Environment-friendly rust removing and resisting agent applied to acid pickling

A technology of pickling rust removal and antirust agent, which is applied in the field of pickling rust removal and antirust agent on the surface of iron and steel products. It can solve the problems of long time for rust removal, high toxicity of chromic anhydride, and irritating odor, so as to reduce labor productivity , The production process is simple and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

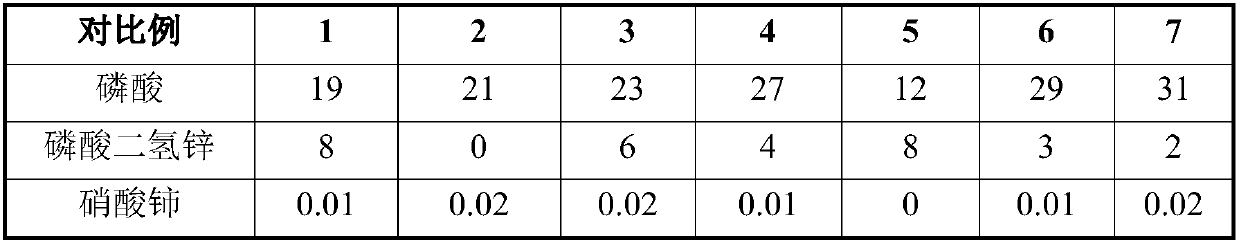

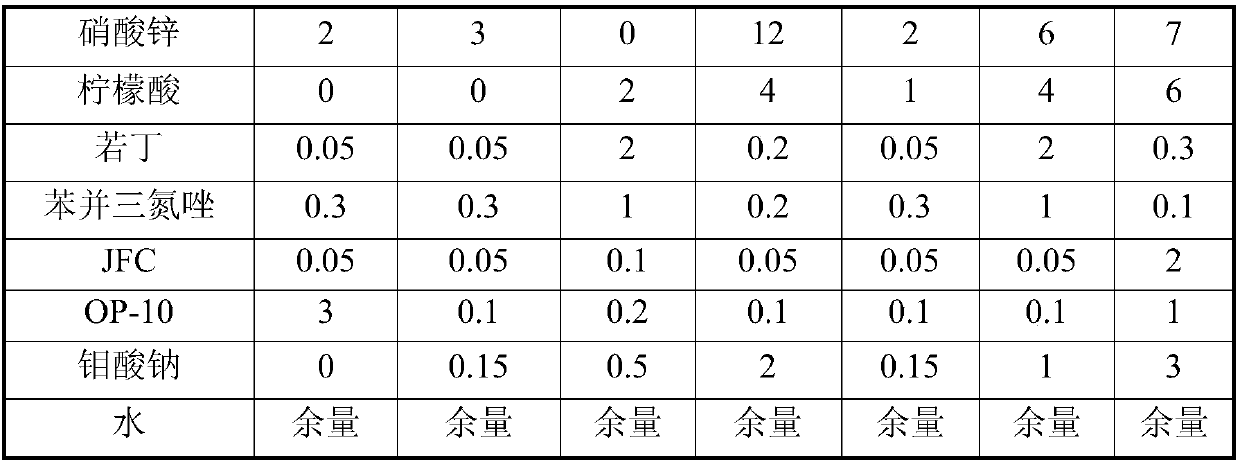

[0032] The preparation process of the rust-removing and anti-rust agent of the present invention is: firstly weigh each raw material according to the above-mentioned proportion, then put the corrosion inhibitor and the surfactant into an appropriate amount of warm water (50-60° C.) and stir to make them fully dissolve, (Because corrosion inhibitor and tensio-active agent are difficult to dissolve in cold water) then add remaining water, complexing agent, passivating agent, oxidizing agent, zinc dihydrogen phosphate, phosphoric acid in turn, fully mix, promptly obtain the derusting of the present application Rust inhibitor.

[0033] Immerse the sample to be treated in the above-mentioned rust-removing and anti-rust agent for 15-25 minutes at room temperature and 10 minutes at 40-50°C to achieve the rust-removing and anti-rust effect.

[0034] The rust remover and antirust agent of the present invention is compounded by phosphoric acid, zinc dihydrogen phosphate, oxidizing agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com