Screwdriver aid

An auxiliary and screwdriver technology, applied in screwdrivers, wrenches, wrenches, etc., can solve the problem that the operator cannot start, and achieve the effect of simple structure, high efficiency, and enlarged performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

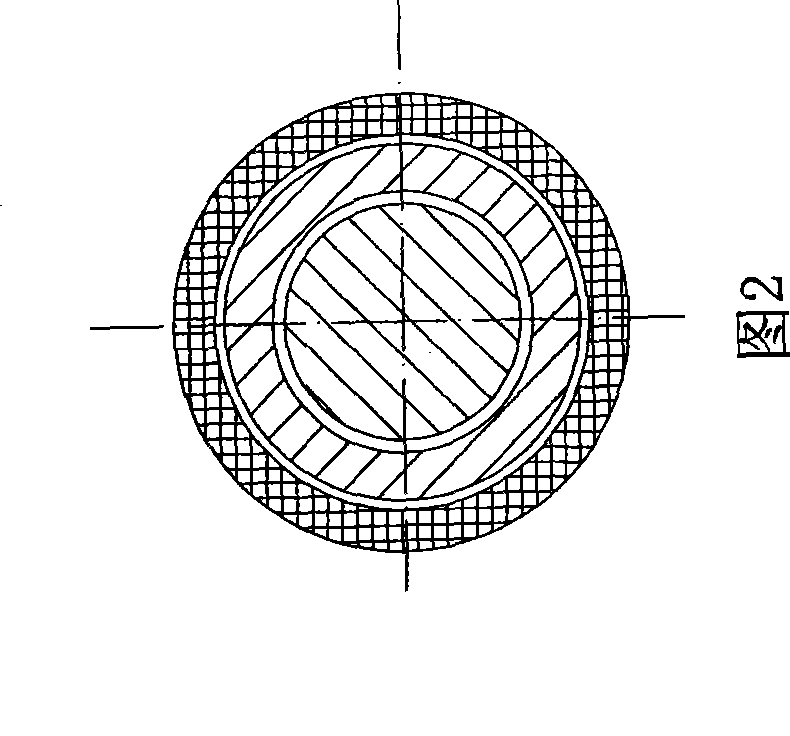

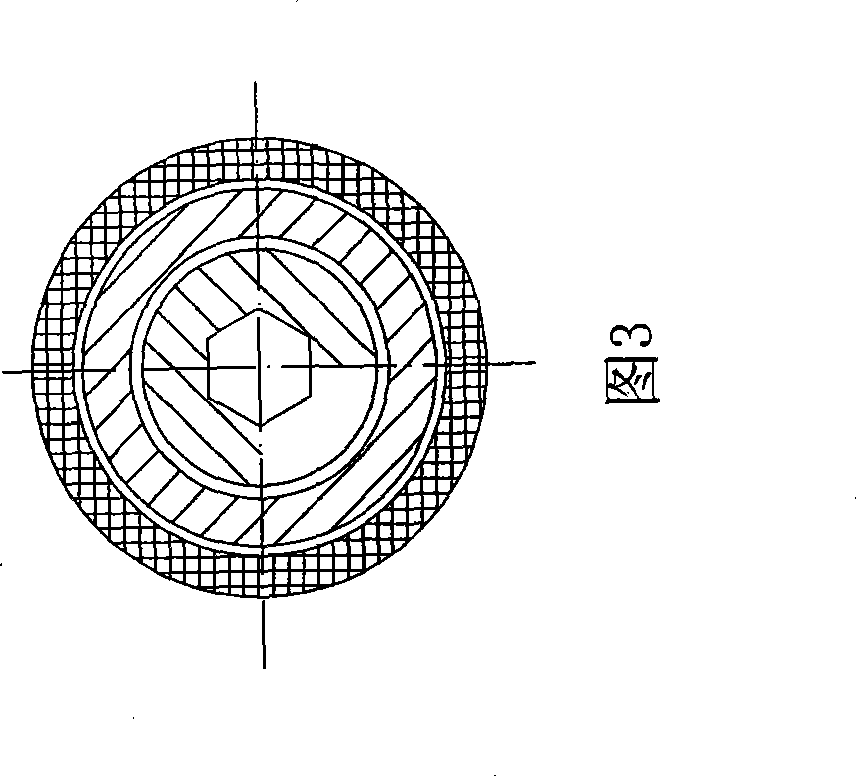

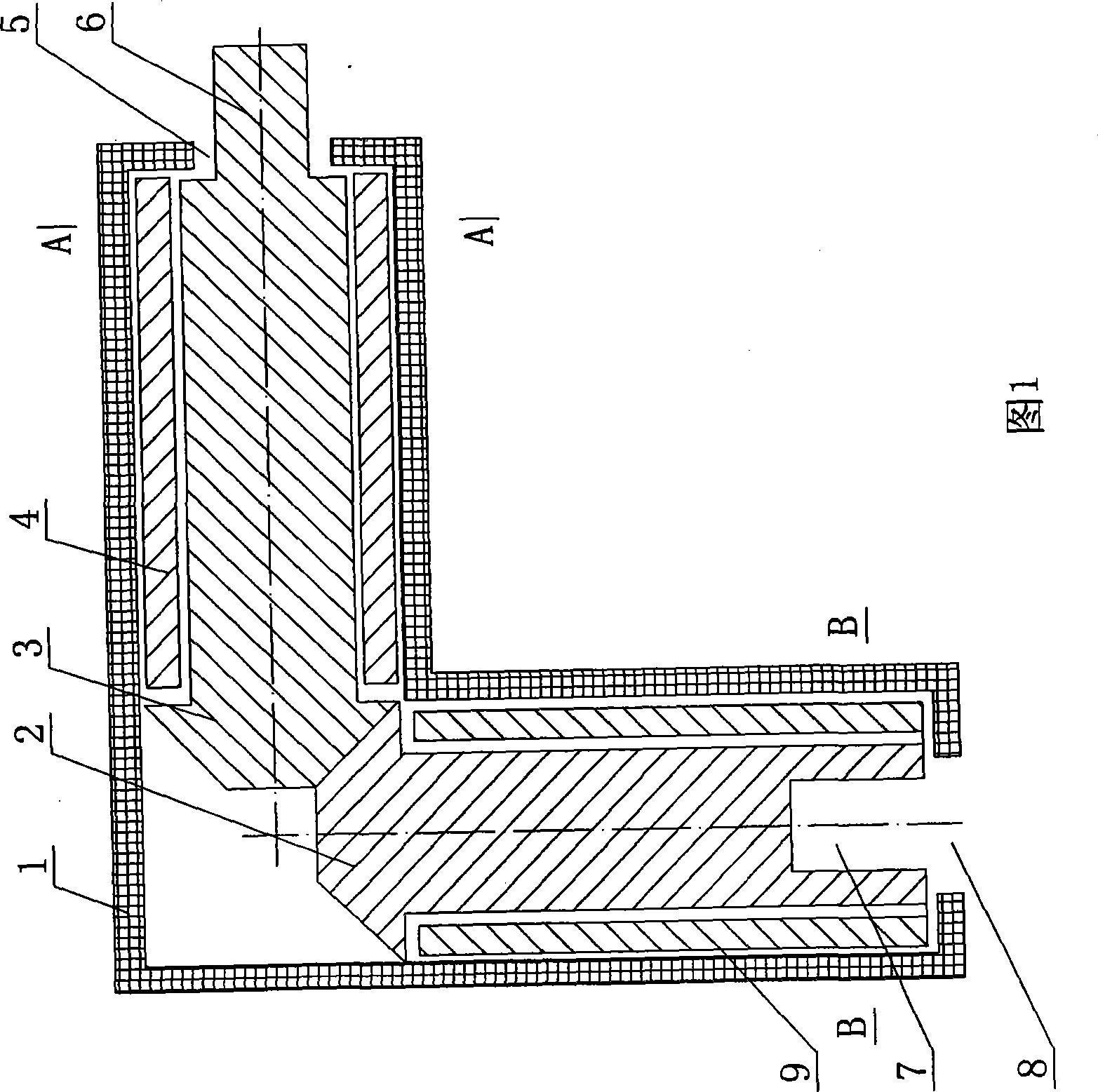

[0022] Referring to accompanying drawing 1~3, this embodiment of screwdriver auxiliary device of the present invention draws material pipe diameter and is ¢ 16mm, and pipe wall thickness is the stainless steel pipe profile of 2mm to make square-shaped sleeve 1, makes sleeve 1 both sides cylinder body perpendicular intersect, There is a first through hole 5 at the bottom of the cylinder at both ends of the cylinder, the diameter of which is ¢10mm. The bottom of the other end tube has a second through hole 8, and the aperture is also ¢10mm. The first bevel gear 3 and the second bevel gear 2 are arranged in transmission connection along the inner cylinder cavity of the sleeve 1 . Wherein the outer end of the wheel shaft of the first bevel gear 3 coaxially extends a connecting boss 6 out of the first through hole 5 of the sleeve 1 . The cross-section of the connecting boss 6 is hexagonal; the outer end of the wheel shaft of the second bevel gear 2 is coaxially provided with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com