

A technology of plating flux and structural parts, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of poor uniformity of coating thickness, poor coating brightness, and many zinc bumps, etc., to achieve improved wetting Ability, stable composition, effect of suppressing smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] A kind of preparation method of hot-dip Galfan plating flux of novel high-efficiency structure part, comprises the following steps:

[0072] (i) Preparation of alcohol solution

[0073] Weigh a certain amount of rare earth chloride and alcohols in proportion and mix them to form an alcohol solution;

[0074] (ii) Preparation of aqueous solution

[0075] Weigh a certain amount of ammonium chloride in proportion, add a certain amount of water to dissolve it; weigh a certain quality of zinc chloride, add it to the ammonium chloride solution under stirring conditions, and add the remaining required Water, configured as an aqueous solution;

[0076] (iii) Preparation of plating flux

[0077] The alcohol solution obtained in the step (i) is slowly poured into the aqueous solution obtained in the step (ii) under stirring condition, and a new type of high-efficiency structural part hot-plated Galfan flux is obtained.

[0078] Application of a new type of high-efficiency hot...

Embodiment 1

[0081] A kind of preparation method of hot-dip Galfan plating flux of novel high-efficiency structure part, comprises the following steps:

[0082] (i) Preparation of alcohol solution

[0083] Weigh 1kg of rare earth chloride and 11kg of ethanol to mix and configure alcohol solution;

[0084] (ii) Preparation of aqueous solution

[0085] Weigh 10kg of ammonium chloride, add a certain amount of water to dissolve it; weigh 50kg of zinc chloride, add it to the ammonium chloride solution while stirring, and add the remaining required water to form an aqueous solution; The total amount of water added is 28kg;

[0086] (iii) Preparation of plating flux

[0087] The alcohol solution obtained in the step (i) is slowly poured into the aqueous solution obtained in the step (ii) under stirring condition, and a new type of high-efficiency structural part hot-plated Galfan flux is obtained.

[0088] Application of a new type of high-efficiency hot-dip Galfan flux for structural parts, ...

Embodiment 2

[0090] A kind of preparation method of hot-dip Galfan plating flux of novel high-efficiency structure part, comprises the following steps:

[0091] (i) Preparation of alcohol solution

[0092] Weigh 0.1kg of rare earth chloride and 3kg of propanol and mix to form an alcoholic solution;

[0093] (ii) Preparation of aqueous solution

[0094] Weigh 2kg of ammonium chloride, add a certain amount of water to dissolve it; weigh 40kg of zinc chloride, add it to the ammonium chloride solution under stirring, and add the remaining required water to form an aqueous solution; The total addition of water is 54.9kg;

[0095] (iii) Preparation of plating flux

[0096] The alcohol solution obtained in the step (i) is slowly poured into the aqueous solution obtained in the step (ii) under stirring condition, and a new type of high-efficiency structural part hot-plated Galfan flux is obtained.

[0097] Application of a new type of high-efficiency hot-dip Galfan flux for structural parts, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com