Gel phase-change material as well as preparation method and application method thereof

A gel phase and gel technology, which is applied in the field of gel phase change materials and their preparation, can solve the problems of no mature phase change material products, etc., and achieve the effects of low cost, simple preparation process, and long cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

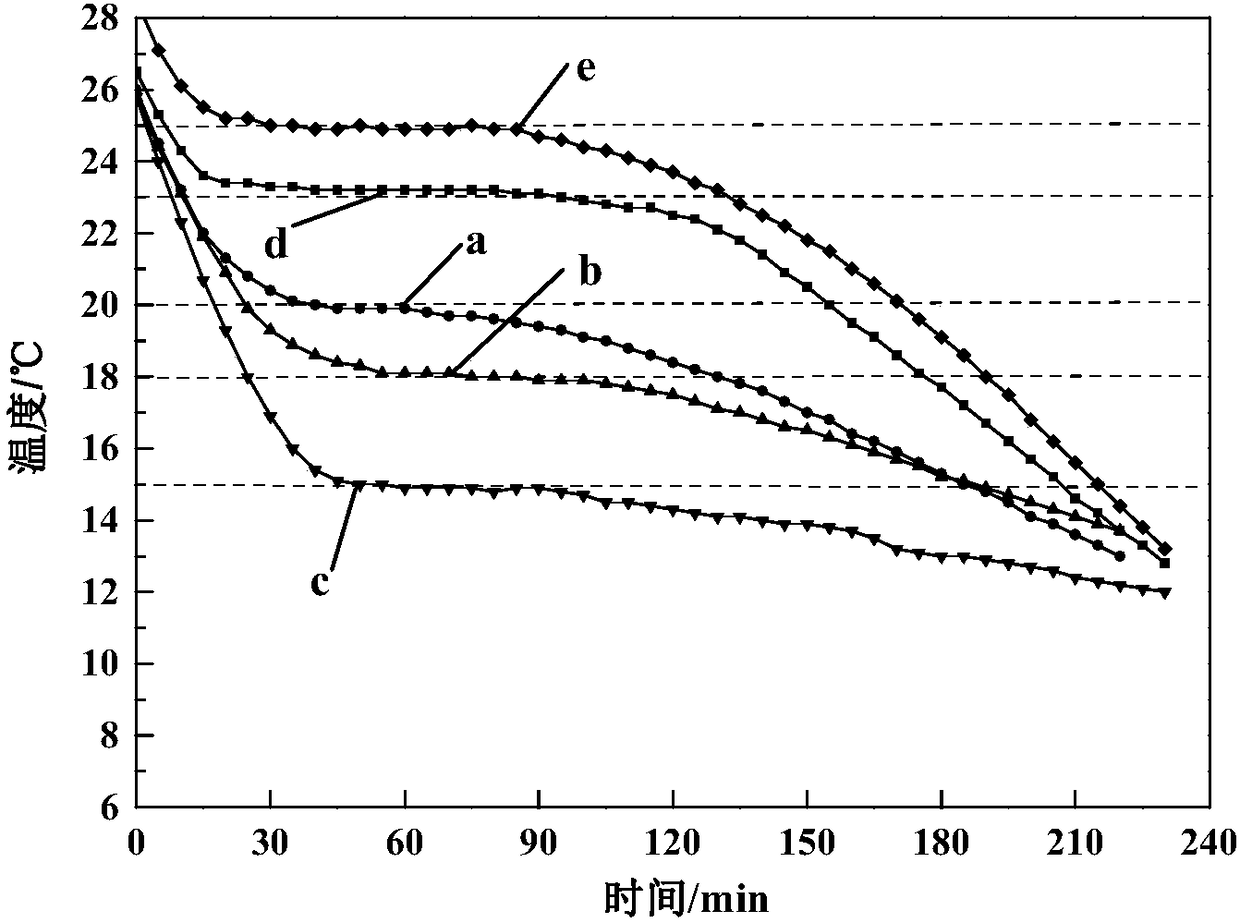

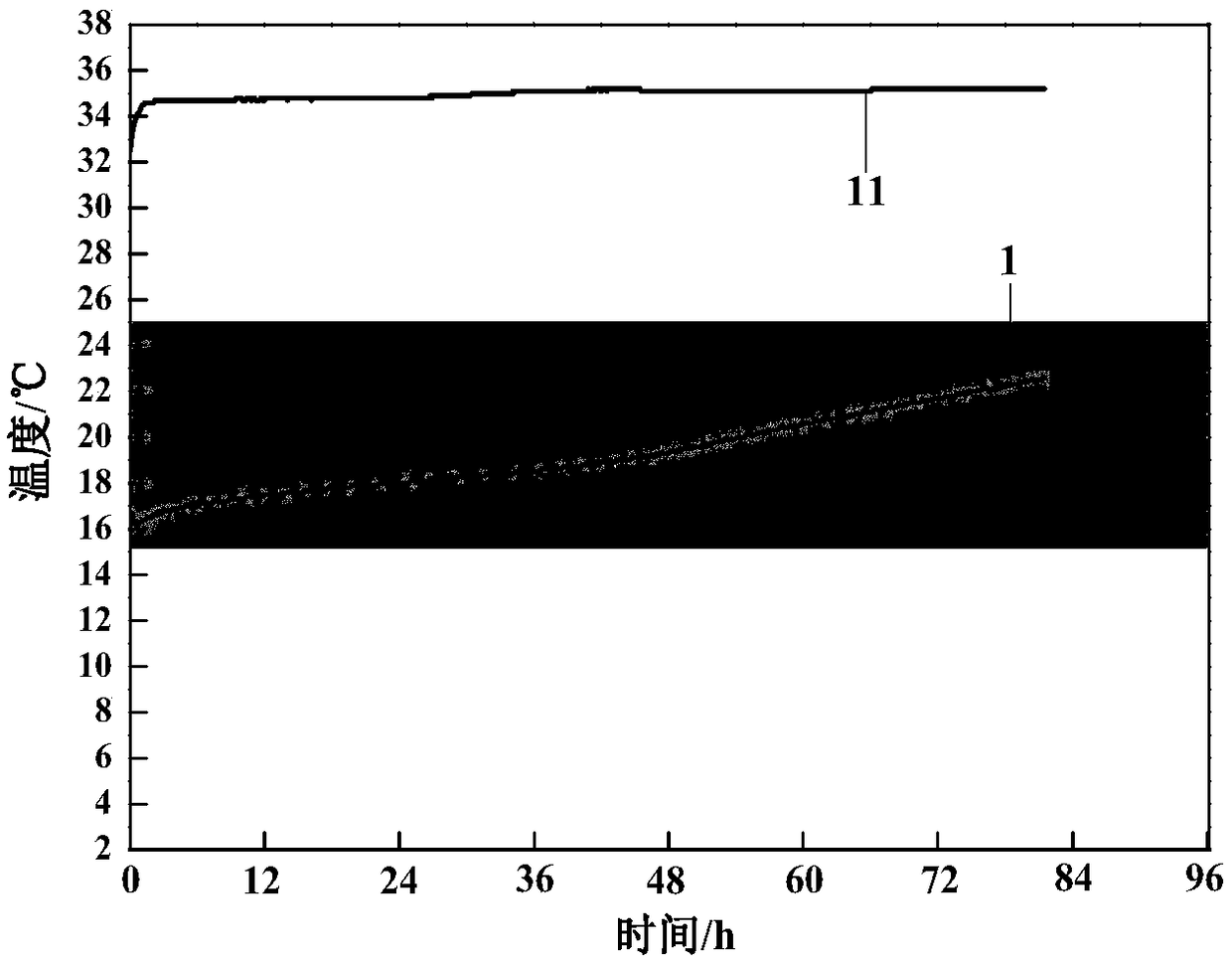

Examples

Embodiment 1

[0053] The gel phase change material in this embodiment includes the following components in terms of mass percentage: 36.61% sodium sulfate; 7.40% sodium chloride; 1.85% ammonium chloride; 2.77% thickener; 3.24% borax; agent 0.14%; white carbon black 1.39%; pure water 46.60% (resistivity at 25°C is 10MΩ·cm). Wherein, the thickener includes sodium polyacrylate; the crystal form changing agent includes sodium hexametaphosphate.

[0054] The preparation method of the above-mentioned gel phase change material comprises the following steps:

[0055] S1, take by weighing 198g sodium sulfate, 40g sodium chloride, 10g ammonium chloride, 15g sodium polyacrylate, 17.5g borax, 0.75g sodium hexametaphosphate, 7.5g white carbon black standby; Wherein, described sodium chloride and chlorine The mass ratio of ammonium chloride is preferably 4:1;

[0056] S2. Weigh 252g of pure water, and divide the water into two parts: 200g and 52g; it should be noted that the weighted amounts of the abo...

Embodiment 2

[0070] The only difference between this example and Example 1 is that the gel phase change material in this example includes the following components in terms of mass percentage: 36.28% sodium sulfate; 7.33% sodium chloride; 1.83% ammonium chloride Thickener 3.66%; Borax 3.21%; Crystal form changing agent 0.13%; White carbon black 1.37%; Wherein, the thickener includes sodium carboxymethylcellulose; and the crystal form changing agent includes sodium hexametaphosphate.

[0071] The preparation method of the above-mentioned gel phase change material comprises the following steps:

[0072] S1, take by weighing 196g sodium sulfate, 40g sodium chloride, 10g ammonium chloride, 20g sodium carboxymethylcellulose, 17.3g borax, 0.7g sodium hexametaphosphate, 7.4g white carbon black for subsequent use;

[0073] S2, take by weighing 249g pure water, and this moisture is divided into 200g (accounting for 80.3% of the total weight of pure water) and 49g two parts;

[0074] S3, 200g of pu...

Embodiment 3

[0081] The only difference between this example and Example 1 is that the gel phase change material in this example includes the following components in terms of mass percentage: 36.23% sodium sulfate; 8.12% sodium chloride; 2.03% ammonium chloride Thickener 2.77%; Borax 3.23%; Crystal form changing agent 0.14%; White carbon black 1.57%; Wherein, the thickener includes sodium carboxymethyl cellulose; the crystal form changing agent includes a mixture of sodium hexametaphosphate and sodium tripolyphosphate.

[0082] The preparation method of the above-mentioned gel phase change material comprises the following steps:

[0083] S1, take by weighing 196g sodium sulfate, 44g sodium chloride, 11g ammonium chloride, 15g sodium carboxymethylcellulose, 17.4g borax, 0.76g the mixture of sodium hexametaphosphate and sodium tripolyphosphate, 8.5g white carbon black standby ;

[0084] S2, take by weighing 248g pure water, and this moisture is divided into 200g (accounting for 80.6% of pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com