Patents

Literature

30results about How to "Production and use safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

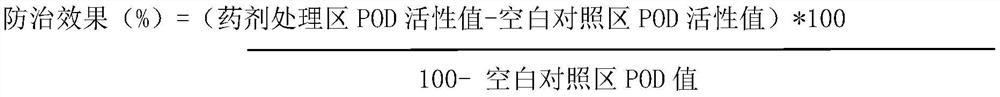

Organic selenium-enriched liquid fertilizer and preparation method thereof

ActiveCN101817710AProduction and use safetyImprove absorption efficiencyFertilizer mixturesTrace elementBoron

The invention discloses an organic selenium-enriched liquid fertilizer and a preparation method thereof. The organic selenium-enriched liquid fertilizer comprises the following components in percentage by weight: more than or equal to 10 percent of total animal keratin hydrolyzed amino acid, 0.1 to 3 percent of organic selenium in terms of selenium, 2 to 3 percent of surfactant, more than or equal to 1.0 percent of trace element zinc required by plants, more than or equal to 1.0 percent of boron, and the balance of water. The invention also provides the preparation method of the organic selenium-enriched liquid fertilizer. The organic selenium-enriched liquid fertilizer is safe in production and application, can improve the selenium absorption efficiency of farm crops and improve disease and insect resisting, drought and flood resisting and yield increasing capacities of the farm crops, has the characteristics of supplementing the selenium, improving the fruit quality of the farm crops and reducing heavy metal toxicity, and has a storage life of 3 years without deterioration.

Owner:成都华宏生物科技有限公司

Ultralow-temperature glass antifogging anti-frosting antifreeze agent

InactiveCN101659854AHigh transparencyGood anti-fog performanceOther chemical processesChemistryIsopropylene glycol

The invention provides a formulation and a manufacturing technique for an ultralow-temperature glass antifogging anti-frosting antifreeze agent. The formulation is characterized by comprising the following components (in percentage by weight): 1, 100 percent of Tween-80; 2, 100 percent of isopropanol; 3, 5 percent of propylene glycol; 4, 10 percent of 10 percent lauryl sodium sulfate; 5, 8 percentof mono-butyl ether; 6, 8 percent of diethylene glycol; and 7, 40 percent of water. The manufacturing technique comprises the following steps: adding materials 1 and 2 to a container and mixing the two well; adding a material 3 and evenly mixing to obtain liquid A; slowly adding a material 4 to the liquid A and stirring while adding to obtain liquid B; sequentially adding materials 5, 6 and 7 tothe liquid B, namely adding one material, evenly stirring and then adding the next one; mixing the obtained product well through fast stir; and adding 40 percent of water, diluting and evenly mixing to obtain a finished product. The product which is aqueous solution has the advantages of no toxicity, no pollution, low cost, use convenience, good antifogging anti-frosting effects, capability of notfreezing at 85 DEG C below zero and good antifogging effects at 50 DEG C below zero.

Owner:BEIJING YUJIAMING TRI STATE ION RES INST

Environment-friendly beta-cypermethrin emulsion in water and preparing method thereof

InactiveCN104920443AGood environmental compatibilityPromote decompositionBiocideAnimal repellantsCypermethrinEmulsion

Environment-friendly beta-cypermethrin emulsion in water is composed of, by mass, 2-10% of beta-cypermethrin, 5-25% of plant source solvent, 2-10% of surface active agent, 1-5% of cosurfactant, 0.1-1% of dispersion stabilizer, 0.05-0.5% of pH modifier, and the balance water. The environment-friendly beta-cypermethrin emulsion in water has the advantages of being stable, environmentally friendly and efficient.

Owner:CHINA RES INST OF DAILY CHEM IND

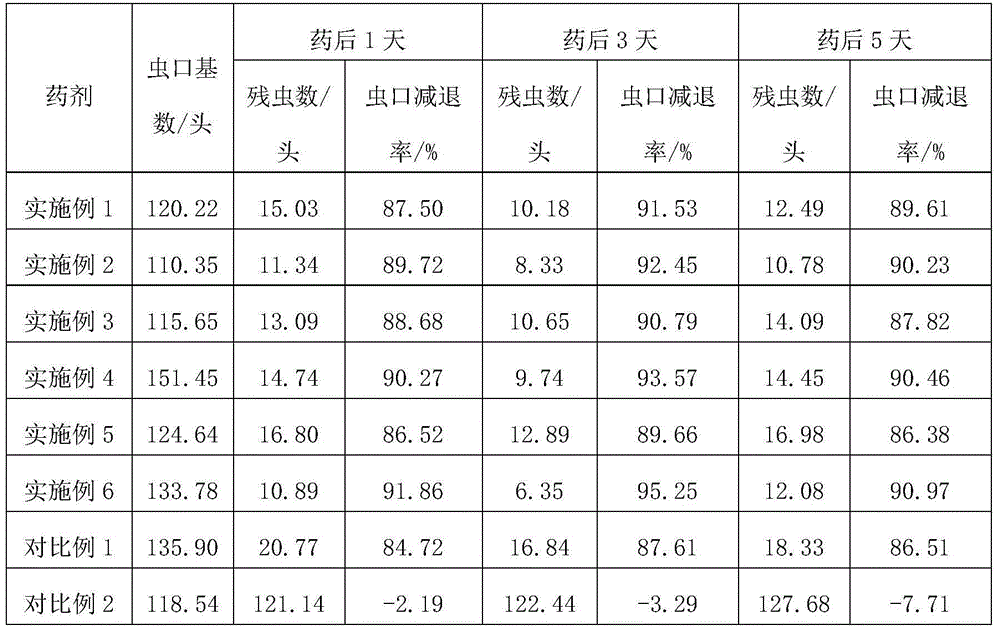

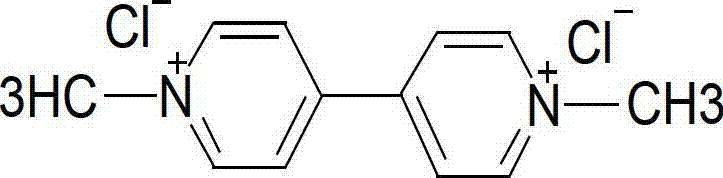

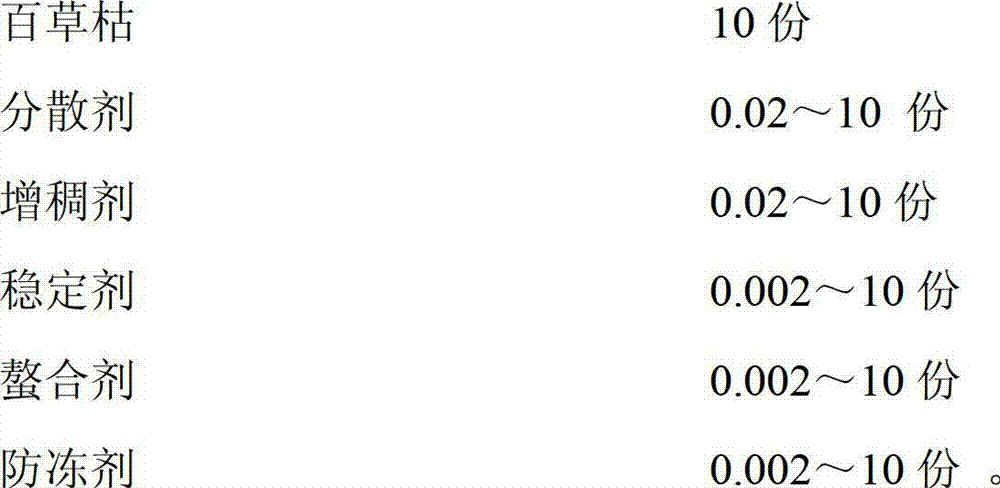

Paraquat cream and its preparation technology

InactiveCN103070173ASimple production processEasy to manufactureBiocideAnimal repellantsParaquatAnti freezing

The invention belongs to the organic pesticide field, and discloses a paraquat cream and its preparation technology. The paraquat cream comprises the following substances, by mass, 10 parts of paraquat, 0.02-10 parts of a dispersant, 0.02-10 parts of a thickening agent, 0.002-10 parts of a stabilizing agent, 0.002-10 parts of a chelating agent, and 0.002-10 parts of an anti-freezing agent. The preparation technology comprises the following steps: uniformly mixing the dispersant, the thickening agent, the stabilizing agent, a pH adjusting agent and water, adding a paraquat mother liquor, stirring for emulsification, discharging, and cooling to obtain the paraquat cream. The paraquat cream has the advantages of high flash point, difficult combustion and explosion, safe production and use, environmental protection, low cost, strong market competitiveness, easy packaging, and excellent weeding effect.

Owner:SHANGHAI NORMAL UNIVERSITY

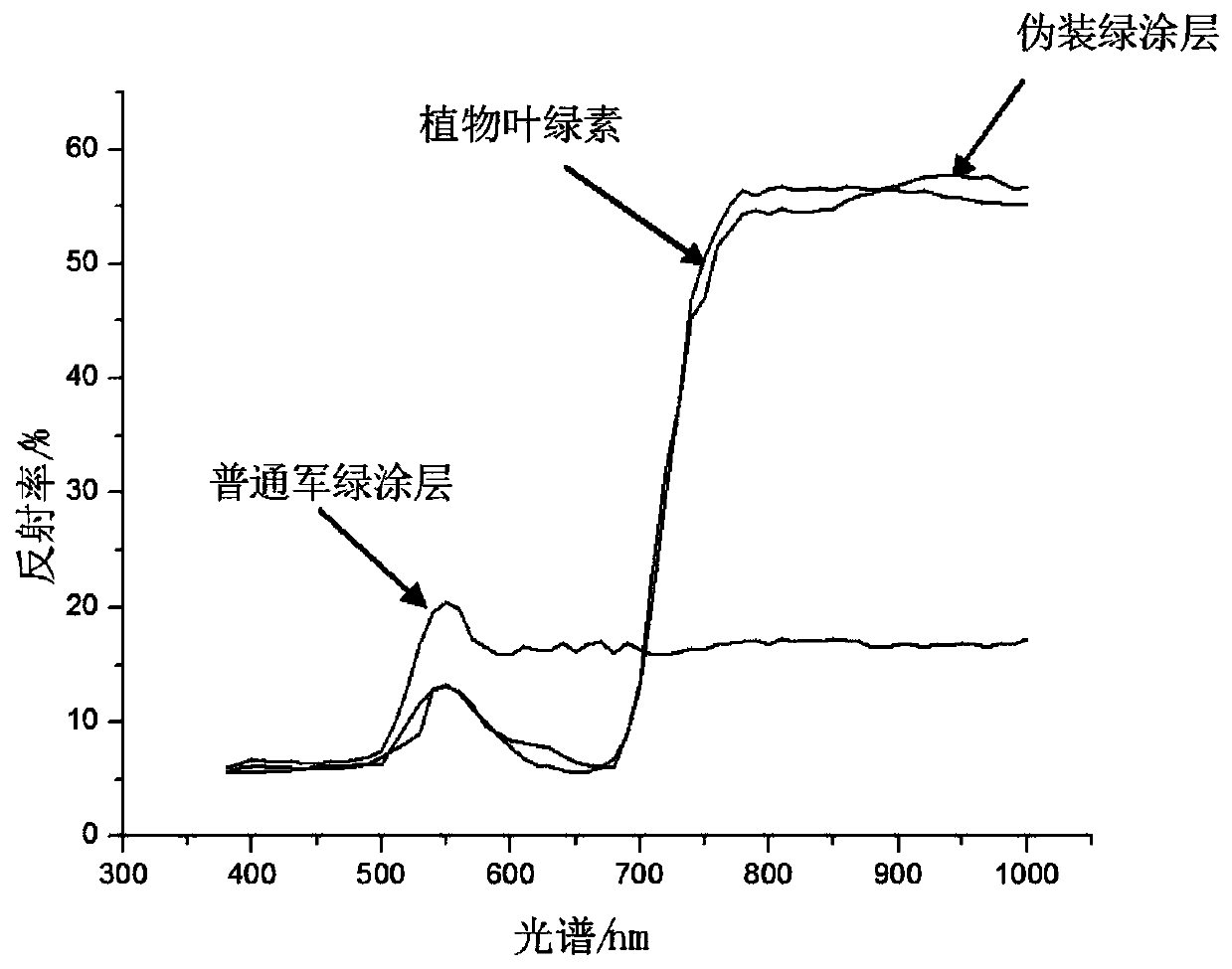

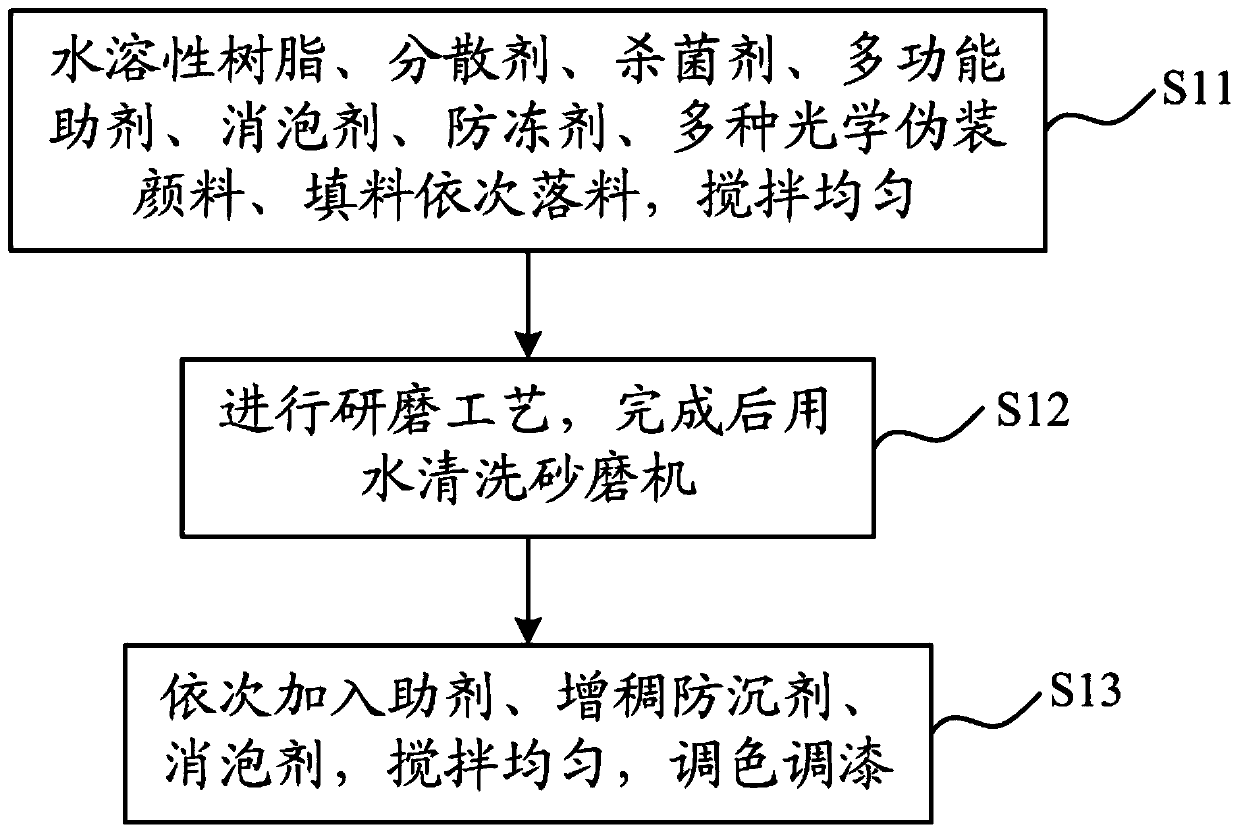

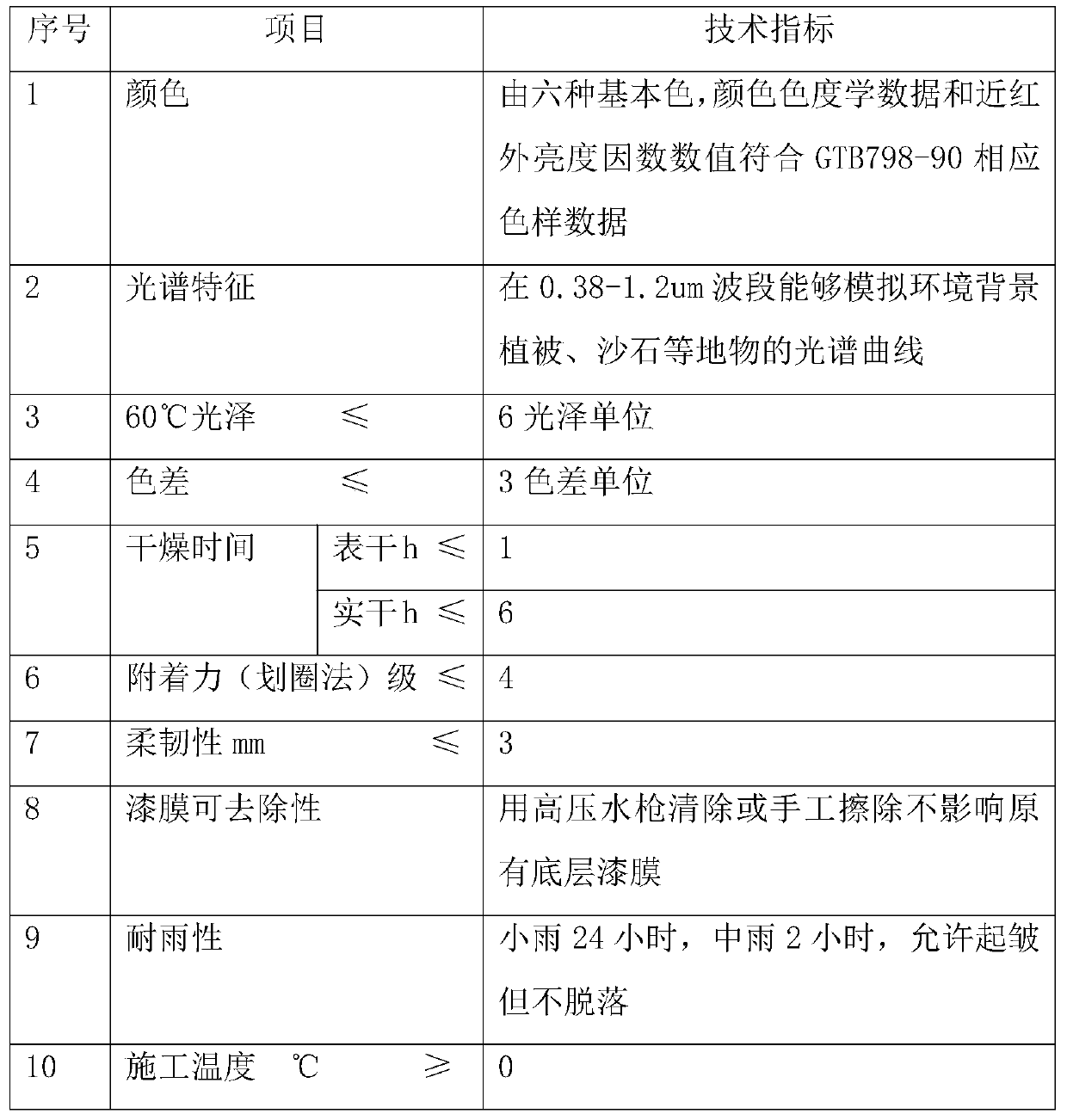

Water-soluble temporary camouflage coating and preparation method thereof

The invention discloses a water-soluble temporary camouflage coating and a preparation method thereof, and belongs to the technical field of camouflage coatings. A system in which water-soluble resinis compounded with acrylic emulsion serves as a base stock, multiple optical camouflage pigments and various assistants are added, mechanical dispersing, grinding and paint mixing are carried out, andthe water-soluble temporary camouflage coating is obtained. The water-soluble resin provides film forming performance for a coating, further has hydrophilic performance and swells after encounteringwater, the coating swells when the coating is cleaned by a high-pressure water gun in the later period, adhesive force is lost under high-speed currents, and disengagement happens. The adhesive performance of the film-formed acrylic emulsion is good, short-time rainwater can be resisted, balance is achieved after the water-soluble resin and the acrylic emulsion are mixed according to a certain ratio, the problems about coating adhesion in the earlier period and coating removability in the later period are solved, and the requirements of temporary coating are met. By changing the pigments in the formula, the water-soluble temporary camouflage coating can be prepared into a dark green coating, a yellow green coating, a sandy soil coating, a lime earth coating and other coatings with different colors, and can meet the requirements of camouflage coating with various geographical characteristics.

Owner:江苏新创天利新材料发展有限公司

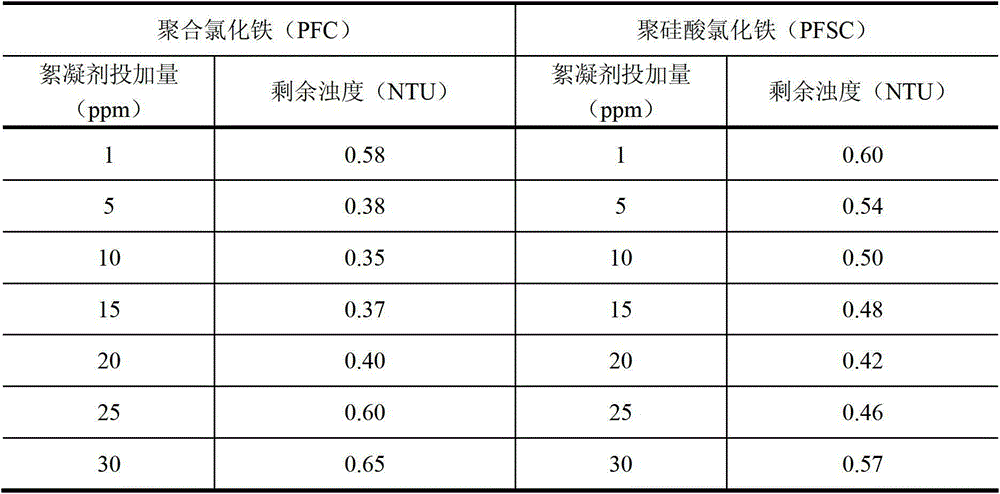

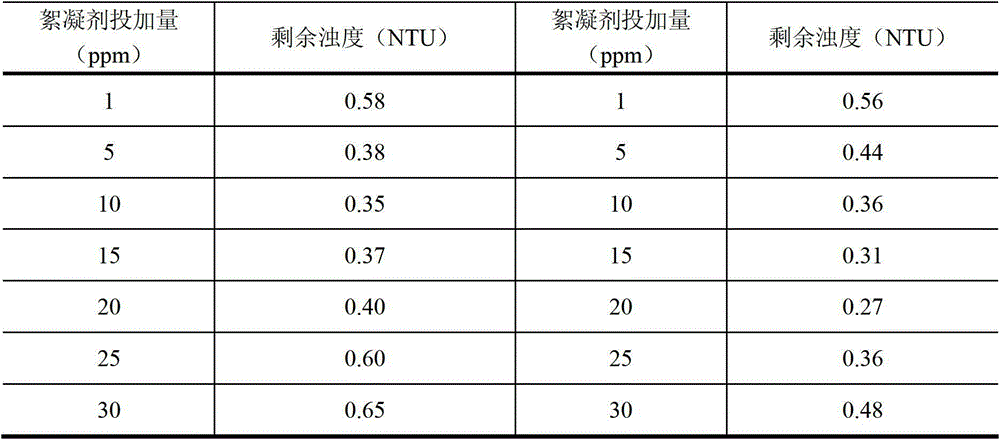

Preparation method of polysilicate ferric chloride flocculant

InactiveCN102910717ASimple production processProduction and use safetyWater/sewage treatment by flocculation/precipitationSODIUM SILICATE SOLNFerric

The invention discloses a preparation method of polysilicate ferric chloride flocculant. The method is characterized by comprising the following steps: firstly, the preparation of polyferric chloride: adding industrial hydrochloric acid into ground hematite to be conducted to oxidation reaction at 75 to 95 DEG C, performing filtering, obtaining ferric trichloride solution, adjusting the pH value of the ferric trichloride solution to be 1.2 to 1.6, performing aging, and then obtaining polyferric chloride solution; secondly, the preparation of polysilicic acid: gradually adding dilute sulphuric acid into sodium silicate solution, adjusting the pH value to be 1.8 to 2.2, performing activating, and then obtaining polysilicic acid solution; and thirdly, the preparation of polysilicate ferric chloride: mixing the polyferric chloride solution and the polysilicic acid according to the quantity relative ratio of iron to silicon being 1:1, adjusting the pH value of the mixed solution to be 1.8 to 2.2 at 38 to 42 DEG C, performing seasoning, and then obtaining polysilicate ferric chloride solution. The flocculant has the advantages that raw material is easily available, the processes are simple, the cost is low, the flocculant is safe to produce and use, and the effect is excellent.

Owner:HUBEI GETRAIN CHEM TECH

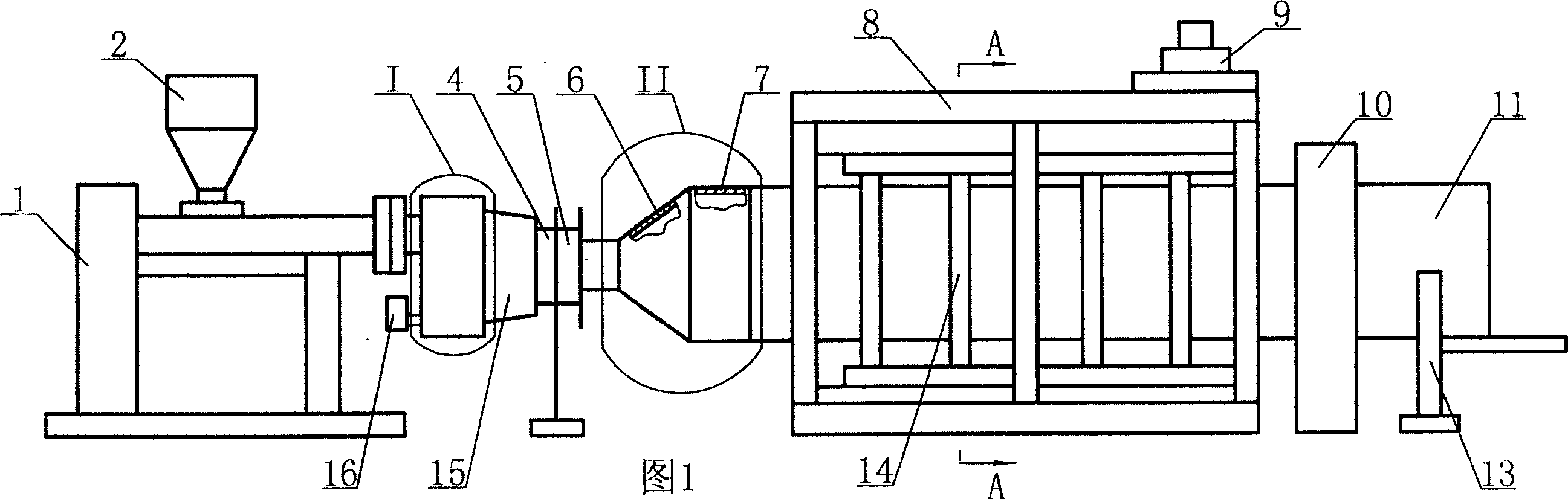

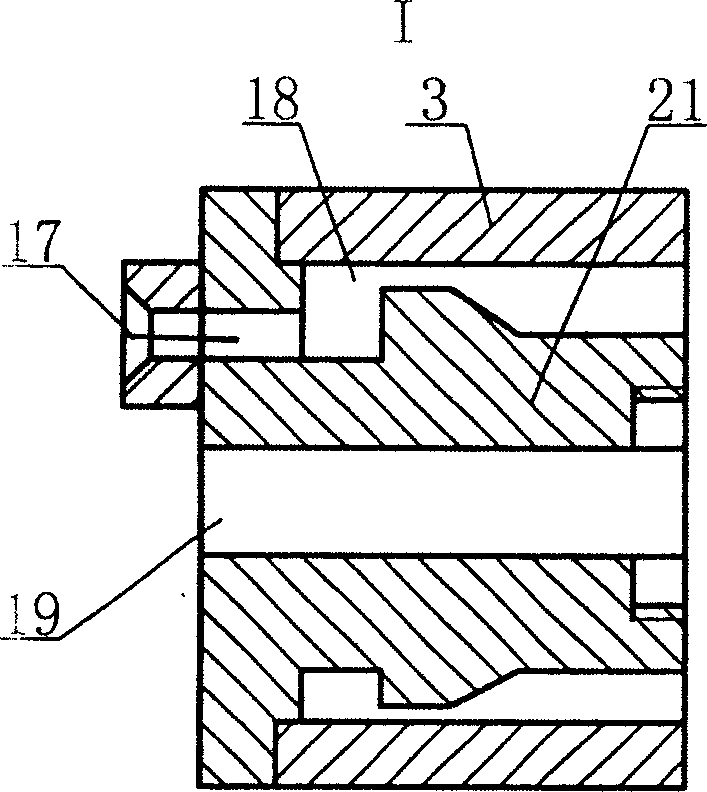

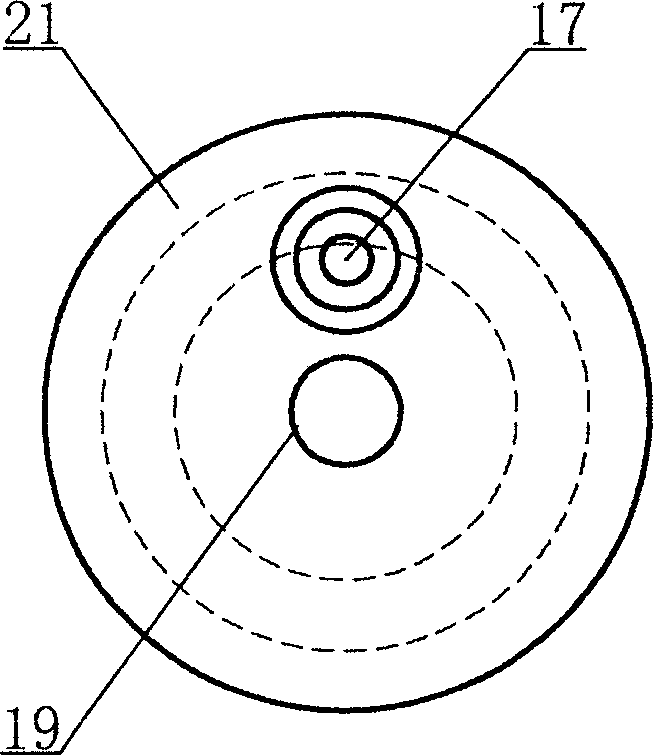

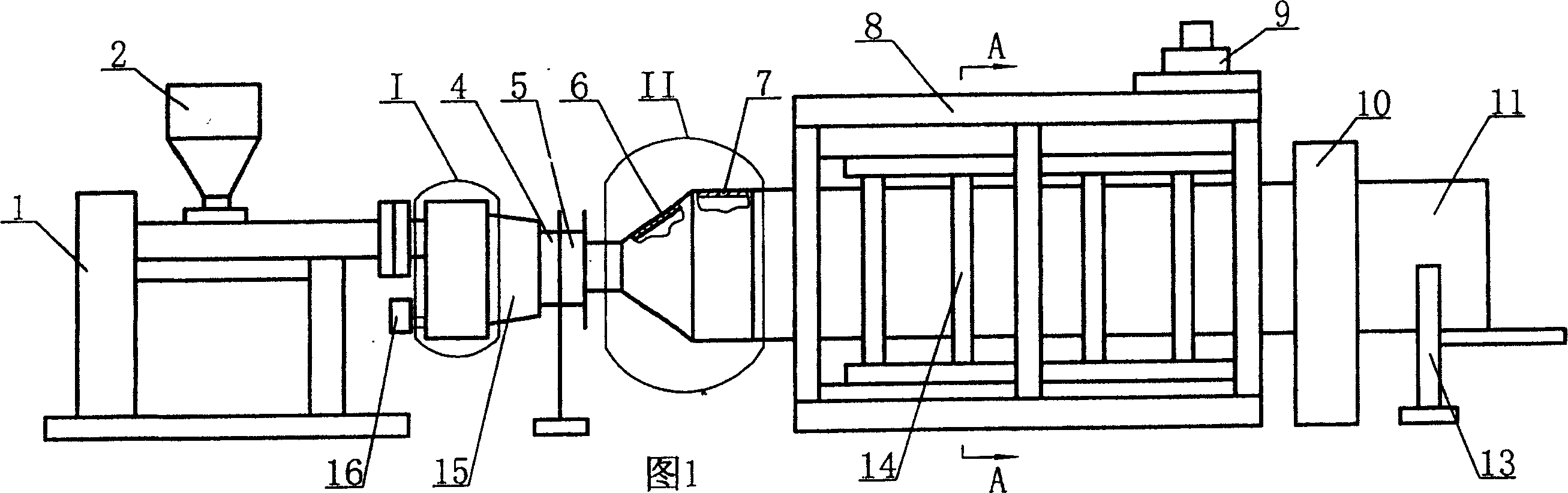

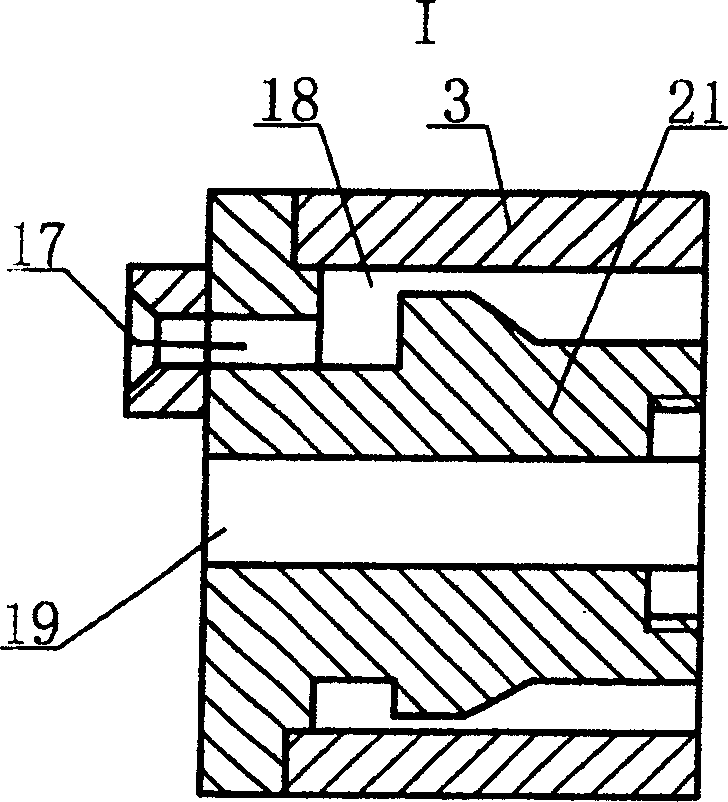

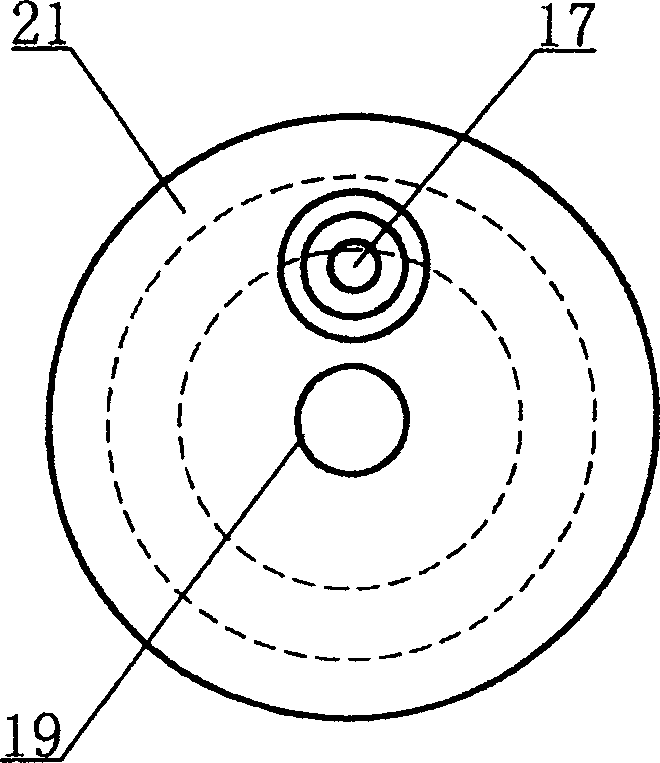

Reinforced polyethylene pipe with super high molecular weight, manufacturing method and apparatus thereof

InactiveCN1584383AReduce manufacturing costLow fatigue resistanceRigid pipesTubular articlesHigh intensityUltimate tensile strength

This invention relates to method and apparatus for production of enhanced PVC pipes of super-high molecular weight. Their performance is as below: pull resistance of 50MPa or so, reduced wall thickness by 60 - 75% of PE100 pipe or 70 - 85% of PVC pipe of super-high molecular weight, impact resistance of 130KJ / M2, wear resistance as 4 - 7 times of steel, environmental stress resistance more than 4000 hours, fatigue resistance over 800,000 times, and highest impact resistance at -40deg.C. Costs on production are reduced by 35%, with easy installation and low cost on engineering.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

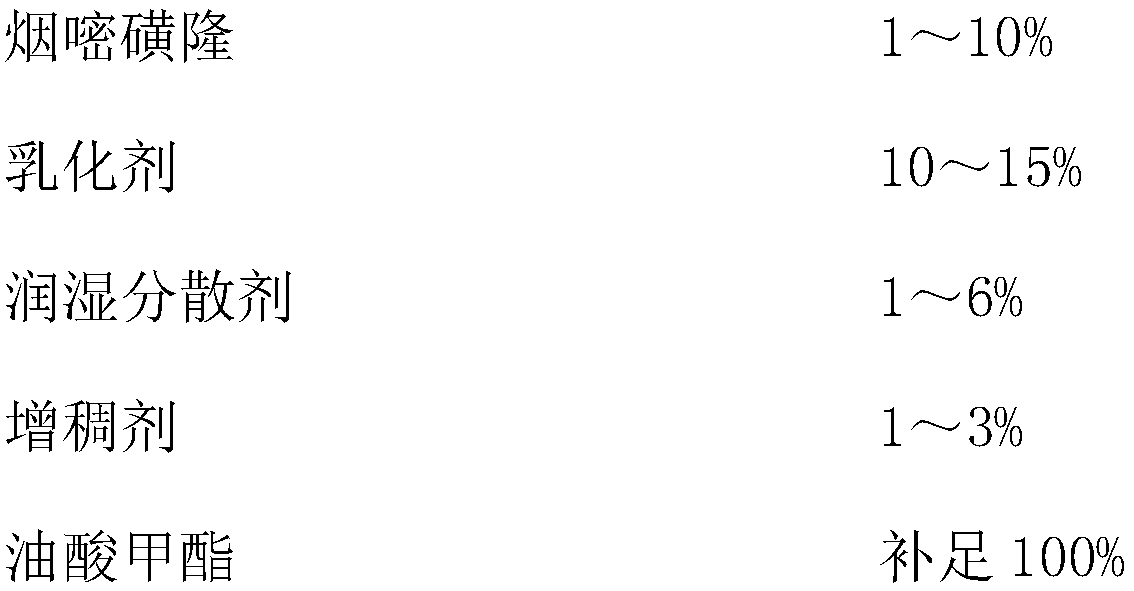

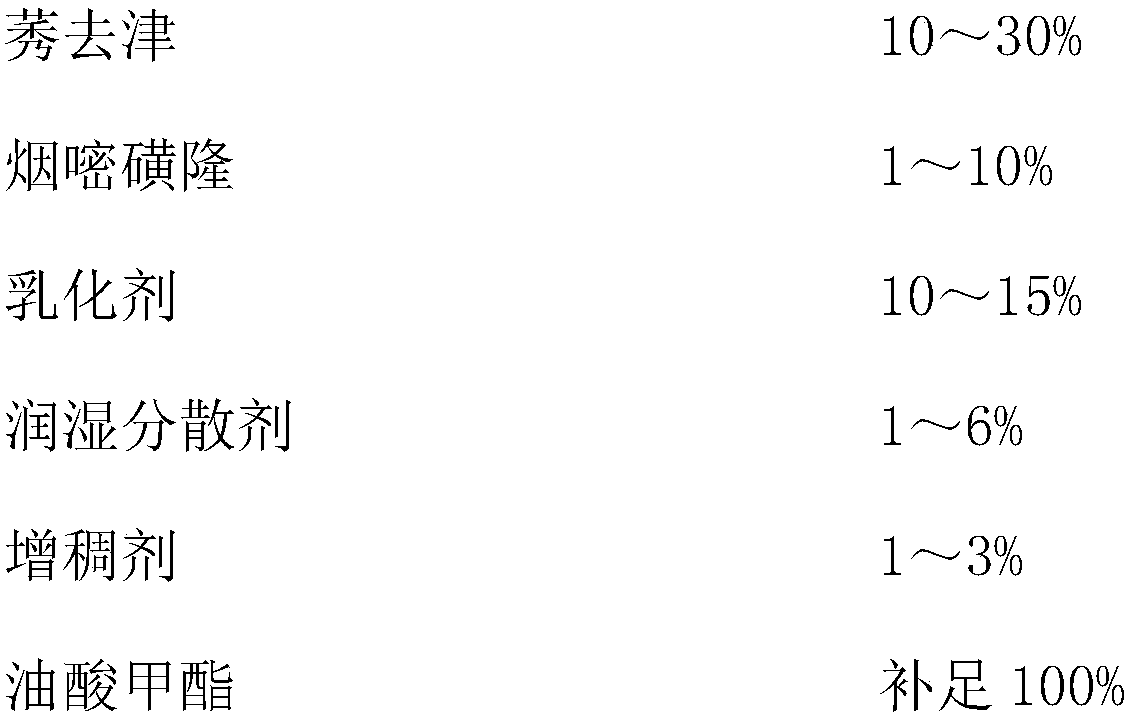

Nicosulfuron atrazine oil suspension with methyl oleate as dispersing medium and preparation method thereof

The invention discloses a nicosulfuron atrazine oil suspension with methyl oleate as a dispersing medium. The nicosulfuron atrazine oil suspension with the methyl oleate as the dispersing medium is characterized by comprising the following components in percentage by weight: 10-30% of atrazine, 1-10% of nicosulfuron, 10-15% of an emulsifying agent, 1-6% of a wetting dispersant, 1-3% of a thickening agent and 100% of methyl oleate ; the dispersant is sulfate dispersant; the emulsifying agent is one or a combination of two or more than two of NP-series phosphate polyoxyethylene nonylphenol, AEO-series fatty alcohol-polyoxyethylene ether, high-molecular EO-PO block copolymer, alkylphenol polyoxyethylene phosphate, alkylphenol polyoxyethylene, Span series, styrene phenol polyoxyethylene polyoxypropylene amine ether and pesticide emulsifier 500#. Problems of high viscosity, poor spontaneous emulsification, austenite curing and the like in the emulsifying agent processing are obviously solved; an inclusion colloidal suspension is formed so that the migration of a pesticide in soil is small, no pollution to underground water is realized, and the production and use are safe.

Owner:SHANGHAI NORMAL UNIVERSITY

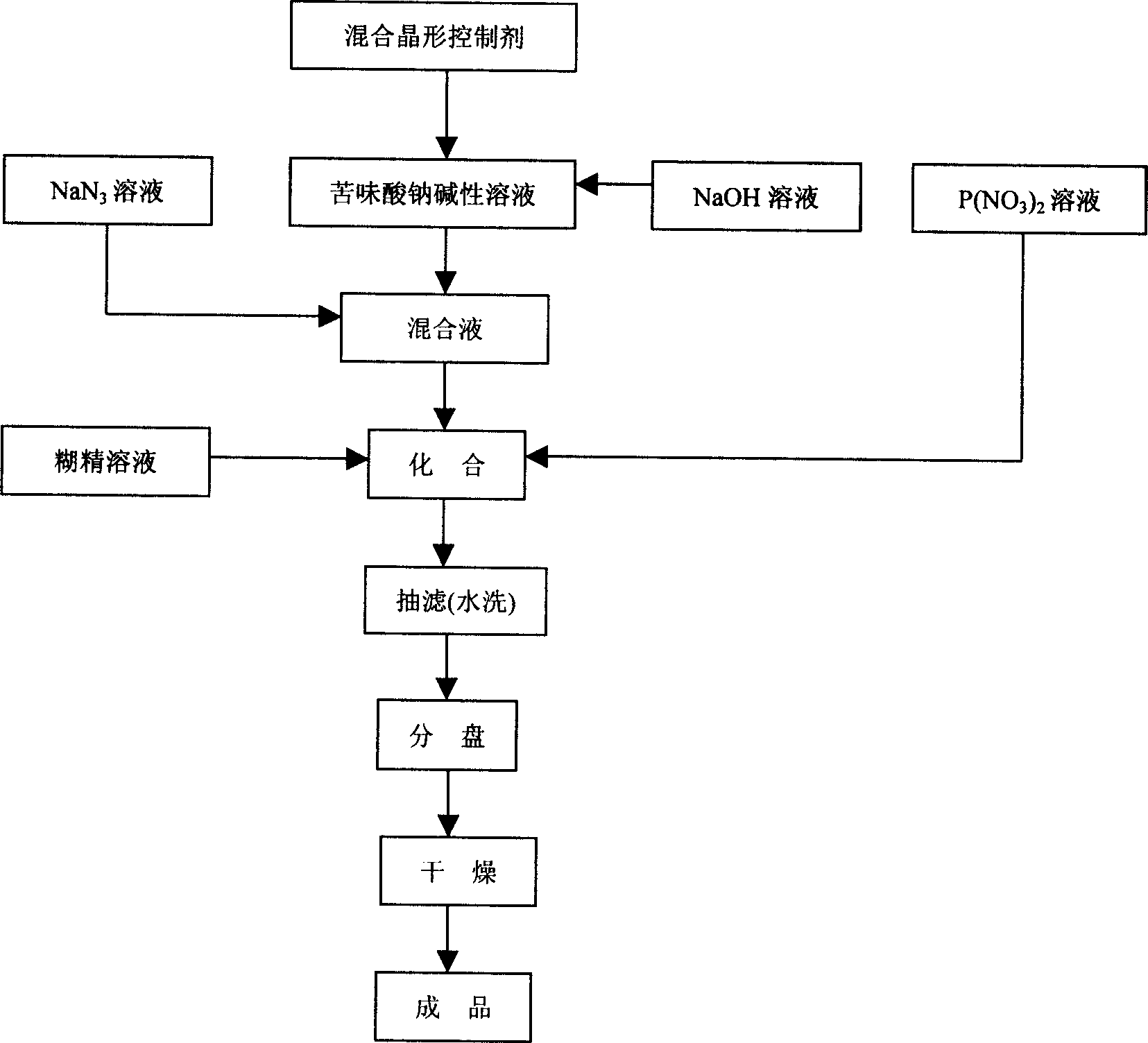

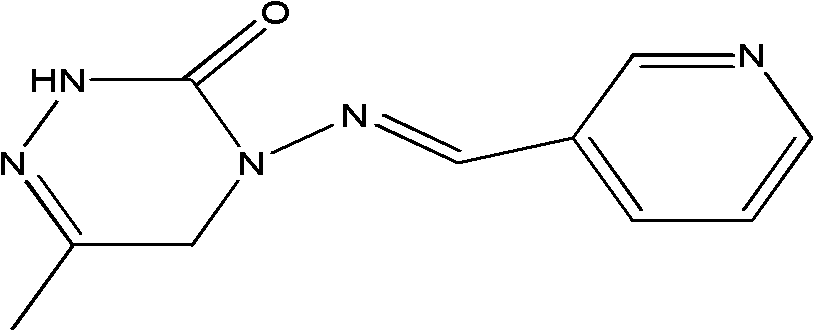

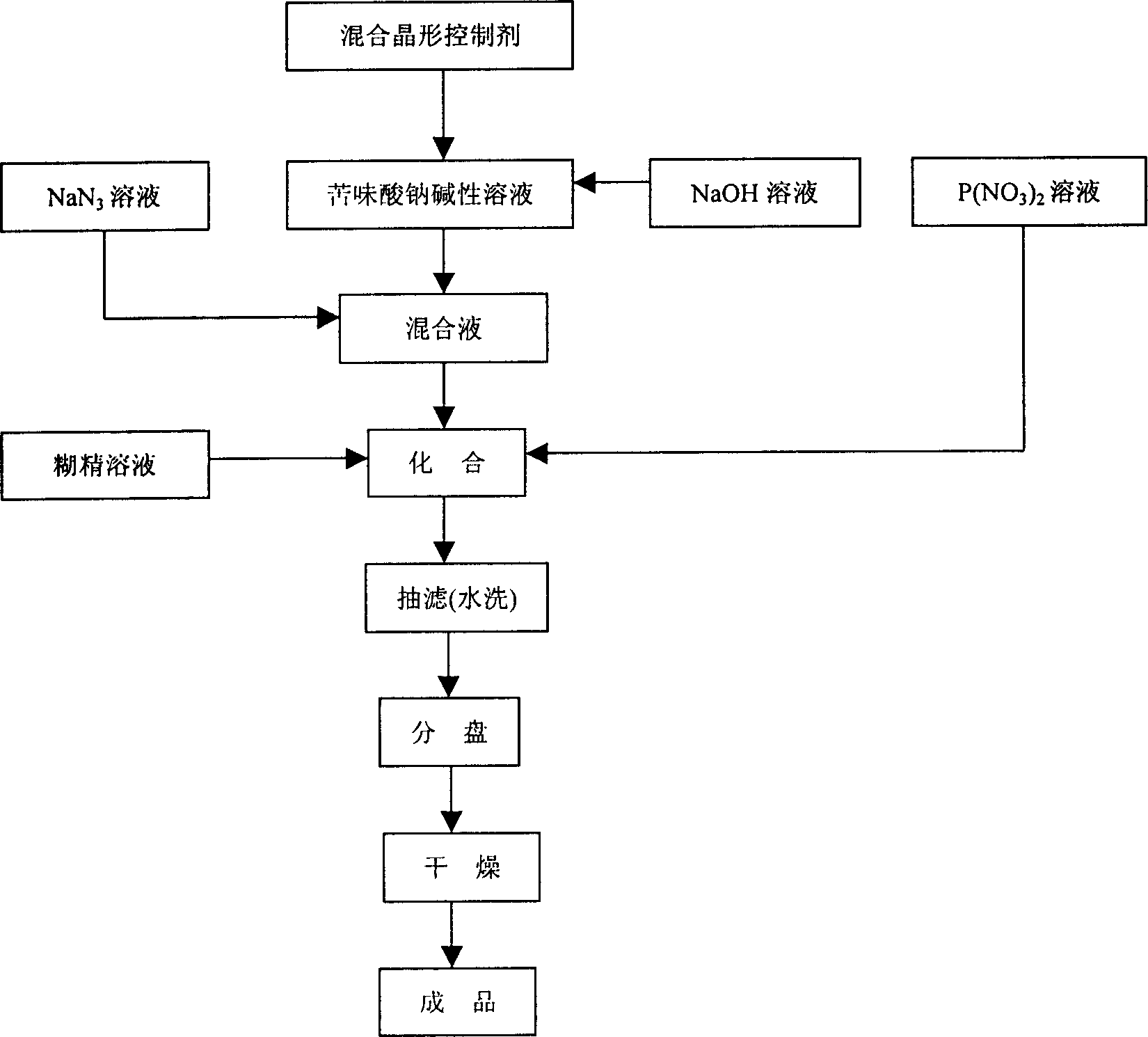

Method for preparing burster of double salt of spherical alkali type lead picrate and azide lead

InactiveCN1727315AImprove detonation abilityImprove pressure resistanceNitrated metallo-organic explosive compositionsLead nitrateDouble salt

A spherical detonating explosive is prepared through mixing the composite crystal form controlling agent, sodium azide and the alkaline solution of sodium picrate to obtain mixed solution, adding dextrin solution to the solution of lead nitrate to obtain basic solution, adding less mixed solution to the basic solution, adding rest of mixed solution to the basic solution at 65-80 deg.C within 30-60 min, regulating pH value, siphonating mother liquid, and water washing. Its advantages are high compression resistance, detonating power, flame sensitivity and thermal stability, and no environmental pollution.

Owner:NANJING UNIV OF SCI & TECH

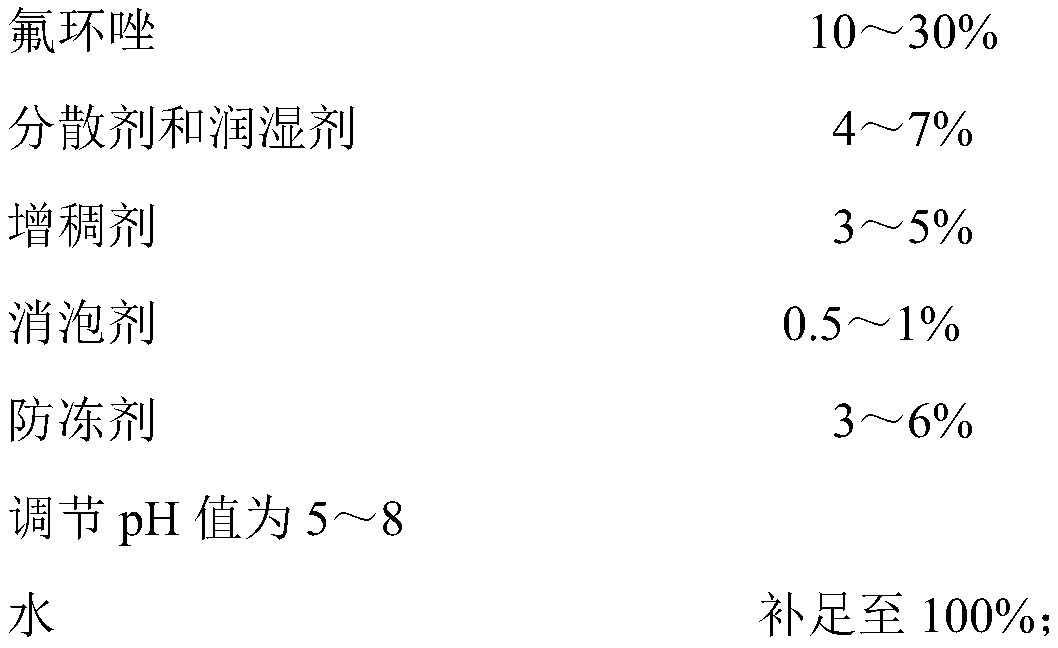

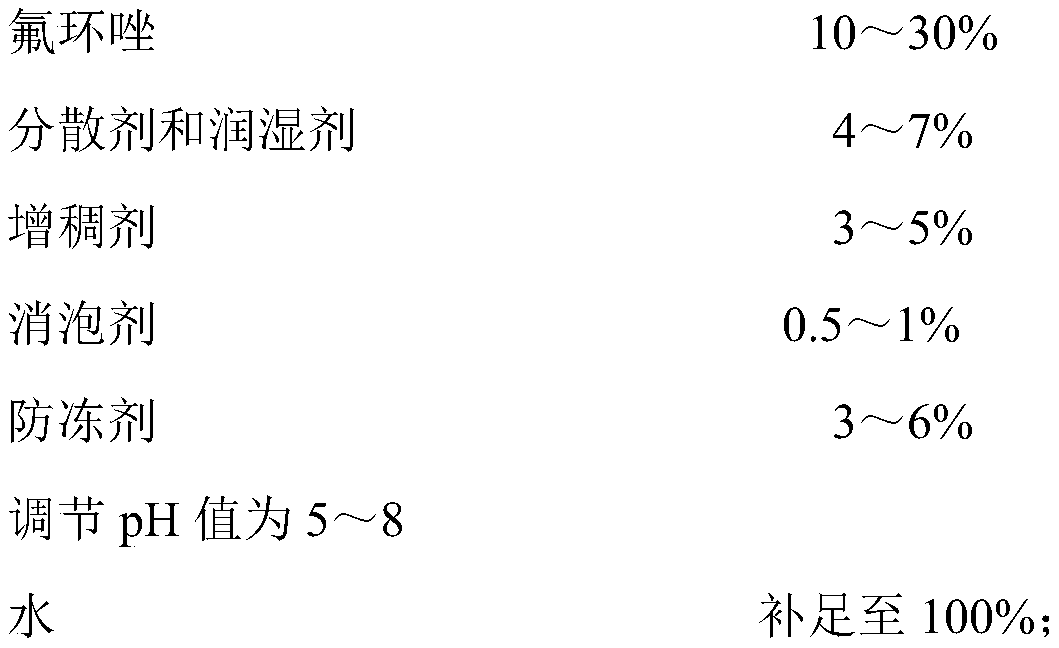

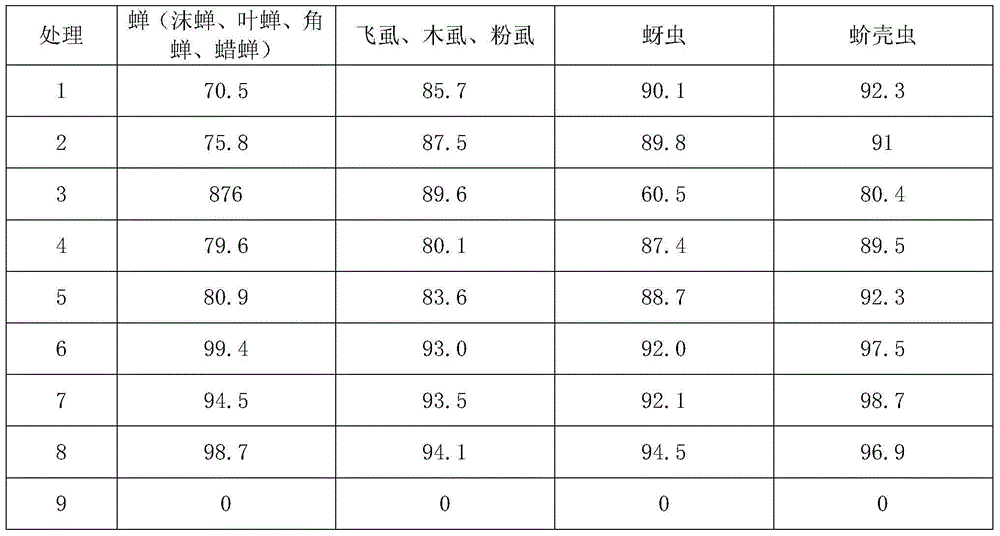

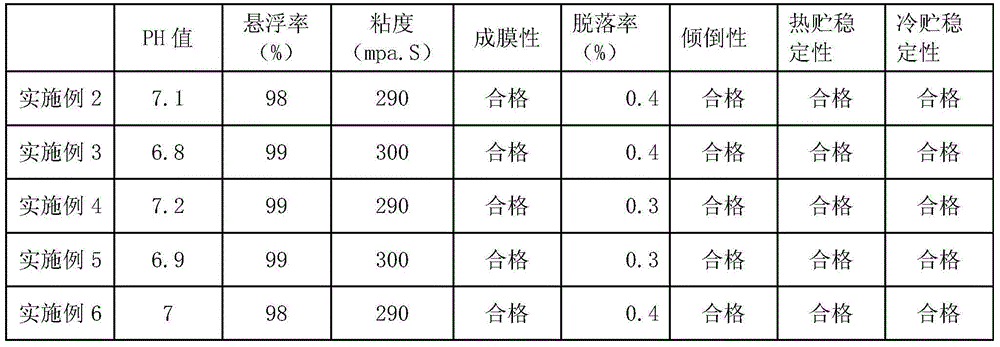

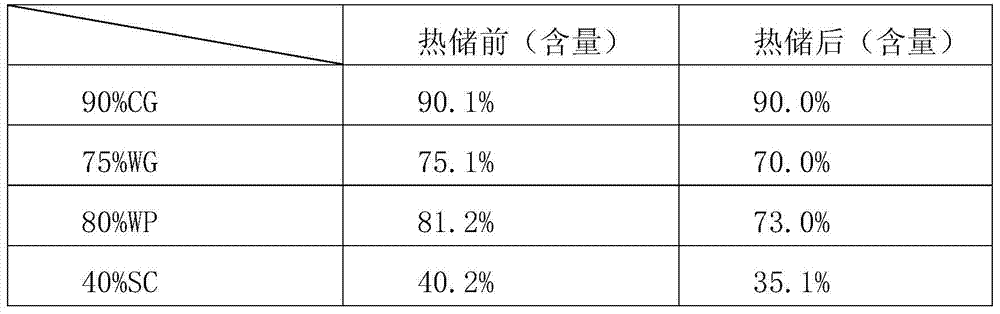

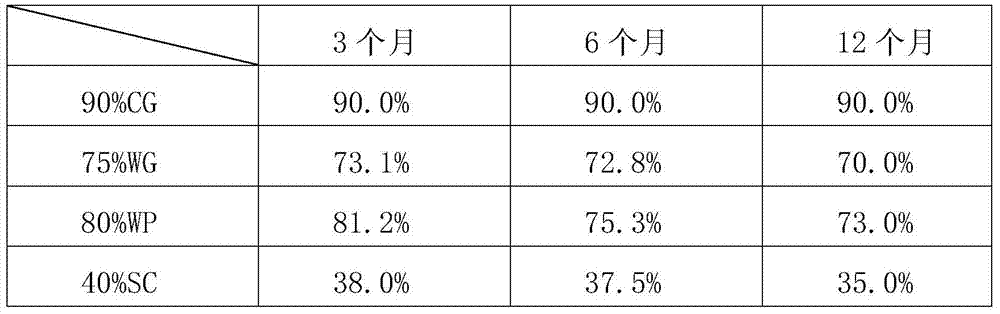

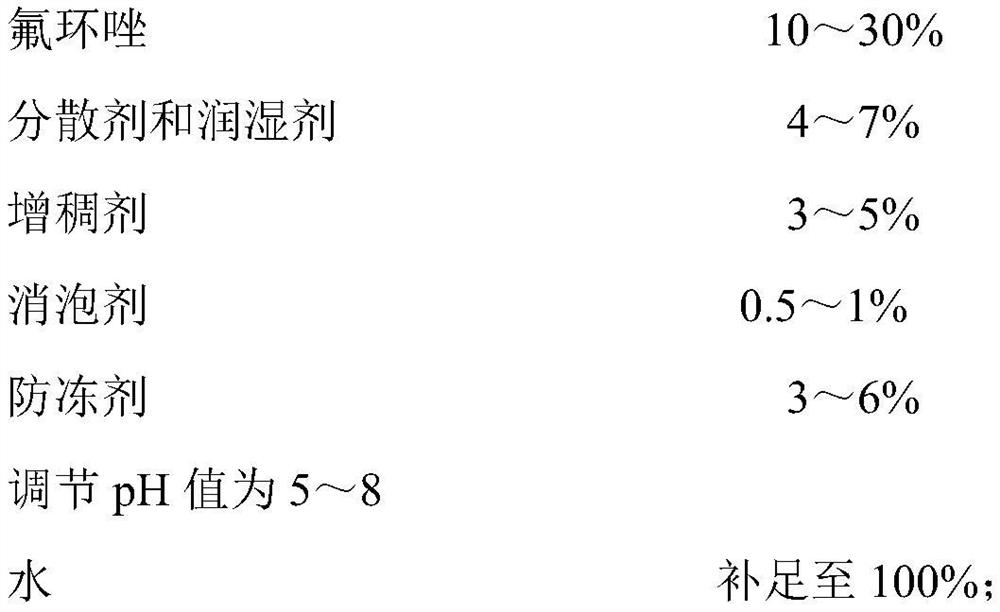

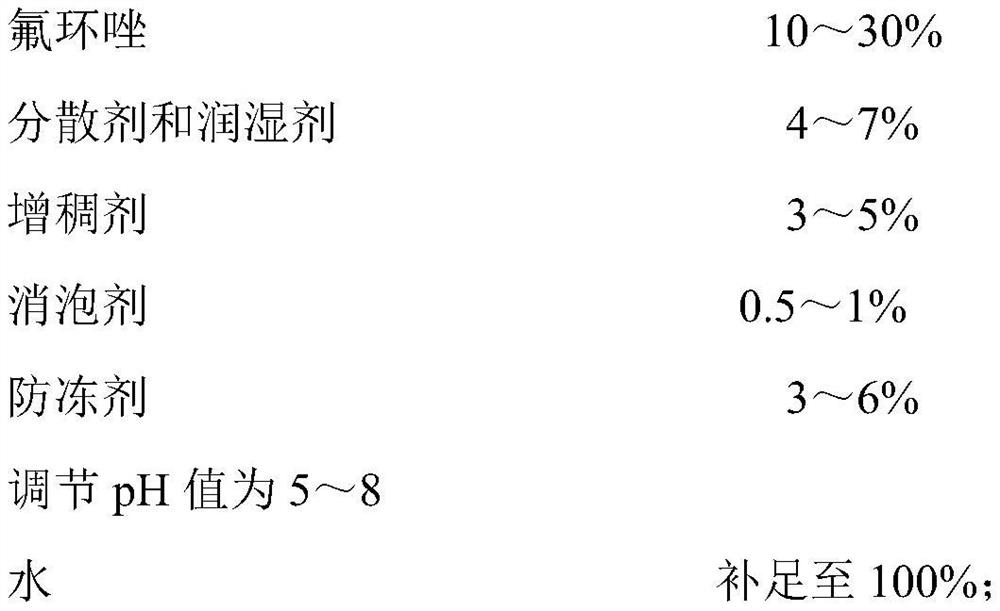

Epoxiconazole water suspension agent and preparation method thereof

ActiveCN109699653ALow viscosityHigh suspension rateBiocideFungicidesDefoaming AgentsOstwald ripening

The invention discloses an epoxiconazole water suspension agent and a preparation method thereof. The epoxiconazole water suspension agent is composed of the following components in percentage by weight: 10-30% of epoxiconazole, 4-7% of dispersant and wetting agent, 3-5% of thickening agent, 0.5-1% of defoaming agent, 3-6% of antifreezing agent and water replenished to reach 100%, wherein the pH value is regulated to 5-8; the dispersant is a tristyrylphenol polyoxyethylene ether sulfate dispersant; the wetting agent is selected from one or a combination of more than two of NP-series nonylphenol polyoxyethylene ether, AEO-series fatty alcohol polyoxyethylene ether, a polymer EO-PO block copolymer, alkylphenol polyoxyethylene and styrylphenol polyoxypropylene ether. The problems such as poorheat (cold) storage stability, more foam, poor automatic dispersibility and ostwald ripening in suspension agent processing are remarkably reduced.

Owner:SHANGHAI NORMAL UNIVERSITY

Novel suspended seed coating

InactiveCN104970036AGuaranteed germination rateGood effectPlant growth regulatorsBiocideAdjuvantFipronil

The invention discloses a novel suspended seed coating. The novel suspended seed coating comprises the following main ingredients in percentage by mass: 10-30% of imidacloprid, 10-30% of fipronil, 1-10% of pyraclostrobin, a proper amount of adjuvant and the balance of distilled water. The novel suspended seed coating disclosed by the invention is good in drug effect, long in effect duration and high in effect, is economical and safe and can be used for reducing the pollution to environment, increasing the utilization ratio of pesticides, lowering the consumption of the pesticides, thereby being worthy of widespread popularization and use.

Owner:山东罗邦生物农药有限公司

Water-based preparation containing lice mites urea and preparation method thereof

ActiveCN101647429ANarrow particle size distributionImprove stabilityBiocideAnimal repellantsWater basedUltrasound - action

The invention provides a water-based preparation containing lice mites urea and a preparation method thereof. The preparation comprises the following agricultural effective components in percentage bymass: 1-15 lice mites urea and 1-10 abamectin or emamectin benzoate as well as latent solvent, solvent and a surface active agent. in the preparation, an oil phase is added to a water phase and the oil phase and water phase are dispersed under the action of ultrasonication. Compared with other preparation formulations containing lice mites urea in the prior art, the water-based preparation has simple production equipment, short preparation time, smaller grain diameters between a traditional microemulsion and an aqueous emulsion and thermodynamic stability without an ntifreeze and a thickeningagent, reduces the use of a great amount of the organic solvent and the surface active agent and accords with the requirement for environmental protection.

Owner:SHENZHEN NOPOSION AGROCHEM

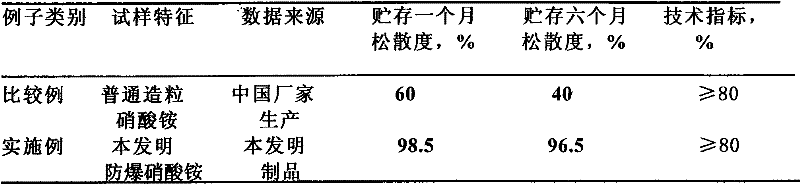

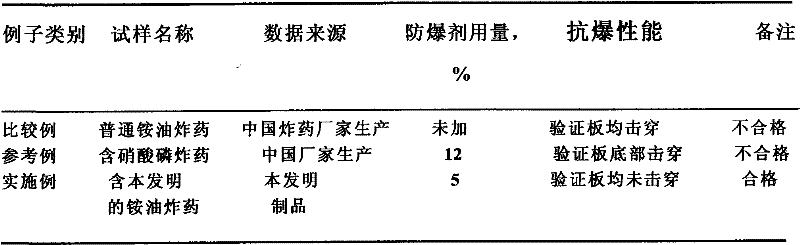

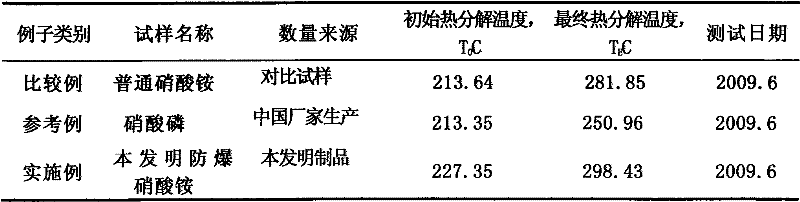

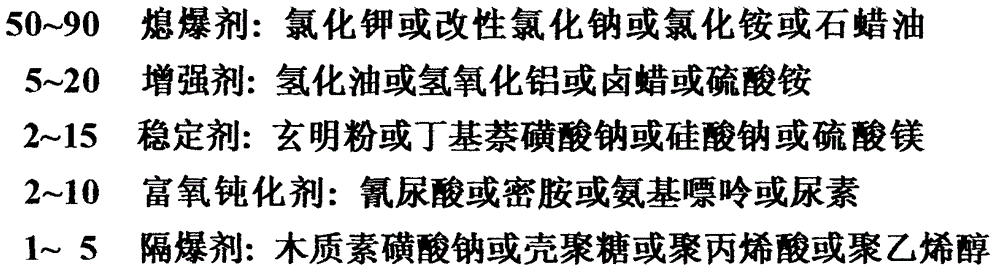

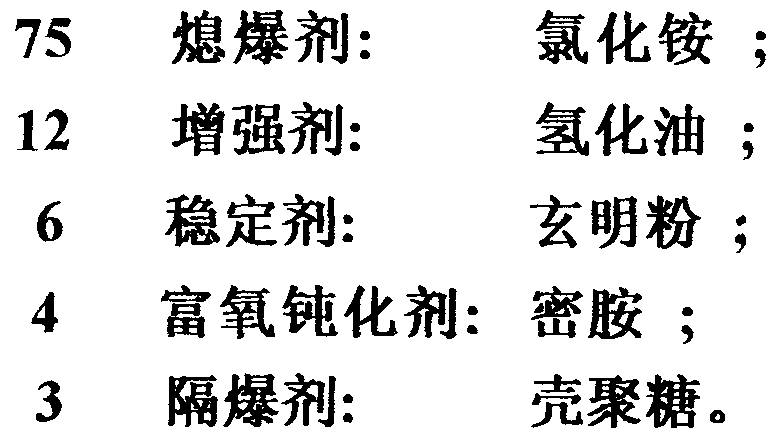

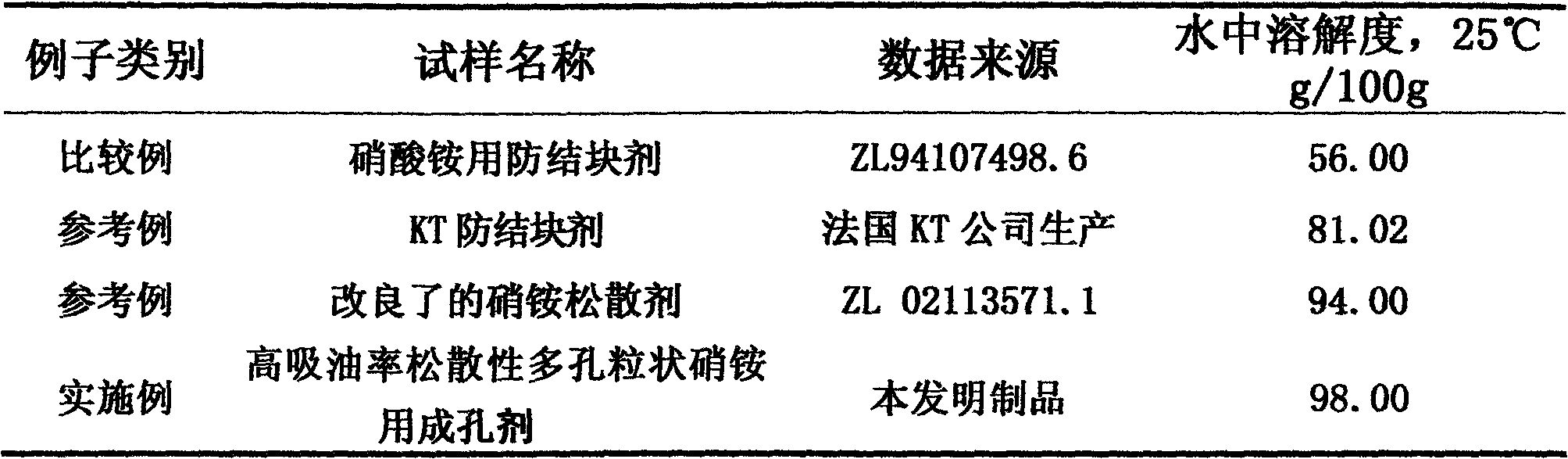

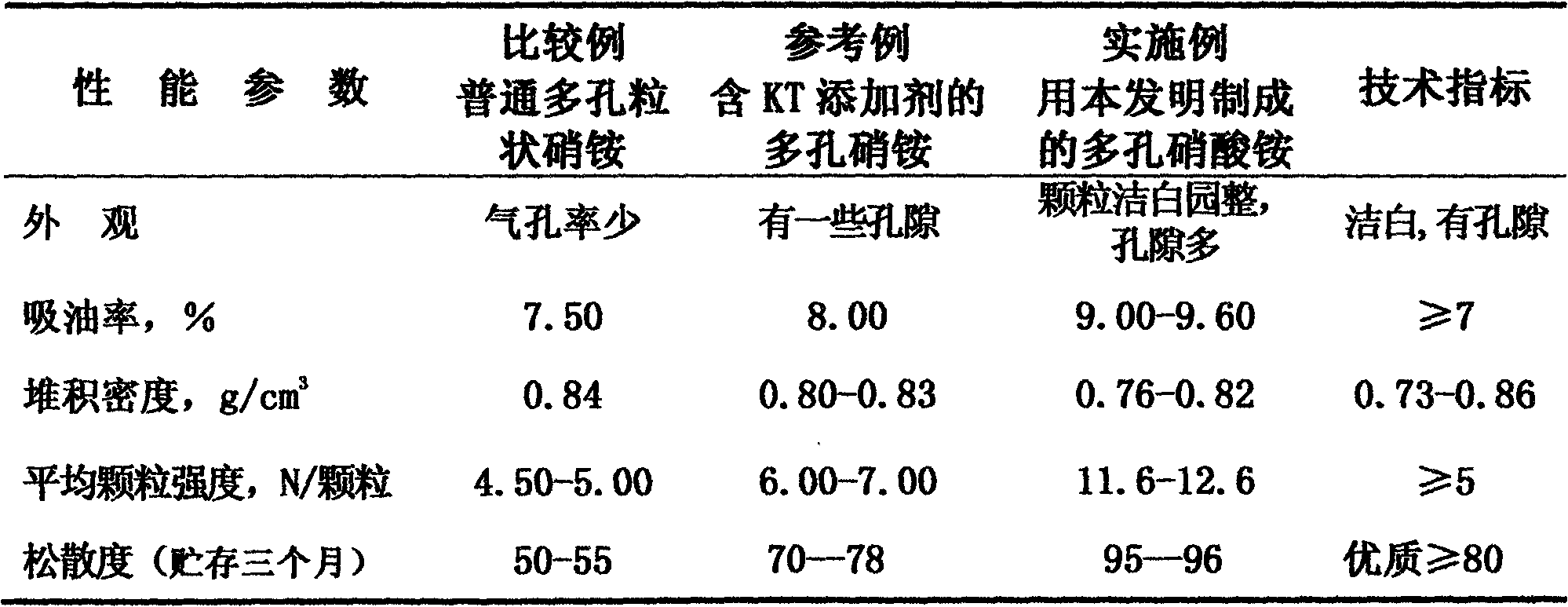

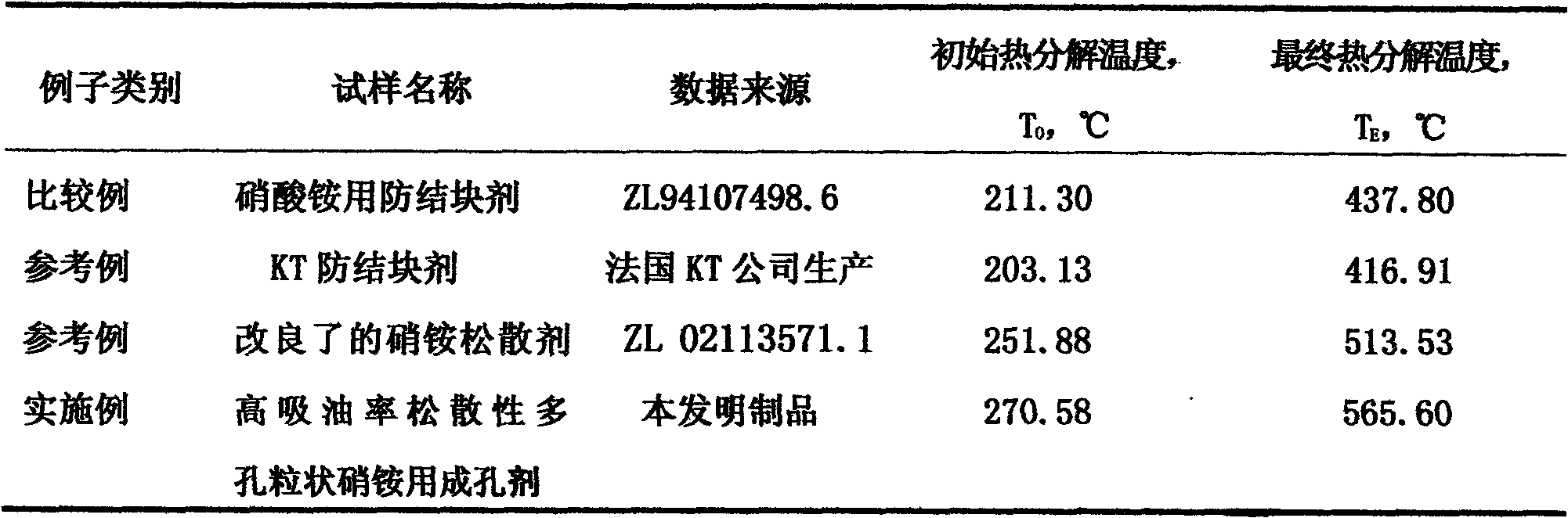

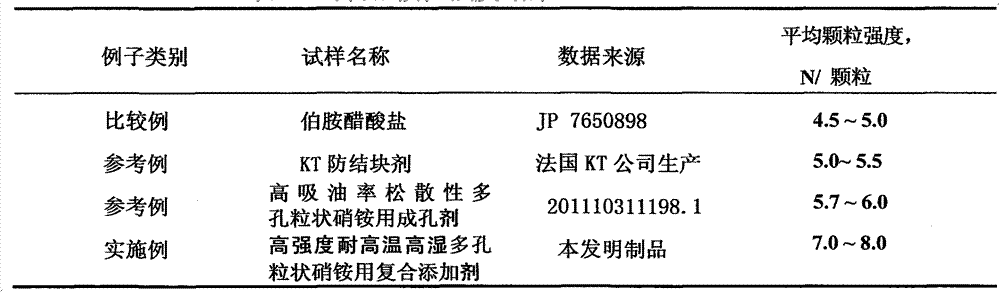

Loose explosion proof ammonium nitrate for agricultural use containing water soluble antidetonant and preparation thereof

ActiveCN101602631BLoss of explosive propertiesAvoid easy clogging of granulation nozzlesAmmonium nitrate fertilisersFertilizer mixturesSolubilityWater soluble

The invention provides a loose explosion proof ammonium nitrate for agricultural use, which is characterized by containing water soluble powdery antidetonant, and preparation thereof. The invention aims to solve the technological defects of antidetonants for ammonium nitrate modification developed in the prior art such as undesired water solubility in practical use, easy separator of ammonium nitrate from the mixture, easiness in blocking pelleting spray by the antidetonant, bad explosion prevention effect, hardening easiness during the product storage. The water soluble powdery antidetonant includes an explosion inhibitor, a flame retardant, a crystallization resistant, a heat resistant, and a penetration inhibitor. The explosion inhibitor and the ammonium nitrate liquor is added into a mixing groove in front of the pelleting spray at the same time and stirred uniformed, continuously pelleted by a rotation spray so that explosion proof granular ammonium nitrate which is loose, explosion resistant and unable to be recovered is obtained. The invention also can be used as an effective antidetonant modified from powdery crystal ammonium nitrate.

Owner:殷海权 +1

Organic selenium-enriched liquid fertilizer and preparation method thereof

ActiveCN101817710BProduction and use safetyImprove absorption efficiencyFertilizer mixturesDiseaseKeratin

The invention discloses an organic selenium-enriched liquid fertilizer and a preparation method thereof. The organic selenium-enriched liquid fertilizer comprises the following components in percentage by weight: more than or equal to 10 percent of total animal keratin hydrolyzed amino acid, 0.1 to 3 percent of organic selenium in terms of selenium, 2 to 3 percent of surfactant, more than or equal to 1.0 percent of trace element zinc required by plants, more than or equal to 1.0 percent of boron, and the balance of water. The invention also provides the preparation method of the organic selenium-enriched liquid fertilizer. The organic selenium-enriched liquid fertilizer is safe in production and application, can improve the selenium absorption efficiency of farm crops and improve disease and insect resisting, drought and flood resisting and yield increasing capacities of the farm crops, has the characteristics of supplementing the selenium, improving the fruit quality of the farm crops and reducing heavy metal toxicity, and has a storage life of 3 years without deterioration.

Owner:成都华宏生物科技有限公司

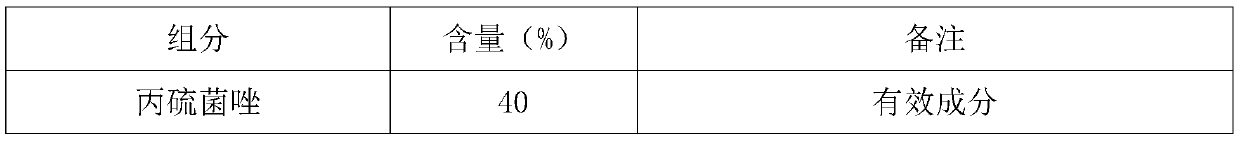

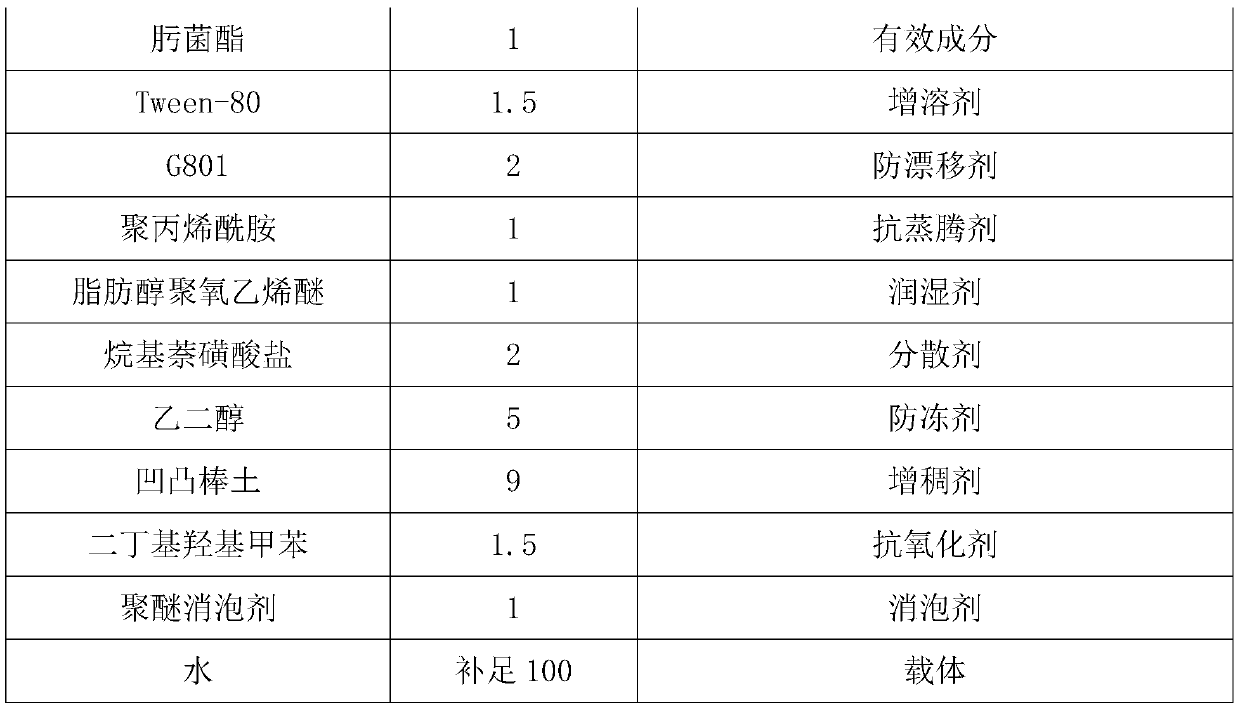

Prothioconazole intelligent microcapsule suspending agent and preparation method thereof

The invention belongs to the technical field of bactericides. The invention relates to a prothioconazole intelligent microcapsule suspending agent and a preparation method thereof. The suspending agent comprises the following components in percentage by weight: 1-5% of polypropylene oxide, 1-3% of an emulsifier, 2-40% of prothioconazole, 2-8% of caprylic / capric triglyceride, 2-8% of isopropyl myristate, 1-5% of polyacrylic acid, 1-3% of a surfactant, 0.1-0.3% of xanthan gum, 3-5% of glycerin, 0.1-0.3% of Kathon, 0.5-2% of magnesium aluminum silicate, 1-2% of hydrochloric acid and the balance of water. The preparation method comprises the following steps: preparing an oil phase, preparing a water phase, emulsifying, adjusting a pH value, microencapsulating and preparing the suspending agent. The microcapsule suspending agent disclosed by the invention has self-assembly, self-repair and high pH sensitivity, and meanwhile, the lasting period can be prolonged by slow release, and the use frequency is reduced, so that the use amount of pesticides is reduced. The method is simple in process and capable of effectively achieving mass production, and therefore the method has a high application value.

Owner:利民化学有限责任公司

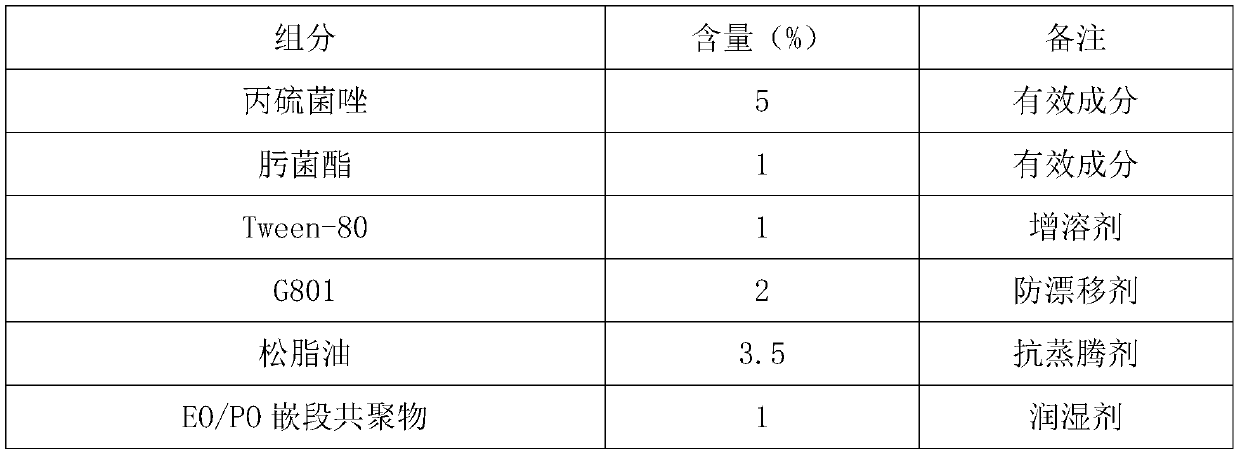

Suspending agent for flight control and preparation method of suspending agent

The invention relates to a suspending agent for flight control and a preparation method of the suspending agent. The suspending agent contains prothioconazole, trifloxystrobin, a solubilizer, an anti-drifting agent, an anti-transpiration agent and other components according to a specific ratio, has the characteristics of high flash point, fine particle size and normal particle size distribution; and the suspending agent has the characteristics of good stability at high concentration, evaporation resistance, drifting resistance and good wetting spreadability. With the suspending agent adopted,the problems of drifting, demulsification, flocculation, environmental safety and the like in flight control operation can be effectively solved.

Owner:HENAN DECI YANGNONG BIOTECH CO LTD

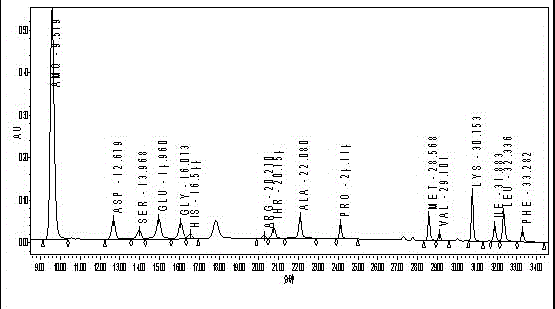

Natural composite amino acid raw material preparation method and natural composite amino acid raw material

InactiveCN104127439AProduction and use safetyEasy to useMetabolism disorderUnknown materialsHydrolysateUltrafiltration

The invention discloses a natural composite amino acid raw material preparation method. The method comprises the following steps: 1, taking cryopreserved fresh pig brain, unfreezing, cleaning, homogenating, adding the above obtained slurry to concentrated hydrochloric acid, uniformly stirring, and centrifuging to obtain precipitated brain proteins; 2, adding the precipitated proteins to sulfuric acid, hydrolyzing, adjusting the pH value to 7.5-8.5, and filtering to obtain an acid hydrolysate; 3, heating the acid hydrolysate, adding active carbon, separating, collecting the above obtained supernatant, and adjusting the pH value to 2.5-4.5 to obtain a crude extract liquid; 4, adding the crude extract liquid to a cation exchange column, adjusting the pH value to 6.5-7.5, eluting with ammonia water, collecting the obtained eluate, concentrating to remove ammonia water, adjusting the pH value to 6.5-7.5, and preserving at -20DEG C to obtain a frozen liquid; and 5, naturally unfreezing the frozen liquid, centrifuging, removing tyrosine and related impurities, collecting the newly obtained supernatant, carrying out ultrafiltration on the supernatant, collecting the obtained filtrate, and drying to obtain the desired natural composite amino acid raw material.

Owner:HUNAN LINUO BIOLOGICAL PHARMA

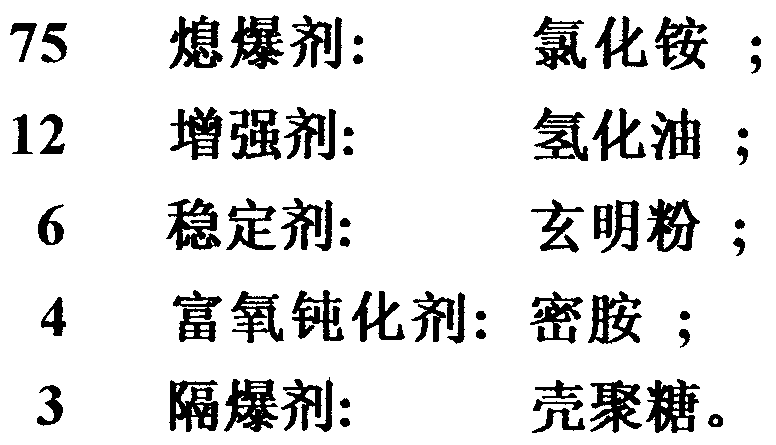

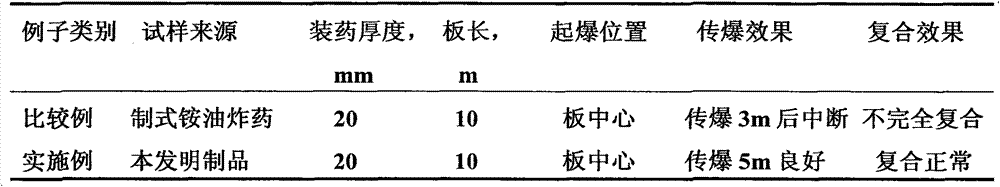

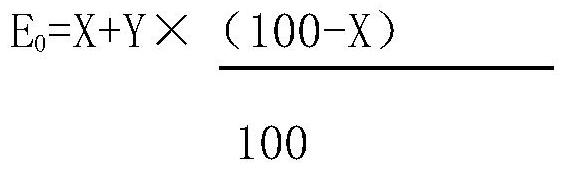

High-strength and high-stability agricultural anti-explosive ammonium nitrate and preparation method thereof

The invention provides high-strength and high-stability agricultural anti-explosive ammonium nitrate and a preparation method thereof. The high-strength and high-stability agricultural anti-explosive ammonium nitrate is characterized by comprising a compound antidetonant. The high-strength and high-stability agricultural anti-explosive ammonium nitrate aims to solve the unsolved technical defects that the antidetonant for modifying ammonium nitrate researched by predecessors in actual use is great in antidetonant adding concentration, low in particle strength of product and poor in anti-explosive effect and the product is high in probability of hardening in the storage period, unstable and non-persistent in anti-explosive performance and the like. The compound antidetonant added consists of a detonant quenching agent, an enhancer, a stabilizer, a nitrogen-enriched passivator, an explosive-proof agent and the like. According to spray granulation continuous production of a high tower and the eutectic passivation principle of the antidetonant, the antidetonant is continuously added into a molten ammonium nitrate mother liquor mixing tank in front of a granulation nozzle to be uniformly mixed and is then continuously granulated by using a rotary nozzle to prepare the agricultural anti-explosive ammonium nitrate, wherein the particle strength is greater than 30N / particle and the looseness and the anti-detonating property are stable and persistent. The adding concentration of the high-strength and high-stability agricultural anti-explosive ammonium nitrate provided by the invention is 0.5-1.0%.

Owner:殷海权

A kind of mancozeb microcapsules and preparation method thereof

Owner:利民化学有限责任公司

Flueconazole aqueous suspension and preparation method thereof

ActiveCN109699653BHigh suspension rateImprove heat storage stabilityBiocideFungicidesAlkylphenolSuspending Agents

The invention discloses an epoxiconazole aqueous suspension and a preparation method thereof, which is composed of the following components in weight percent: 10-30 percent of epoxiconazole, 4-7 percent of a dispersant and a wetting agent, and 3-5 percent of a thickener %, 0.5-1% defoamer, 3-6% antifreeze, adjust the pH value to 5-8, and make up to 100% with water; wherein the dispersant is tristyrylphenol polyoxyethylene ether sulfate dispersant; The wetting agent is selected from NP series nonylphenol polyoxyethylene ethers, AEO series fatty alcohol polyoxyethylene ethers, polymer EO-PO block copolymers, alkylphenol polyoxyethylene ethers, styrylphenol polyoxyethylene ethers, and styrene-based phenol polyoxyethylene ethers. One or a combination of two or more of propylene ethers. Significantly reduce the problems of poor heat (cold) storage stability, high foam, poor automatic dispersibility and Austenitic ripening in the processing of suspension concentrates.

Owner:SHANGHAI NORMAL UNIVERSITY

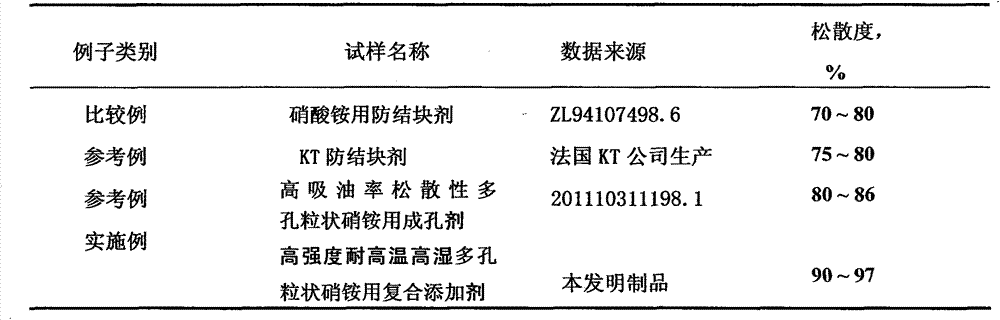

Water-soluble pore-forming agent used for bulky porous granular ammonium nitrate with high oil absorptivity

InactiveCN102503741BImprove loosenessHigh oil absorptionNon-explosive/non-thermic compositionsSpontaneous combustionNitrate

The invention relates to a water-soluble pore-forming agent for improving performances of porous granular ammonium nitrate and is characterized in that the pore-forming agent is composed of foaming agents, penetrating agents, reinforcing agents, dispersing agents, heat resistance agents and solubilizing agents. The invention aims to solve the problems in the prior art that the porous granular ammonium nitrate additive has poor oil absorptivity during practical use, the granulation sprayer is liable to be blocked during production process, the additive deposits on the filter screen are carbonized to cause spontaneous combustion, the imported raw materials have high cost, and the wrapping agent is inconvenient to use. The invention has the following characteristics: all the components of the pore-forming agent dissolve completely in water, which prevents the sprayer from being blocked during granulation process after the pore-forming agent is mixed with molten ammonium nitrate and ensures safety in ammonium nitrate mother liquid large-loop operation. The pore-forming agent is used as an effective additive for preparation of bulky porous granular ammonium nitrate with high oil absorptivity, and is also used as a moisture-proofing and anti-caking additive for preparation of bulky granular ammonium nitrate, bulky crystal ammonium nitrate and bulky nitrates. The amount of addition of the pore-forming agent is 0.08% to 0.12%.

Owner:殷海权

A kind of antifreeze production increasing composition that can be used for aerial protection

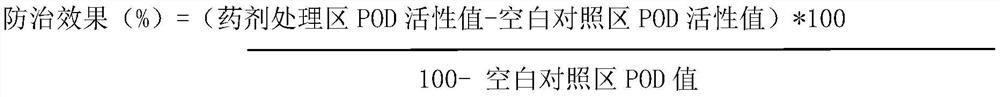

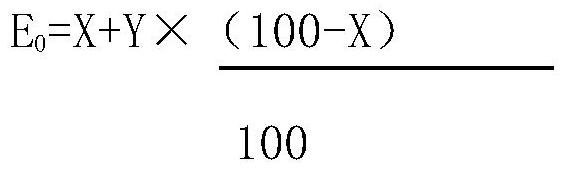

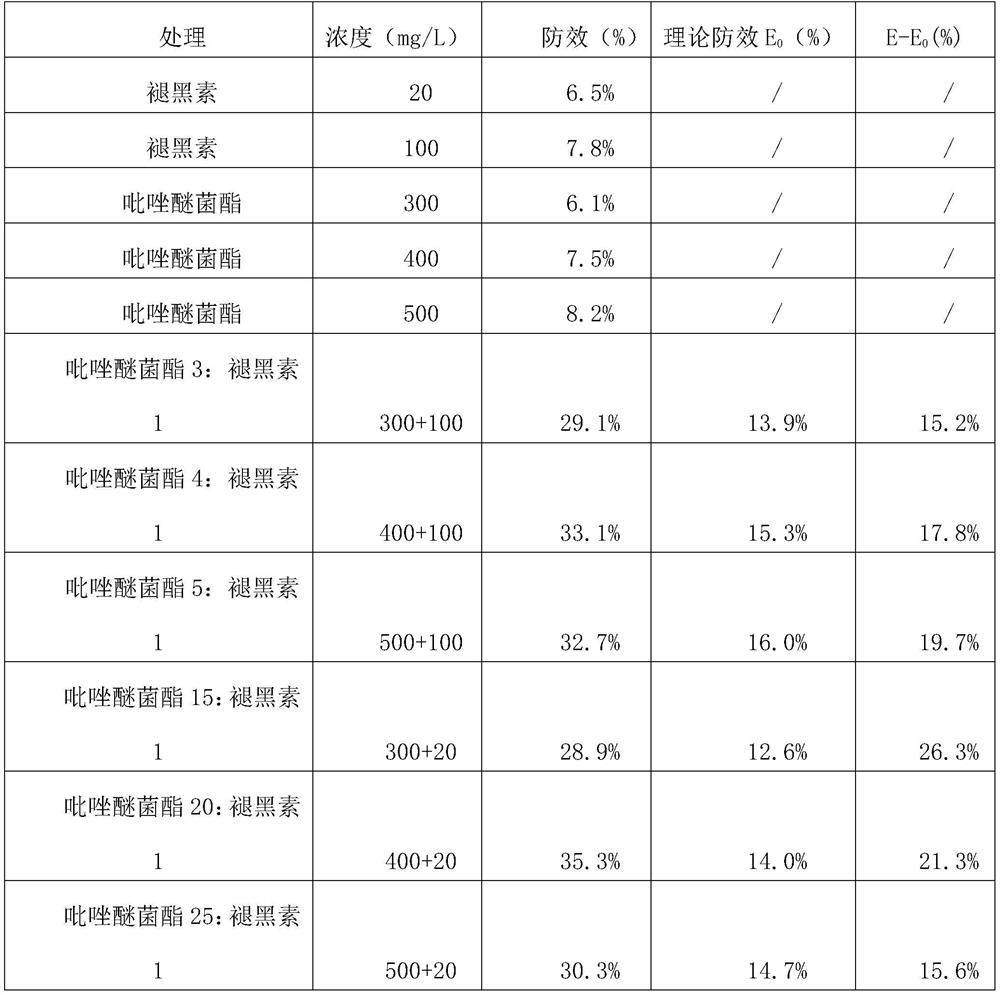

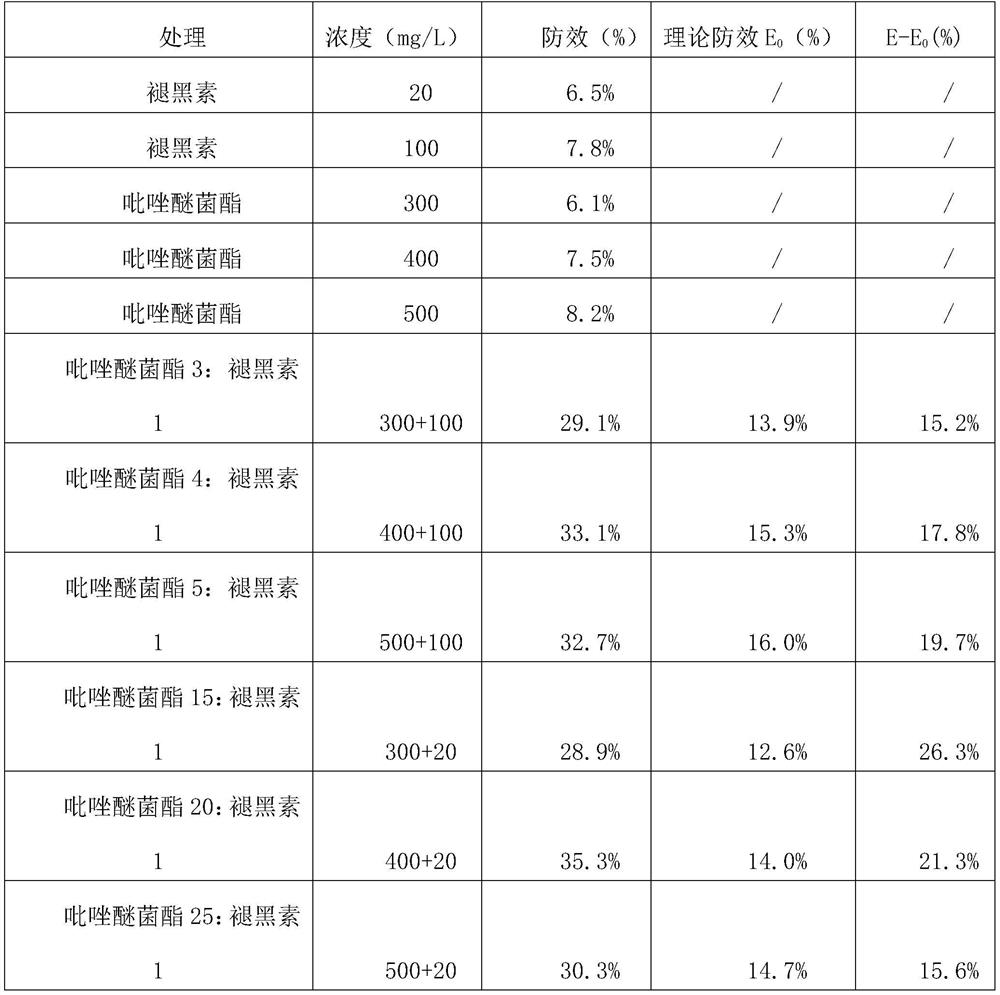

ActiveCN112167258BImprove frost resistanceIncrease final yieldBiocidePlant growth regulatorsThiamethoxamOrganosolv

The invention discloses an antifreeze yield increasing composition which can be used for aerial defense and a preparation method thereof. The composition contains melatonin, pyraclostrobin and thiamethoxam in specific proportions. The composition of the invention can effectively solve the problems of airtightness, demulsification, flocculation, etc. in aerial defense operations, does not contain organic solvents, is safe in production and use, and is environmentally friendly; it can significantly improve the frost resistance of crops, and delay the adverse effects of freezing damage on crops ; It can also increase the thousand-grain weight and improve the final yield of crops.

Owner:HENAN DECI YANGNONG BIOTECH CO LTD

Water-based preparation containing lice mites urea and preparation method thereof

ActiveCN101647429BProduction and use safetyReduce dosageBiocideAnimal repellantsUltrasound - actionActive agent

The invention provides a water-based preparation containing lice mites urea and a preparation method thereof. The preparation comprises the following agricultural effective components in percentage by mass: 1-15 lice mites urea and 1-10 abamectin or emamectin benzoate as well as latent solvent, solvent and a surface active agent. in the preparation, an oil phase is added to a water phase and the oil phase and water phase are dispersed under the action of ultrasonication. Compared with other preparation formulations containing lice mites urea in the prior art, the water-based preparation has simple production equipment, short preparation time, smaller grain diameters between a traditional microemulsion and an aqueous emulsion and thermodynamic stability without an ntifreeze and a thickening agent, reduces the use of a great amount of the organic solvent and the surface active agent and accords with the requirement for environmental protection.

Owner:SHENZHEN NOPOSION AGROCHEM

Composite additive for high-strength high temperature and high moisture resisting porous granular nitramine

InactiveCN103113173BHigh particle strengthImprove moisture and moisture resistance physical propertiesNon-explosive/non-thermic compositionsPrillAnticaking agent

The invention relates to a waterborne composite additive which can improve the physical properties of porous granular nitramine. The composite additive is characterized by consisting of internally added full water soluble powder and an ointment-shaped outer wrapping agent. The internally added full water soluble powder consists of an enhancer, an anti-crystal change agent, a diffusant and the like. The ointment-shaped outer wrapping agent consists of a water repellent, an anti-crystal change agent, an enhancer and the like. The composition additive is provided by the invention to overcome the deficiencies of additive for porous granular nitramine researched by predecessors that the porous granular nitramine product is low in strength, easy to block in high temperature and moist environments, more foam in production process of powder aqueous liquor, high cost due to imported raw materials and the like in actual use. The composite additive has the characteristics that not only is high-strength porous granular nitramine prepared, but also the product can be stored for three months in high temperature and moist environments, and the shatter value is maintained at 90%. The composite additive provided by the invention can be further used as an effective anti-blocking agent for preparing a high nitrogen nitryl compound fertilizer. The fortified concentration of the composite additive provided by the invention is 0.10-0.12%.

Owner:太原海力丰科技发展有限公司

Polyoxin soluble gel and preparation method thereof

PendingCN114190396ADosage stableEasy to operateBiocideFungicidesOrganic chemistryBiomedical engineering

The invention relates to a polyoxin soluble gel agent and a preparation method thereof, the polyoxin soluble gel agent is obtained by fully utilizing a precipitate obtained after a polyoxin mother liquor is stored for a long time and adding a wetting dispersant, a defoaming agent, a solubilizer and a pH regulator, and the product is stable in dosage form, simple to operate, low in production cost and easy to popularize and use.

Owner:陕西麦可罗生物科技有限公司

Anti-freezing yield-increasing composition for flight control

ActiveCN112167258AImprove frost resistanceIncrease final yieldBiocidePlant growth regulatorsFlocculationOrganic solvent

The invention discloses an anti-freezing yield-increasing composition for flight control and a preparation method thereof. The composition comprises melatonin, pyraclostrobin and thiamethoxam in a specific proportion. The composition disclosed by the invention can effectively solve the problems of drifting, demulsification, flocculation and the like in flight control operation, does not contain organic solvents, is safe to produce and use, and is environment-friendly; the anti-freezing property of crops can be remarkably improved, and the adverse effect of freezing injury on the crops is delayed; besides, the thousand-seed-weight can be increased, and the final yield of crops is increased.

Owner:HENAN DECI YANGNONG BIOTECH CO LTD

Reinforced polyethylene pipe with super high molecular weight, manufacturing method and apparatus thereof

InactiveCN1284944CReduce manufacturing costLow fatigue resistanceRigid pipesTubular articlesPlastic pipeworkEngineering plastic

The invention provides a reinforced ultra-high molecular weight polyethylene pipe and its manufacturing method and equipment. Its tensile strength is about 50Mpa, and the pipe wall thickness is 60-60% of the PE100 pipe wall thickness under the same pipe diameter and the same working pressure. 75%, which is 70-85% of the wall thickness of UHMWPE pipes. Provide a product with light weight, high strength, high wear resistance and high fatigue resistance for engineering plastic pipes under the premise of thin pipe wall and low manufacturing cost. The detection of the present invention proves: the tensile strength is about 50Mpa, and the impact strength is 130KJ / M 2 The wear resistance is about 4-7 times that of steel, 4 times that of nylon, and 3 times that of PE100. The resistance to environmental stress cracking is more than 4,000 hours, the fatigue resistance is about 800,000 times, and the low temperature resistance is at -40°C. The lower impact strength does not drop but reaches the highest value. The product cost of the invention is about 35% lower than that of PE100 pipes and ultra-high molecular weight polyethylene pipes, and the invention also has the advantages of safe and reliable production and use, and low engineering cost.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

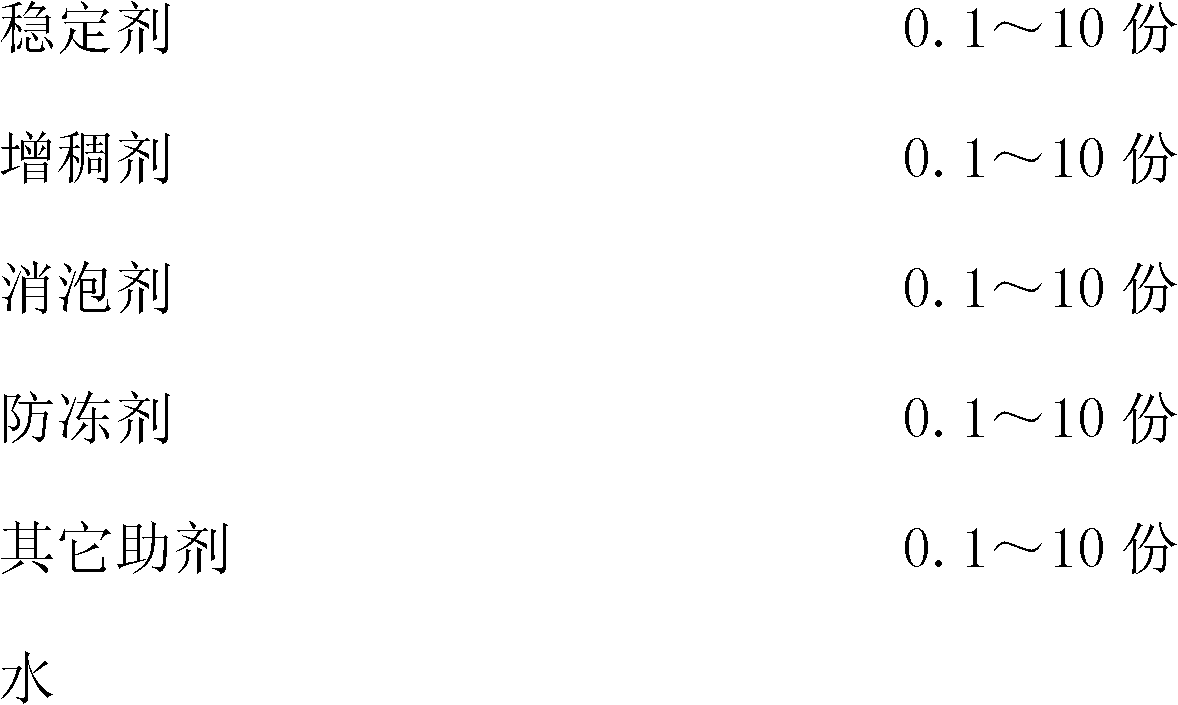

Pymetrozine suspension and preparation method thereof

ActiveCN102283193BUniform particle size distributionImprove stabilityBiocideArthropodicidesAnti freezingBall mill

The invention belongs to the technical field of pesticide application, and discloses pymetrozine suspension and a preparation method thereof. The preparation method comprises the following steps of: adding water into 10 to 60 parts of pymetrozine, 1 to 30 parts of dispersant, 0.1 to 10 parts of stabilizer, 0.1 to 10 parts of thickener, 0.1 to 10 parts of defoaming agent, 0.1 to 10 parts of anti-freezing agent and 0.1 to 10 parts of other auxiliary agents till complementing to 100 weight parts, performing ball milling for 2 to 3 hours in a ball mill till the suspension particle diameter of the materials is 1 to 3 microns, filtering, and thus obtaining the pymetrozine suspension. The particle diameter distribution of the pymetrozine water suspension is uniform, and 95 percent of average particle diameter is between 2 and 3 microns; and the suspension has good stability and good thermal storage stability, and the normal-temperature suspension rate reaches over 96 percent.

Owner:SHANGHAI NORMAL UNIVERSITY

Manufacturing method of long-acting insecticidal fountain pen

InactiveCN111374146AEasy to prepareQuick killBiocideAnimal repellantsOrganosolvEnvironmental geology

The invention discloses a manufacturing method of a long-acting insecticidal fountain pen. An insecticide is stored in the insecticidal fountain pen; the insecticide comprises the following componentsin parts by weight: 1-2 parts of a high-efficiency and low-toxicity pyrethroid insecticide, 1-3 parts of a nano resin material, 0.5-1 part of a stabilizer, 50-80 parts of an organic solvent, 0.1-2 parts of a preservative, 10-30 parts of deionized water and 0.1-1 part of an antioxidant. The preparation method is simple, and the traditional methods such as cockroach killing chalks, insect killing spray liquid, cockroach killing poison baits, cockroach killing stickers, cockroach sticking plates, cockroach killing powder, spraying and pesticide coating are replaced, so that the environment is polluted, the pest killing effect is poor, and the long-acting effect cannot be achieved. The high-efficiency and low-toxicity pyrethroid insecticide is compounded with other protective auxiliaries to obtain a long-acting pest killing fountain pen, a nano pest killing film is formed, cockroaches, ants and other pests can be safely and rapidly killed, the pests can be rapidly killed within three weeks, the long-acting effect is achieved, and the effective rate is 99.2%. Production and use are safe and convenient.

Owner:江苏建儒有害生物防制管理咨询有限公司

Method for preparing burster of double salt of spherical alkali type lead picrate and azide lead

InactiveCN1300070CImprove detonation abilityImprove pressure resistanceNitrated metallo-organic explosive compositionsLead nitrateSodium azide

A spherical detonating explosive is prepared through mixing the composite crystal form controlling agent, sodium azide and the alkaline solution of sodium picrate to obtain mixed solution, adding dextrin solution to the solution of lead nitrate to obtain basic solution, adding less mixed solution to the basic solution, adding rest of mixed solution to the basic solution at 65-80 deg.C within 30-60 min, regulating pH value, siphonating mother liquid, and water washing. Its advantages are high compression resistance, detonating power, flame sensitivity and thermal stability, and no environmental pollution.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com