High corrosion resistance zinc-nickel alloy electroplating additive with weak acidity to neutrality and electroplating liquid

An electroplating additive, zinc-nickel alloy technology, applied in the field of metal surface treatment, can solve the problems affecting the service life of the equipment, complicated operation process, unstable pH of the plating solution, etc., to increase the current density range, high current efficiency, and corrosion resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

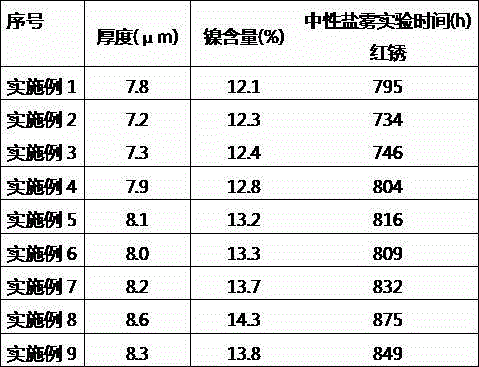

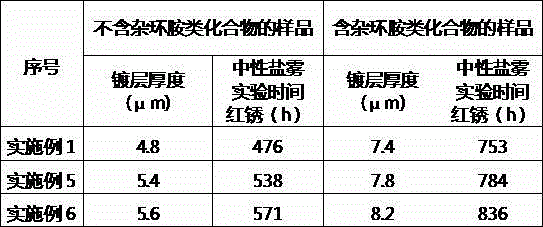

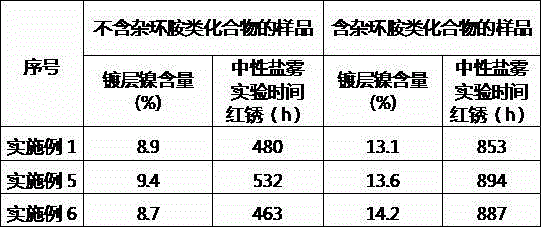

Examples

Embodiment 1

[0033] The composition of the basic solution is: potassium chloride 150g / L, potassium acetate 35g / L, zinc chloride 54g / L, and nickel chloride 57g / L. Add complexing agent: 62ml / L, brightening agent: 23ml / L, and positioning agent: 3ml / L to the above weak acid to neutral base solution, and stir evenly to obtain zinc-nickel alloy electroplating solution.

[0034] Among them, the 62ml / L complexing agent composition (mass fraction) is 7% of acetylsalicylic acid, 42% of caprolactam, and water as the balance.

[0035] Among them, the 23ml / L brightener composition (mass fraction) is: 20% potassium hydroxymethanesulfonate, 5% diaminocarbazide polymer, and water as the balance.

[0036] Among them, the composition (mass fraction) of 3ml / L positioning agent is maleic anhydride 6%, dispersant NNO (sodium methylene naphthalene sulfonate) 3.5%, niacin 16%, and water as the balance.

Embodiment 2

[0038] The composition of the base solution is: potassium chloride 176g / L, potassium acetate 38g / L, zinc chloride 50g / L, and nickel chloride 67.5g / L. Add complexing agent: 60ml / L, brightening agent: 24ml / L, and positioning agent: 3.5ml / L to the above weak acid to neutral base solution, and stir well to obtain zinc-nickel alloy electroplating solution.

[0039] Among them, the composition (mass fraction) of the 60ml / L complexing agent is 7.5% of acetylsalicylic acid, 35% of β-propiolactam, and water as the balance.

[0040] Among them, the composition (mass fraction) of 24ml / L brightener is 29% sodium propargyl sulfonate, 4.2% diaminourea polymer, and water as the balance.

[0041] Among them, the 3.5ml / L positioner composition (mass fraction) is maleic anhydride 5%, dispersant NNO (sodium methylene naphthalene sulfonate) 5.4%, niacin amine 10%, and water as the balance.

Embodiment 3

[0043] The composition of the base solution is: potassium chloride 168g / L, potassium acetate 43g / L, zinc chloride 58g / L, and nickel chloride 55g / L. Add complexing agent: 82ml / L, brightening agent: 25ml / L, and positioning agent: 4ml / L to the above weak acid to neutral base solution, and stir evenly to obtain zinc-nickel alloy electroplating solution.

[0044] Among them, the composition (mass fraction) of the 82ml / L complexing agent is 5% of acetylsalicylic acid, 30% of imidazole, and water as the balance.

[0045] Among them, the 25ml / L brightener composition (mass fraction) is: sodium allyl sulfonate 18%, diaminocarbazide polymer 2.6%, and water as the balance.

[0046] Among them, the composition of 4ml / L positioning agent (mass fraction) is 8% maleic anhydride, dispersant NNO (sodium methylene naphthalene sulfonate) 4%, 2-chloronicotinic acid 13%, and water as the balance .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com