Natural composite amino acid raw material preparation method and natural composite amino acid raw material

A compound amino acid and raw material technology is applied in the field of preparation of natural compound amino acid raw materials, and achieves the effects of large sample loading, low cost, and simple and reliable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

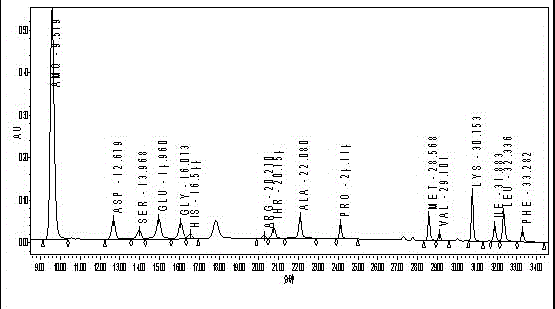

Image

Examples

Embodiment 1

[0030] The preparation method of this natural compound amino acid raw material of the present invention comprises the steps:

[0031]a. Take 50kg of frozen fresh pig brain, soak it in water to thaw naturally, then wash it with water, then add 100kg of purified water and use a colloid mill to homogenize it for 15 minutes, pour the slurry obtained from the homogenization into an extraction tank, heat it to 80°C, keep it warm for 15 minutes, and then Add 250 ml of concentrated hydrochloric acid with a concentration of 12 mol / L, stir evenly, cool to 40°C, centrifuge at a speed of 3800r / min, remove the upper emulsion, collect the precipitate, and obtain 2.3kg of precipitated cerebroprotein;

[0032] b. Add 3000ml of sulfuric acid with a concentration of 18.4mol / L to the precipitated protein obtained in step a for hydrolysis to make a sulfuric acid solution with a concentration of 12mol / L, heat to 121°C, hydrolyze for 8 hours, and then dilute with water 10 times the weight ratio , u...

Embodiment 2

[0038] a. Take 50kg of frozen fresh pig brain, soak it in water to thaw naturally, then wash it with water, then add 200kg of purified water and use a colloid mill to homogenize it for 15 minutes, pour the slurry obtained from the homogenization into an extraction tank, heat it to 70°C and keep it warm for 10 minutes, then Add 100 ml of concentrated hydrochloric acid with a concentration of 12mol / L, stir well, cool to 10°C, and then centrifuge at a speed of 3000r / min, then remove the upper emulsion, collect the precipitate, and obtain 2.4kg of precipitated cerebroprotein;

[0039] b. Add 2500ml of sulfuric acid with a concentration of 18.4mol / L to the precipitated protein obtained in step a for hydrolysis to make a sulfuric acid solution with a concentration of 6mol / L, heat to 110°C, hydrolyze for 6 hours, and then dilute with water with a weight ratio of 5 times , use calcium hydroxide solution to adjust the pH value to 8 (calcium hydroxide solution used is obtained by dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com