Preparation method of sheet-type explosive foil

An explosive foil and sheet technology, applied in blasting barrels, offensive equipment, weapon accessories, etc., can solve problems such as difficulty in mass production, poor product consistency, and complicated assembly process, and achieve mass production, good consistency, and The effect of exempting the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

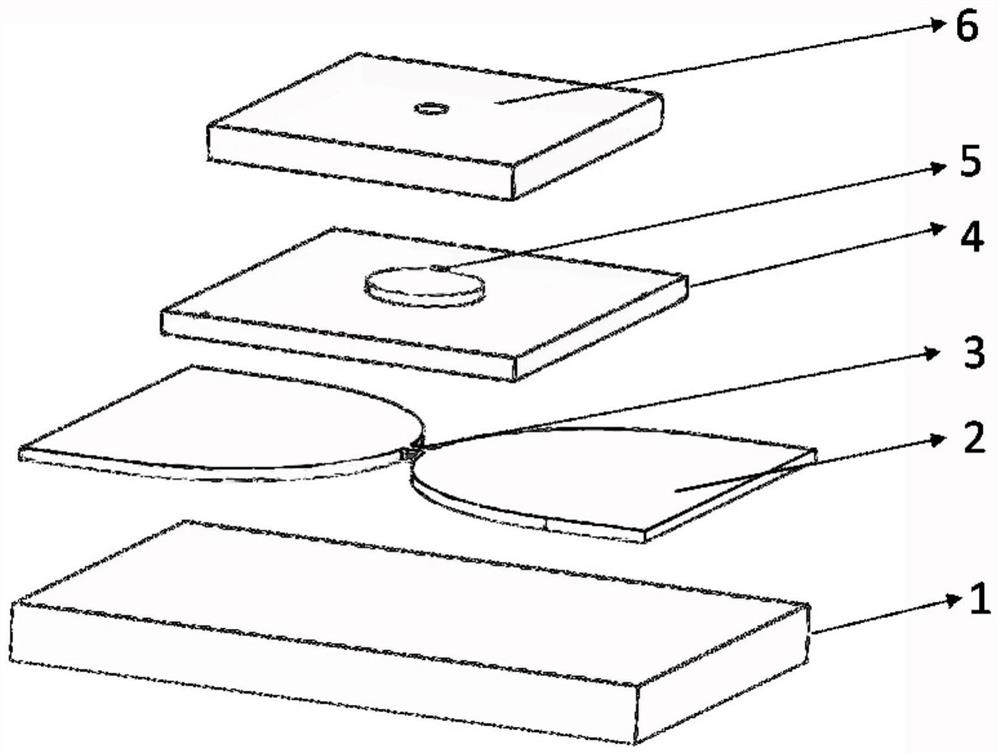

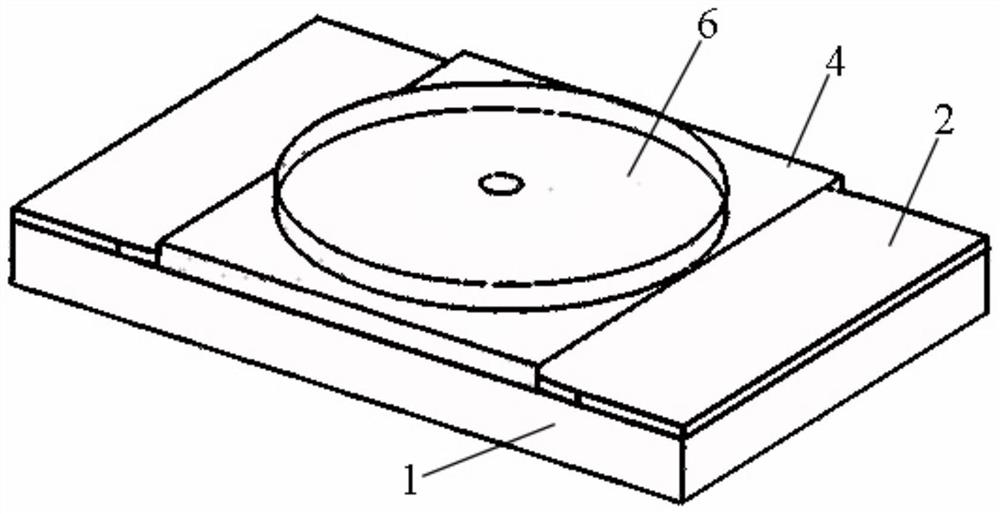

[0037] The preparation steps of the sheet type explosive foil in the present embodiment are as follows:

[0038] a. On a clean ceramic substrate, a WTi layer, a Cu layer and an Au layer are sequentially deposited by physical vapor deposition to form a WTi / Cu / Au composite metal film (the first composite metal film) with a total thickness of 1-8 μm as the transducer Yuan;

[0039] b. Using a photolithography process to etch the WTi / Cu / Au composite metal film (the first composite metal film), prepare an explosive foil pattern array, and form an explosive foil pad area and an explosive foil bridge area;

[0040] c. On the WTi / Cu / Au composite metal film (the first composite metal film), a Parylene film with a thickness of 5-50 μm is deposited by chemical vapor deposition, and then a total thickness of 0.2 is deposited on the Parylene film by physical vapor deposition. ~4μm WTi / Cu / Au composite metal film (the second composite metal film), forming a polymer / metal composite flying sh...

Embodiment 2

[0047] The preparation steps of the sheet type explosive foil in the present embodiment are as follows:

[0048] a. On a clean glass substrate, a NiCr layer, an Al layer and an Au layer are sequentially deposited by physical vapor deposition to form a NiCr / Al / Au composite metal film (the first composite metal film) with a total thickness of 1-8 μm as an energy transducer Yuan;

[0049] b. Using a photolithography process, etch the NiCr / Al / Au composite metal film (the first composite metal film), prepare an explosive foil pattern array, and form an explosive foil pad area and an explosive foil bridge area;

[0050] c. On the NiCr / Al / Au composite metal film (the first composite metal film), a polyimide film with a thickness of 5 to 50 μm is pressed by hot pressing, and then a physical vapor deposition method is used on the polyimide film Depositing a NiCr / Al / Au composite metal film (second composite metal film) with a total thickness of 0.2-4 μm to form a polymer / metal composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com