Nicosulfuron atrazine oil suspension with methyl oleate as dispersing medium and preparation method thereof

A technology of methyl oleate and dispersing medium, applied in the field of broad-spectrum herbicidal preparations, can solve the problems of high viscosity, hinder the development and utilization of suspending agent, poor self-dispersion, etc. effect of ripening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

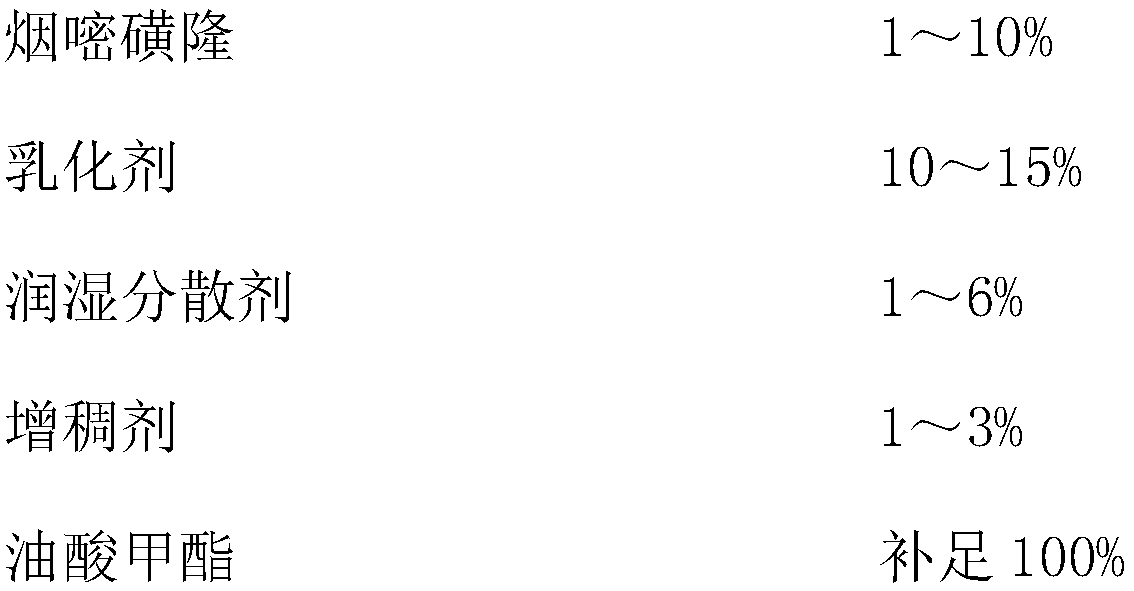

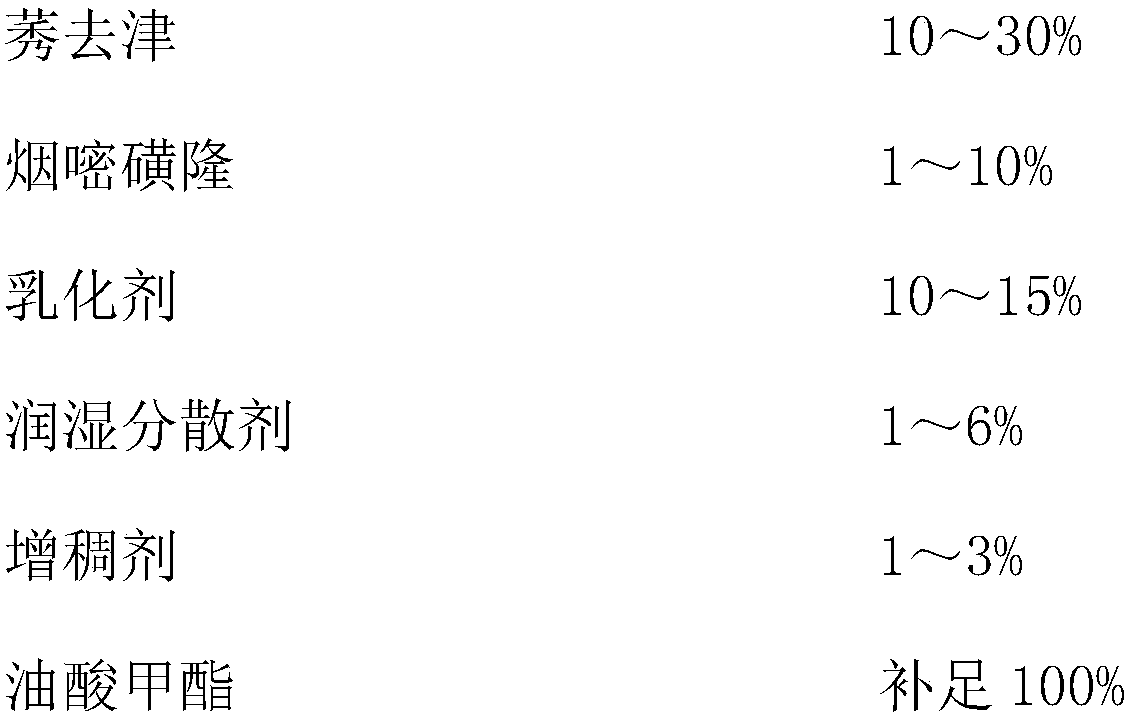

Image

Examples

Embodiment 1

[0029] 24% Nicotin·Atrazine dispersible oil suspension

[0030] The content of each component (by weight) is 20% for atrazine technical, 4% for nicosulfuron, and 2% for sulfate dispersant SD-208 (Shanghai Shida Polymer Materials Co., Ltd.); Nongru 500# 4%, NP-10 nonylphenol polyoxyethylene ether phosphate emulsifier 8% (Shanghai Shida Polymer Materials Co., Ltd.), thickener organic bentonite 2%, and methyl oleate to make up to 100%.

[0031] The preparation process is:

[0032] Step 1: Add all the emulsifiers to methyl oleate, mix and stir evenly, carry out continuous sanding with a horizontal sand mill, control the sanding temperature at 0-40℃, and stop sanding when the particle size reaches 1~5μm. 24% Nicotin·Atrazine dispersible oil suspension concentrate;

[0033] Step 2: Dissolve nicosulfuron, atrazine technical and dispersant in the above 24% nicocil·atrazine dispersible oil suspension agent according to the formula ratio, so that the materials are all wetted, and then added in...

Embodiment 2

[0037] Example 2 27% Nicotin·Atrazine dispersible oil suspension

[0038] The content of each component (by weight) is 20% of atrazine technical, 7% of nicosulfuron, 2% of sulfate dispersant SD-208 (Shanghai Shida Polymer Material Co., Ltd.); Styryl phenol Polyoxyethylene polyoxypropylene ether 4%, polymer EO-PO block copolymer 8%, thickener hydroxyethyl cellulose 2%, and methyl oleate to make up to 100%. Specific preparation process:

[0039] Step 1: Add all the emulsifiers to methyl oleate, mix and stir evenly, carry out continuous sanding with a horizontal sand mill, control the sanding temperature at 0-40℃, and stop sanding when the particle size reaches 1~5μm. 27% Nicotin·Atrazine dispersible oil suspension concentrate;

[0040] Step 2: Dissolve nicosulfuron, atrazine technical and dispersant in the above 24% nicocil·atrazine dispersible oil suspension agent according to the formula ratio, so that the materials are all wetted, and then added in the sand mill Appropriate amoun...

Embodiment 3

[0043] Example 3 23% Nicotin·Atrazine dispersible oil suspension

[0044] The content of each component (by weight) is 20% of atrazine technical, 3% of nicosulfuron, 2% of sulfate dispersant SD-208 (Shanghai Shida Polymer Material Co., Ltd.); Span-60 4%, AEO-9 fatty alcohol polyoxyethylene ether 8%, thickener methyl cellulose or polyvinyl alcohol 2%, and methyl oleate to make up to 100%.

[0045] Specific preparation:

[0046] Step 1: Add all the emulsifiers to methyl oleate, mix and stir evenly, carry out continuous sanding with a horizontal sand mill, control the sanding temperature at 0-40℃, and stop sanding when the particle size reaches 1~5μm. 23% Nicotin·Atrazine dispersible oil suspension concentrate;

[0047] Step 2: Dissolve nicosulfuron, atrazine technical and dispersant in the above 24% nicocil·atrazine dispersible oil suspension agent according to the formula ratio, so that the materials are all wetted, and then added in the sand mill Appropriate amount of zirconium bead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com