Multi-functional half-white brightness tin-plated additive

An additive and multi-functional technology, applied in the field of tin plating, can solve the problems of insufficient thickness of the tin plating layer, weak bonding force, narrow bright area, etc., achieve excellent solderability and oxidation resistance, improve the deterioration of plating solution, bright area wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A multifunctional semi-white bright tin plating additive formulated from the following raw materials:

[0044] 15 parts of methanol, 35 parts of dipropylene glycol methyl ether, 0.5 parts of formaldehyde, 10 parts of 2-naphthol polyoxyethylene (12) ether, 2.5 parts of hydroquinone, 2.5 parts of gelatin, 0.5 parts of sodium isooctyl sulfate, quercetin 0.2 parts of diaminodiphenylmethane, 0.1 parts of diaminodiphenylmethane, 0.1 parts of diethylenetriaminepentaacetic acid, 0.05 parts of hydroxylamine sulfate, 1 part of methanesulfonic acid, 0.05 parts of polyethyleneimine, 32.5 parts of deionized water

[0045] test:

[0046] The pre-prepared Example 1 was slowly added to the base liquid of stannous methanesulfonate under stirring condition, the addition amount was 2-4mL / L, after stirring evenly, the Hull cell test was used.

[0047] Hull cell conditions: θ is 45°, current 1A, temperature 38-45°C, time 45-85 seconds

[0048] Test Results:

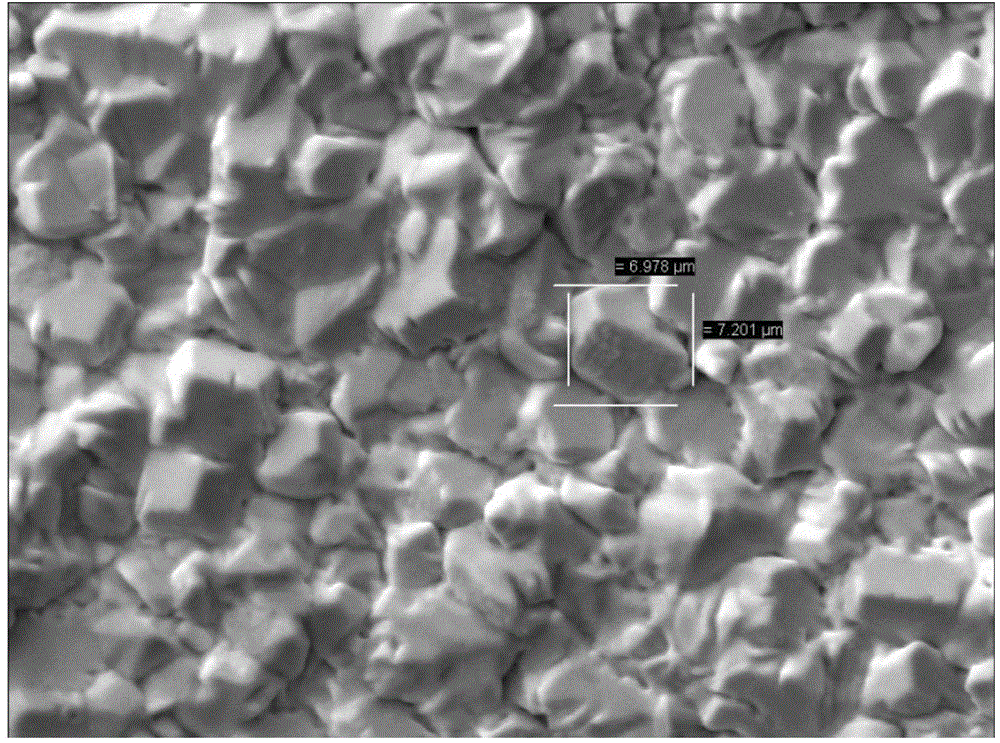

[0049] Hass sheet result sho...

Embodiment example 2

[0053] A multifunctional semi-white bright tin plating additive formulated from the following raw materials:

[0054] 8 parts of isopropanol, 40 parts of diethylene glycol butyl ether, 0.2 parts of 2-naphthaldehyde, 12 parts of bisphenol A polyoxyethylene (15) ether, 2 parts of resorcinol, 1.5 parts of gelatin, sulfosuccinic acid 1 part of sodium salt of dibutyl ester, 0.3 part of basic yellow, 0.1 part of diaminodiphenylmethane, 0.1 part of ethylenediaminetetraacetic acid, 0.1% of hydrazine hydrate, 0.8 part of methanesulfonic acid, 0.05 part of polyacrylamide, deionized 33.85 parts of water.

[0055] test:

[0056] Slowly add the pre-prepared multi-functional semi-white bright tin plating additive into the base liquid of stannous methanesulfonate under stirring condition, the addition amount is 2-4mL / L, after stirring evenly, use the Hull cell test .

[0057] Hull cell conditions: θ is 45°, current is 1A, temperature is 38-45°C, time is 45-85 seconds.

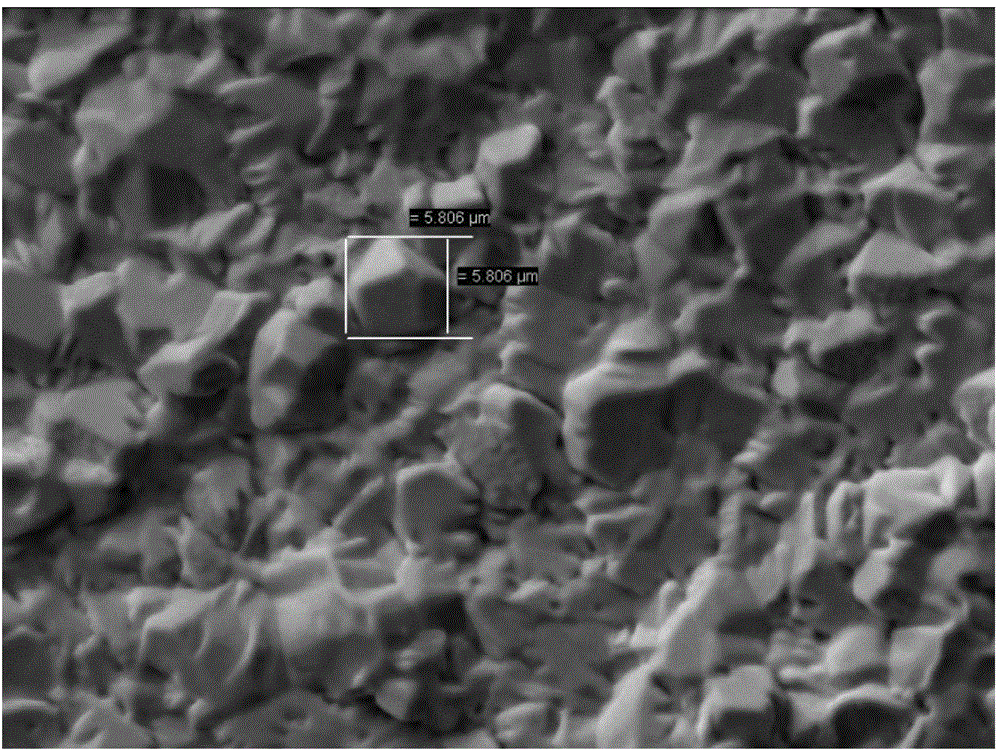

[0058] Test Resul...

Embodiment example 3

[0062] A multifunctional semi-white bright tin plating additive formulated from the following raw materials:

[0063] 12 parts of isopropanol, 33.5 parts of dipropylene glycol methyl ether, 0.5 parts of formaldehyde, 5 parts of bisphenol A polyoxyethylene (15) ether, 8 parts of nonylphenol polyoxyethylene (10) ether, 2.5 parts of catechol, 0.5 parts of gelatin, 0.3 parts of pyridine-modified quaternary ammonium salts, 0.1 parts of diaminodiphenylmethane, 0.1 parts of ethylenediaminetetraacetic acid, 0.1 parts of sodium hypophosphite, 0.8 parts of methanesulfonic acid, 0.05 parts of polyacrylamide, deionized 36.55 parts of water.

[0064] test:

[0065] Slowly add the pre-prepared additive to the base liquid of stannous methanesulfonate under stirring condition, the addition amount is 2-4mL / L, after stirring evenly, use the Hull cell test.

[0066] Hull cell conditions: θ is 45°, current 1A, temperature 38-45°C, time 45-85 seconds

[0067] Test Results:

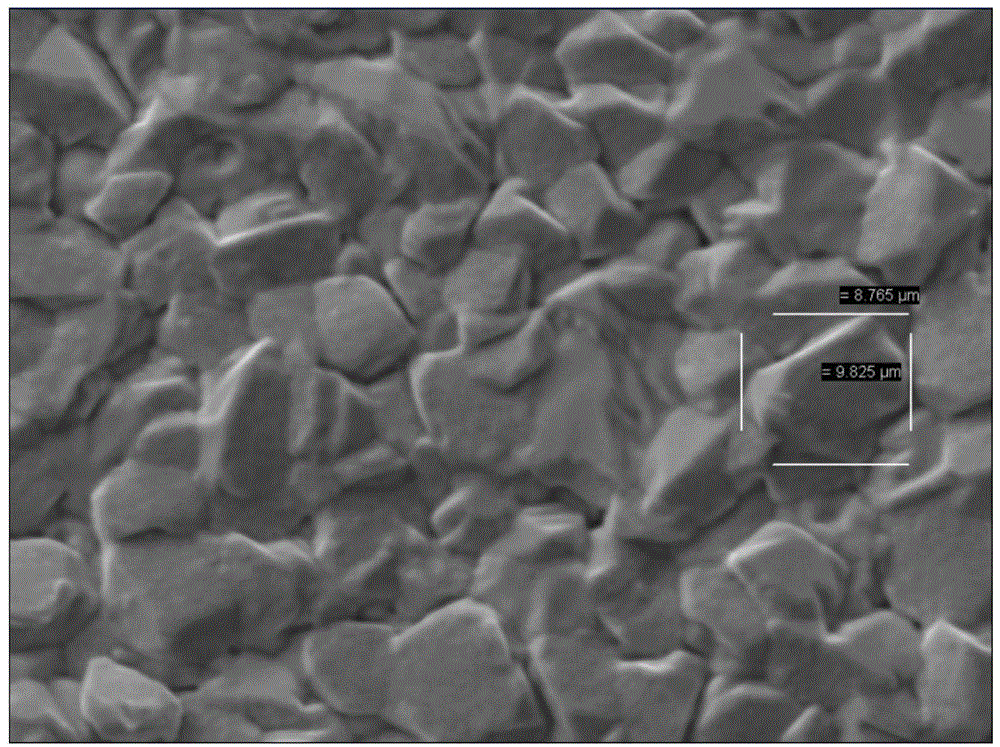

[0068] The results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com