A Side Exhaust Pulse Detonation Engine

A pulse detonation engine technology, applied in the field of aero-engines, can solve the problems of long exhaust time, low detonation frequency, airflow blockage, etc., and achieve the effects of rapid response, increased detonation frequency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail.

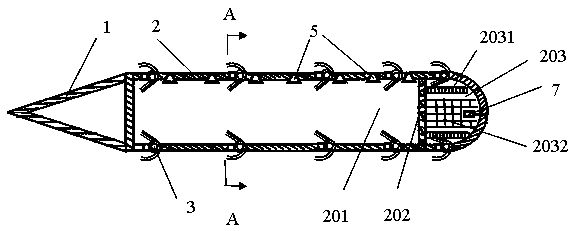

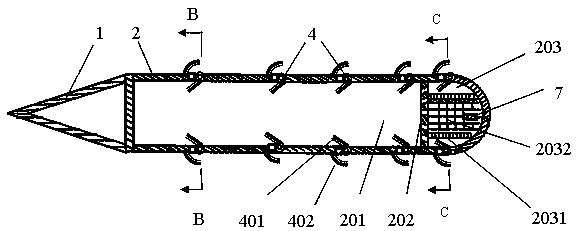

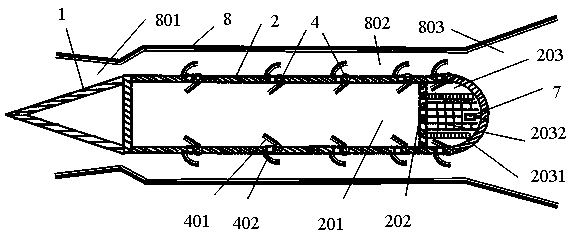

[0027] Such as Figure 1~6 As shown, the pulse detonation engine with side exhaust is mainly composed of the following parts: nose cone 1, detonation tube 2, side intake valve 3, side exhaust valve 4, main fuel nozzle 5, detonation fuel nozzle 6 and igniter 7. The engine equipped with the external duct 8 also includes an air inlet 801, an annular cavity 802 and a tail nozzle 802; both ends of the detonation tube 2 are closed, and the front end cover is a flat end cover, which acts as a thrust wall. The rear end cover is a hemispherical end cover. The detonation tube 2 is divided into a main detonation chamber 201 and an initiation chamber 203 by a sieve plate 202. The main detonation chamber 201 is in front and the detonation chamber 203 is in the rear; There are grooves, and the grooves are evenly distributed along the circumference; the number of grooves is determined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com