Large-granular boric acid, continuously cooling recrystallization preparation process and continuously cooling recrystallization preparation method thereof

A preparation process and large particle technology, applied in the direction of boron oxides, etc., can solve the problems of palliatives but not the root cause, and cannot completely eliminate the problem of floating crystals, and achieve good fluidity, eliminate floating crystals, and reduce floating crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

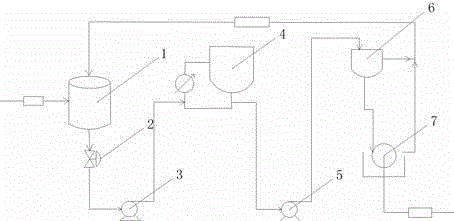

Embodiment 1

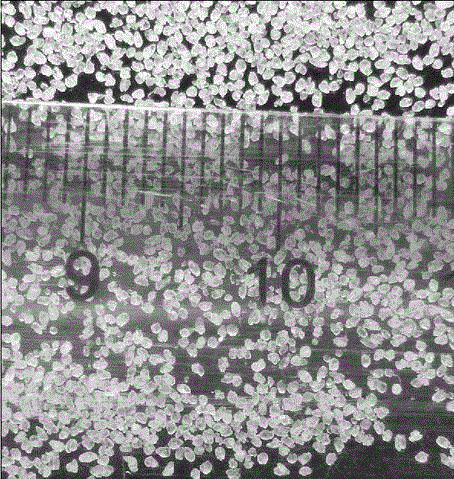

[0028] A preparation process for continuous cooling and recrystallization of large boric acid particles. Boron-containing waste water or powdery boric acid crude product and deionized water are mixed according to the ratio of mass ratio (10-35): 100, and 10-1000ppm of surface tension changing agent is added to obtain Mixture, then raise the temperature and stir the mixture until it is completely dissolved, and then lower the temperature for the first time. When the temperature reaches 1-3°C before the crystallization point, add boric acid seeds with a particle size of 0.1-0.3mm, and lower the temperature for the second time to 10-3°C. The mother liquor of continuous crystallization is obtained at 20°C, and the mother liquor is preheated to 50-90°C and then undergoes three processes of cyclic crystallization, centrifugation and washing, and finally dried to obtain large particle boric acid products, and the cycle crystallization time is controlled at 2~8h;

[0029] Wherein the a...

Embodiment 2

[0031] Mix the concentrated boric acid waste liquid and deionized water, wherein the mass ratio between boric acid waste liquid and deionized water is 15.6:100, heat up to 50-90°C and stir to dissolve completely, then add 10-1000ppm sodium sulfate decahydrate , and then slowly lower the temperature at a rate of 2-10°C / h. When the temperature of the solution reaches 1-3°C before the crystallization point of boric acid, add boric acid seed crystals with a particle size of 0.1-0.3mm, and the amount added is the mass of boric acid waste liquid. 10‰, continue to cool down, the cooling rate is 5-15°C / h, until the temperature drops to 15°C to obtain the mother liquor, preheat the mother liquor to 50-90°C, and then carry out continuous crystallization, and control the crystal growth (crystallization) time at 4h, Then centrifuge, wash, and dry to obtain uniform boric acid particle products. The centrifuge and washing liquid are recycled after being concentrated. The crystallization syst...

Embodiment 3

[0033] Mix crude boric acid powder and deionized water, wherein the mass ratio between crude boric acid powder and deionized water is 35:100, heat up to 50-90°C and stir to dissolve completely, then add 10-600ppm of potassium sulfate, slowly cool down , the cooling rate is 2-10°C / h, when the temperature of the solution reaches 1-3°C before the crystallization point of boric acid, add boric acid seed crystals, the particle size is 0.1-0.3mm, and the amount added is 1‰ of the mass of the crude product of powdery boric acid, Continue to cool down at a cooling rate of 5-15°C / h until the temperature drops to 10°C to obtain the mother liquor. Preheat the mother liquor to 50-90°C for continuous crystallization, and control the crystal growth (crystallization) time to 6 hours, followed by centrifugation , washing, and drying to obtain uniform boric acid particle products, and the centrifuge and washing liquid are recycled after being concentrated. The crystallization system uses an ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com