Water-soluble temporary camouflage coating and preparation method thereof

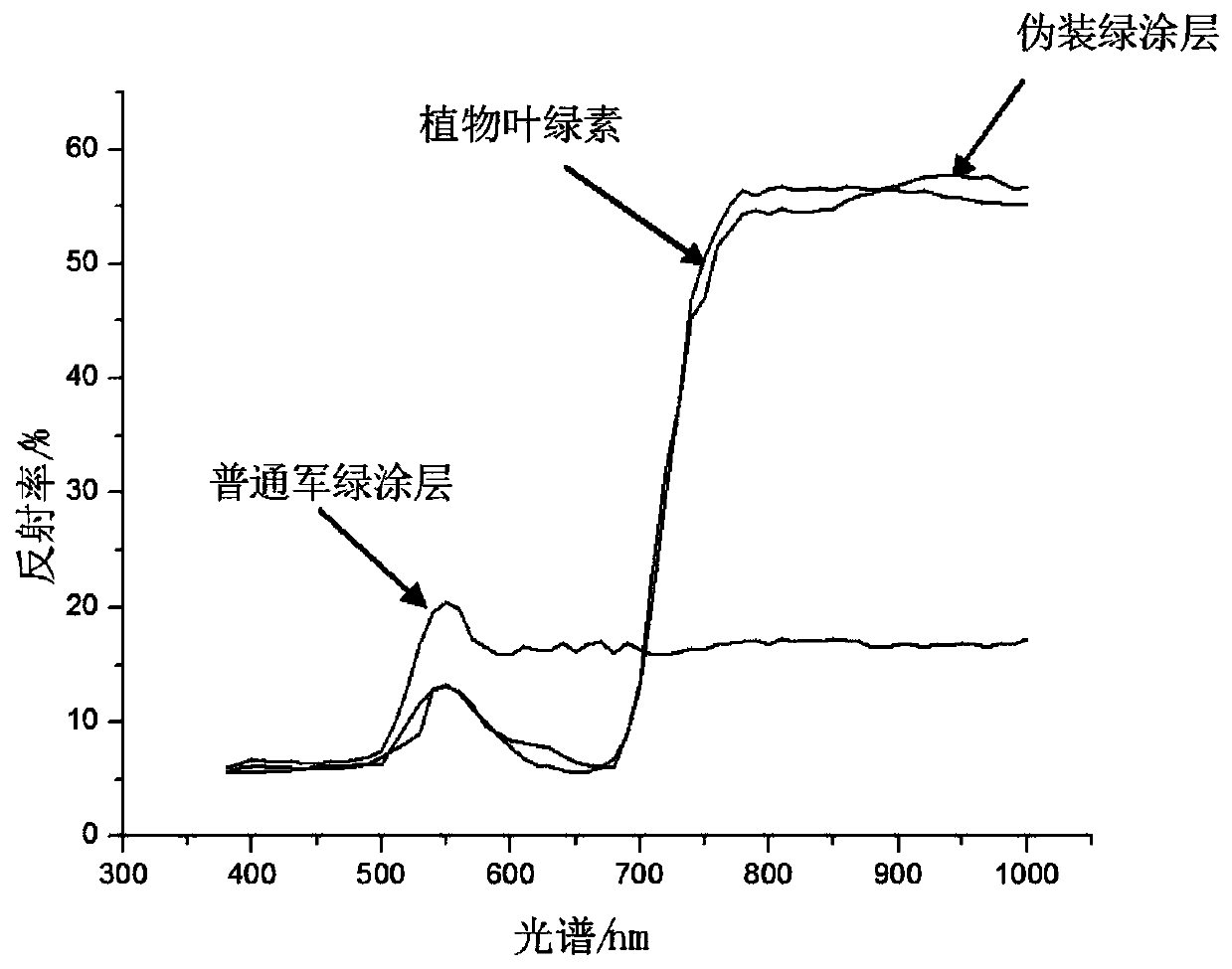

A temporary, water-soluble technology, applied in the direction of camouflage paint, coating, etc., can solve the problems of 79-type water-based camouflage paint, such as complex process, low production speed, and large difference between batches of pigments, so as to meet the requirements of temporary camouflage and production The effect of safe and reliable use and easy coating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 of the present invention provides a water-soluble temporary camouflage camouflage paint, comprising the following components formulated in parts by mass:

[0060] 10-15 parts of water;

[0061] 30-45 parts of water-soluble resin;

[0062] Acrylic emulsion 5-15 parts.

[0063] 0-2 parts of dispersant;

[0064] 0-0.5 parts of fungicide;

[0065] 0.5-3 parts of multifunctional additives;

[0066] 0.2-0.6 part of defoamer;

[0067] 1-5 copies of antifreeze;

[0068] 15-30 parts of various optical camouflage pigments;

[0069] 10-30 parts of filler;

[0070] 0.2-0.8 parts of additives;

[0071] 0.5-2 parts of thickening and anti-settling agent;

[0072] 0.3-0.5 part of defoamer.

[0073] Preferably, the water-soluble temporary camouflage camouflage paint comprises the following components formulated in specific parts by mass:

[0074] 10 parts of water;

[0075] 38 parts of water-soluble resin;

[0076] 8 parts of acrylic emulsion;

[0077] 0.8 par...

Embodiment 2

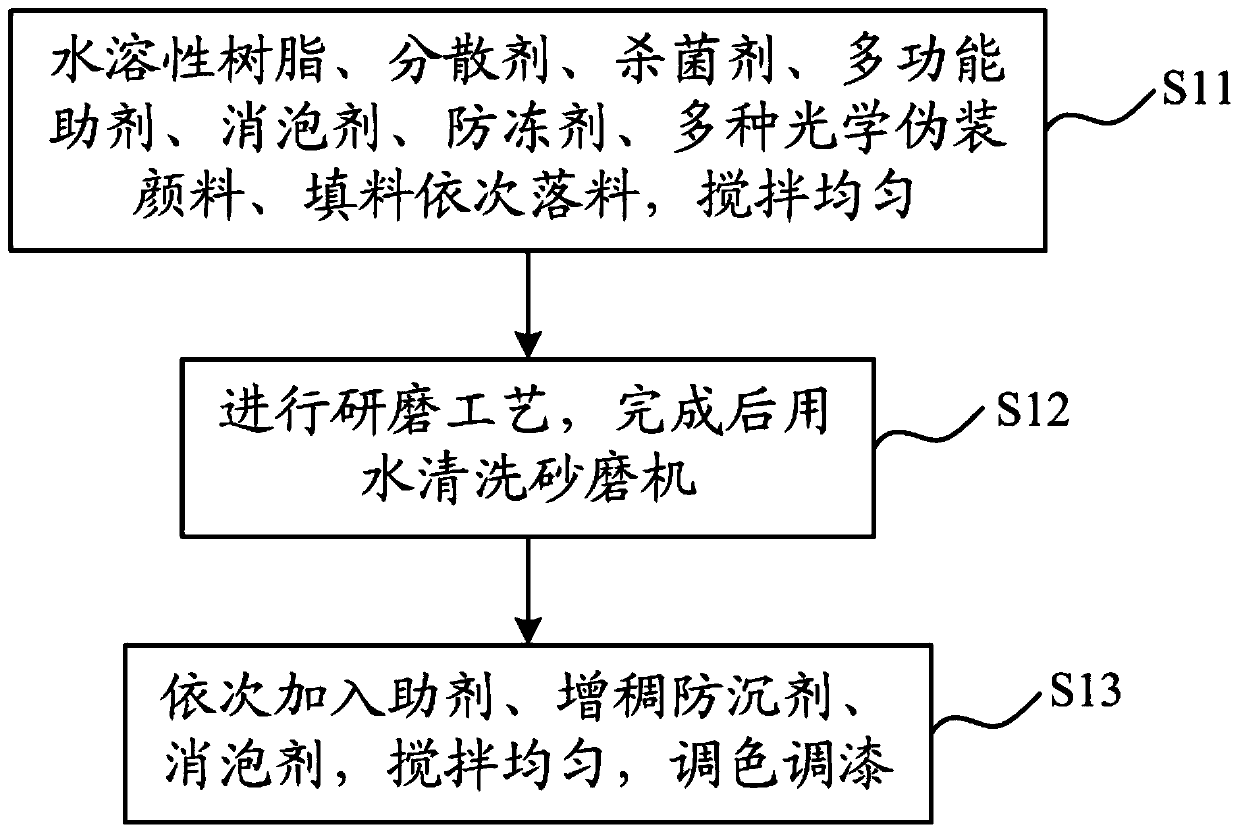

[0089] Embodiment 2 of the present invention provides a kind of preparation method of water-soluble temporary camouflage camouflage paint, comprising the following steps:

[0090] Step S11, water-soluble resin, dispersant, bactericide, multifunctional additive, defoamer, antifreeze, various optical camouflage pigments, and fillers are sequentially blanked and stirred evenly;

[0091] Step S12, perform the grinding process, and wash the sand mill with water after completion;

[0092] Step S13, adding additives, thickening and anti-settling agents, and defoamers in sequence, stirring evenly, and adjusting the paint.

[0093] Preferably, in the grinding process performed in the step S12, the final grinding effect achieves a fineness not greater than 50um.

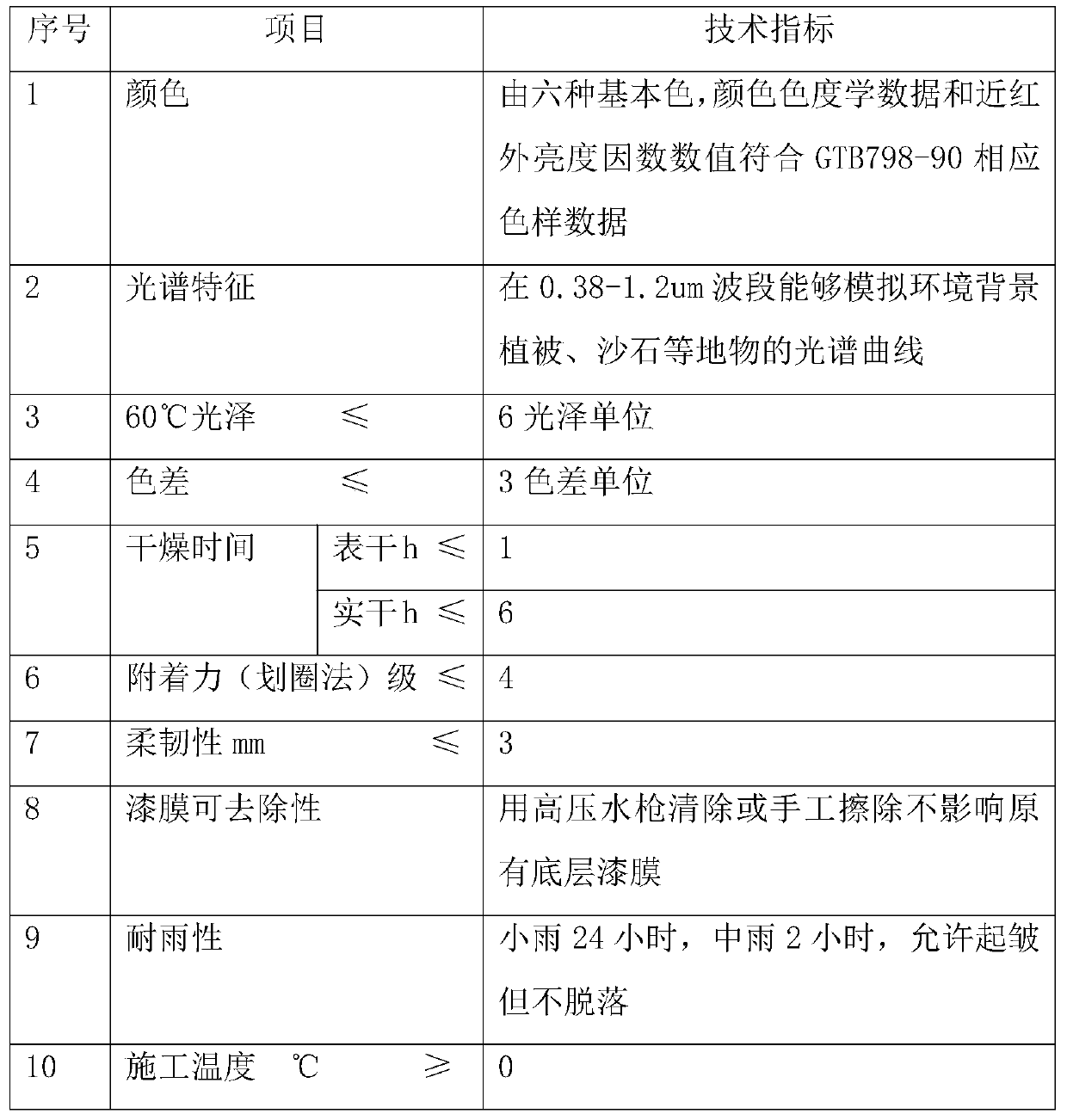

[0094] The performance parameters of the water-soluble temporary camouflage camouflage paint prepared by the preparation method of the above-mentioned water-soluble temporary camouflage camouflage paint are as table 1:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com