Water-soluble pore-forming agent used for bulky porous granular ammonium nitrate with high oil absorptivity

A technology of porous granular ammonium nitrate and pore-forming agent, which is applied in the directions of non-explosive/non-thermal agent components, offensive equipment, explosives, etc. Simple, white appearance, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1 implement according to the following optimal composition (mass %):

[0029] 50 Foaming agent: Xuanming powder

[0030] 30 Penetrant: sodium methylene dinaphthalene sulfonate

[0031] 10 Strengthening agent: aluminum sulfate

[0032] 4 Dispersant: sodium dodecylbenzenesulfonate

[0033] 4 heat resistant agent: salicylic acid

[0034] 2 Solubilizer: fatty alcohol polyoxyethylene ether

[0035] Preparation of the present invention: 40 g of salicylic acid, 40 g of sodium dodecylbenzene sulfonate and 20 g of fatty alcohol polyoxyethylene ether are dried in an oven at 60-70°C for 4 hours, and then 300 g of sodium methylene dinaphthalene sulfonate 100g of aluminum sulfate and 500g of xuanming powder with a fineness of 250 μm sieve of 95% after crushing are added together in a mixer with double-layer double-helix structure, mixed for 25 to 30 minutes, and the product of the present invention is produced after discharging.

[0036] Utilize the present invention, adopt the...

PUM

| Property | Measurement | Unit |

|---|---|---|

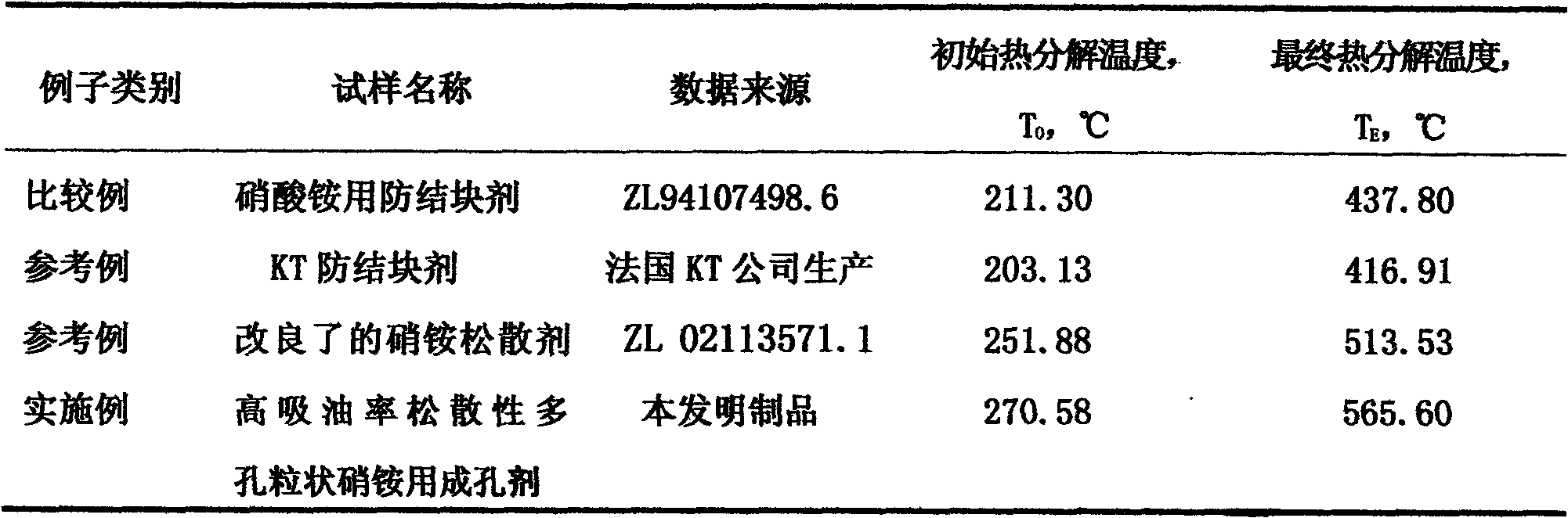

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com