Preparation method of polysilicate ferric chloride flocculant

A technology of polysilicate ferric chloride and polyferric chloride, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as adverse environmental impact, complicated process, and environmental pollution, and achieve safe production and use and simple production process , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, preparation polysilicate ferric chloride flocculant:

[0021] 1) Preparation of polyferric chloride: Weigh 5g of hematite powder (150 mesh), add 34.3ml of industrial hydrochloric acid with a concentration of 6mol / L, react in a water bath heater, control the temperature at 75°C, and stir After reacting for 2 hours, filter, adjust the pH value of the solution with sodium hydroxide in a water bath at 38°C, and control the pH value of the solution to 1.4, react for 28 minutes, and then mature for 24 hours to obtain a polyferric chloride solution with a certain degree of polymerization.

[0022] 2) Preparation of polysilicic acid: prepare a sodium silicate solution with a concentration of 0.15 g / L, adjust the pH value of the solution with dilute sulfuric acid, control the pH value of the solution to 1.8, and activate for 30 minutes to obtain polysilicic acid.

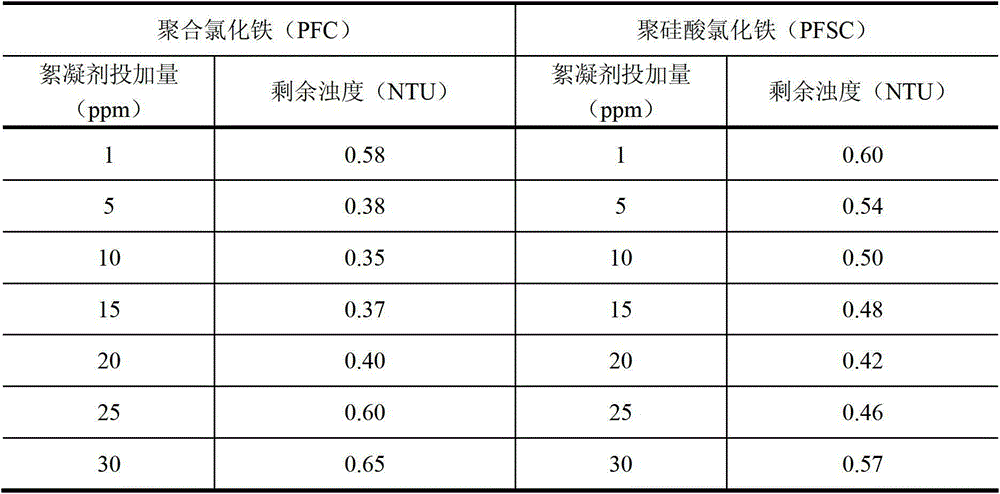

[0023] 3) Preparation of polyferric chloride polysilicate: Mix polyferric chloride and polysilicate a...

Embodiment 2

[0024] Embodiment 2, preparation polysilicate ferric chloride flocculant:

[0025] 1) Preparation of polyferric chloride: Weigh 50g of hematite powder (150 mesh), add 342.47ml of industrial hydrochloric acid with a concentration of 7mol / L to it, react in a water bath heater, control the temperature at 85°C, and stir After reacting for 2.5 hours, filter, adjust the pH value of the solution with sodium hydroxide in a 40°C water bath to control the pH value of the solution to 1.5, react for 30 minutes and then mature for 24 hours to obtain a polyferric chloride solution with a certain degree of polymerization.

[0026] 2) Preparation of polysilicic acid: prepare a sodium silicate solution with a concentration of 0.15 g / L, adjust the pH value of the solution with dilute sulfuric acid, control the pH value of the solution to 2.0, and activate for 30 minutes to obtain polysilicic acid.

[0027] 3) Preparation of polyferric chloride polysilicate: Mix polyferric chloride and polysilic...

Embodiment 3

[0028] Embodiment 3, preparation polysilicate ferric chloride flocculant:

[0029] 1) Preparation of polyferric chloride: Weigh 200g of hematite powder (150 mesh), add 342.47ml of industrial hydrochloric acid with a concentration of 8mol / L, react in a water bath heater, control the temperature at 90°C, and stir After reacting for 3 hours, filter, adjust the pH value of the solution with sodium hydroxide in a water bath at 42°C, and control the pH value of the solution to 1.4, react for 30 minutes and then mature for 24 hours to obtain a polyferric chloride solution with a certain degree of polymerization.

[0030] 2) Preparation of polysilicic acid: prepare a sodium silicate solution with a concentration of 0.15 g / L, adjust the pH value of the solution with dilute sulfuric acid, control the pH value of the solution to 2.0, and activate for 30 minutes to obtain polysilicic acid.

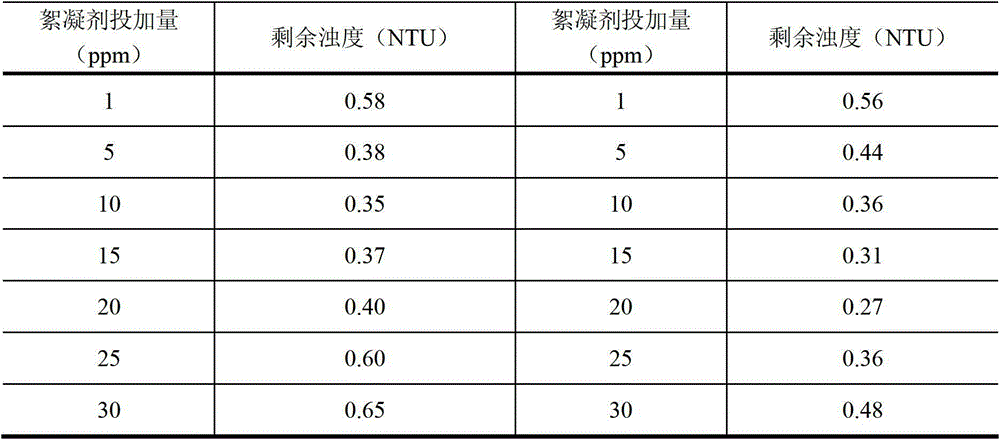

[0031] 3) Preparation of polyferric chloride polysilicate: Mix polyferric chloride and polysilicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com