Method for preparing burster of double salt of spherical alkali type lead picrate and azide lead

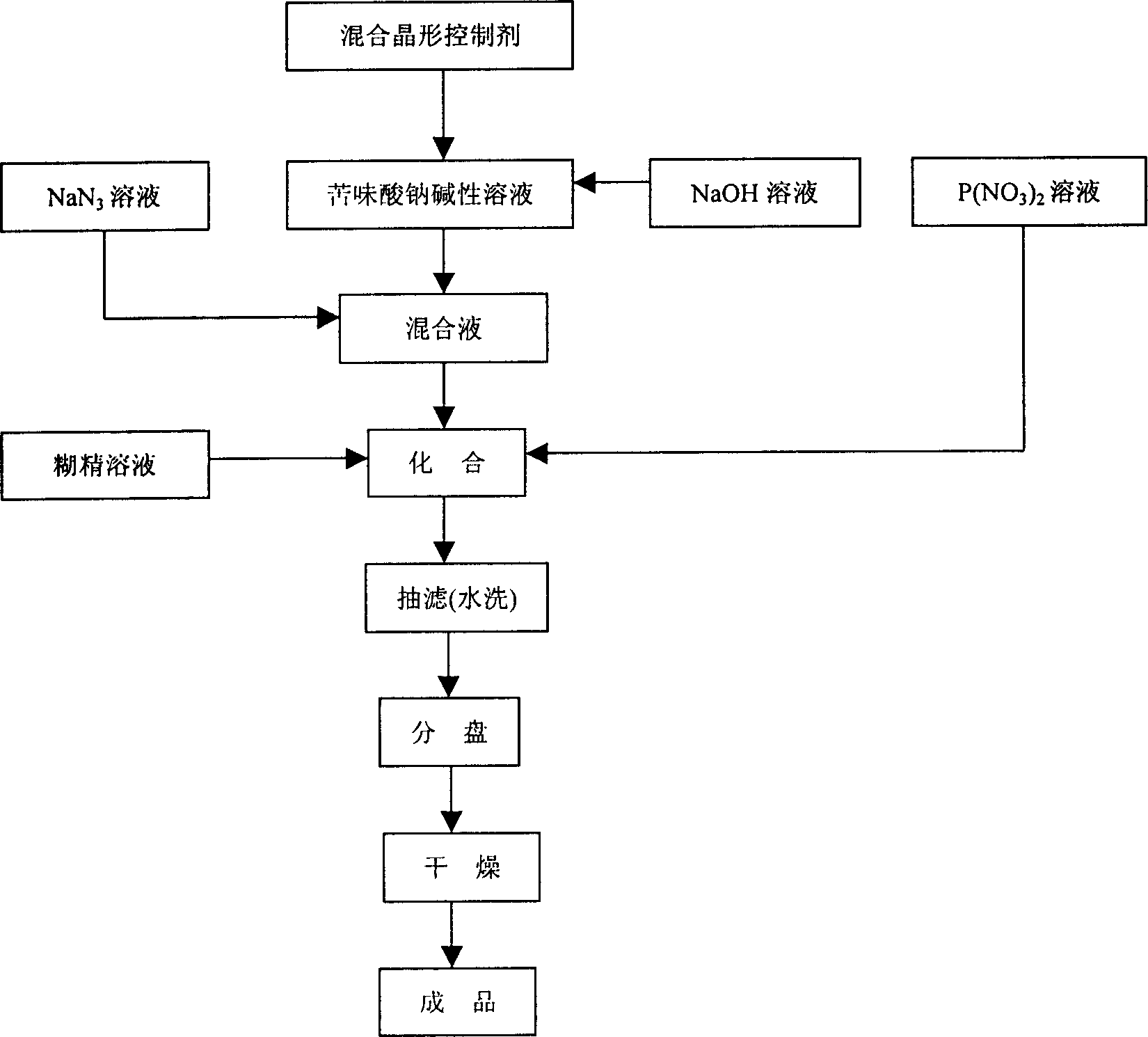

A technology of lead azide and picric acid is applied in the directions of compositions, explosives, and offensive equipment containing nitrated metal organic compounds, which can solve the difficulty in popularization and application of K·D double-salt detonators, disadvantageous detonator assembly safety, and crystallization. It is difficult to control and other problems, so as to achieve the effect of facilitating constant volume metering, stable and reliable product quality, and improving intrinsic safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: in conjunction with the accompanying drawings, first add 29L~33L 18% lead nitrate in the compounder, then add 45L pure water and 5L 5% dextrin solution, as the base liquid, control pH to be 4.0~5.0; 48L sodium picrate alkaline solution (additional NaOH solution) and 11.5L ~ 13.5L 10% sodium azide solution to form a mixed solution; under stirring, add 2.6L of the mixed solution into the compounder at 60°C to 80°C as the advance solution, and then drop it into the mixture at a constant speed after 5 minutes Liquid, the feeding time is 30min~60min, continue to react for 5min after feeding, then lower to about 50°C, siphon the upper mother liquor, add pure water into the compounder, wash twice with water, and discharge. Product false density can reach 2.1g / cm 3 .

Embodiment 2

[0012] Embodiment 2: add 440mL of pure water and 20mL~60mL of 5% dextrin solution in the compounder earlier, with this as bottom liquid, adjust bottom liquid pH to be 4.5~5.0; Then with 18% lead nitrate solution 115mL and mixed solution ( The composition and mixing ratio are the same as in Example 1) 230mL is the dripping liquid; before feeding, add the advance liquid in the ratio of mixed liquid: lead nitrate solution = 4:2 (mL / min) in the compounder, and stop feeding for 5 minutes after 3 minutes. Then add at a uniform speed according to the above-mentioned flow rate ratio, and the reaction completes to separate out the material, and all the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com