High-strength and high-stability agricultural anti-explosive ammonium nitrate and preparation method thereof

A high-stability, ammonium nitrate technology, applied in applications, agriculture, fertilizer mixtures, etc., can solve the problems of poor explosion-proof effect, low particle strength of products, large amount of explosion-proof agent added, etc., and achieves safe and convenient production and use, and low production costs. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

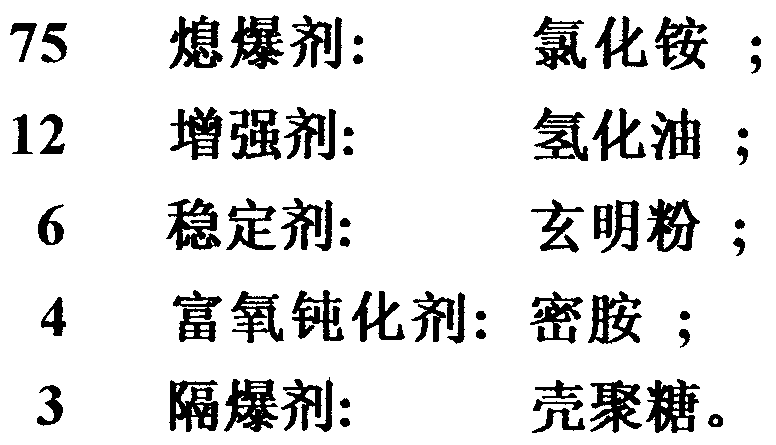

[0024] 1 implement according to the best formula (mass %) as follows:

[0025] 99.4 Ammonium nitrate

[0026] 0.6 Anti-knock agent

[0027] Wherein the component of composite explosion-proof agent is by mass %:

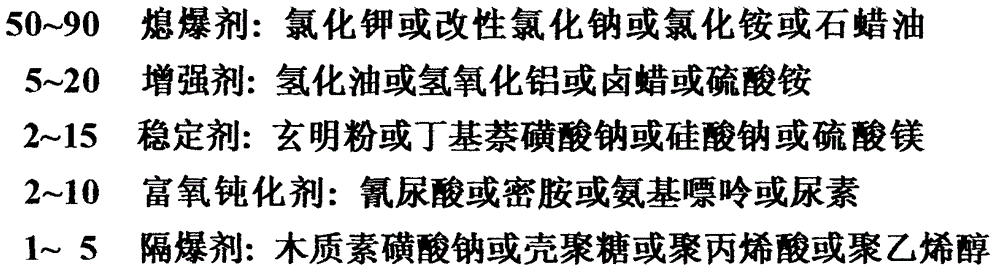

[0028]

[0029] 1.1 Preparation of anti-explosion agent: First, bake 6kg of xuanming powder in an oven at 90-100°C for 4 hours, and pulverize 12kg of hydrogenated oil and 75kg of ammonium chloride in a ball mill with a speed of 40r / min, and the fineness should exceed 425μm80% above; then add the above three qualified raw materials together with 4kg of melamine and 3kg of chitosan into a mixer with a double-layer spiral structure, mix for 30-40 minutes, and then discharge to make a product.

[0030] 1.2 Preparation of the present invention: first in the mixing tank of the ammonium nitrate production line produced by high-tower granulation, inject metering molten ammonium nitrate mother liquor (the mother liquor concentration is 99.0% to 99.5%, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com