Electronic cigarette control method and electronic cigarette

A control method and technology of electronic cigarettes, which are applied in the fields of tobacco, smokers’ supplies, applications, etc., can solve the problems of black tobacco, light smoke, uneven heat distribution, etc., and achieve the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

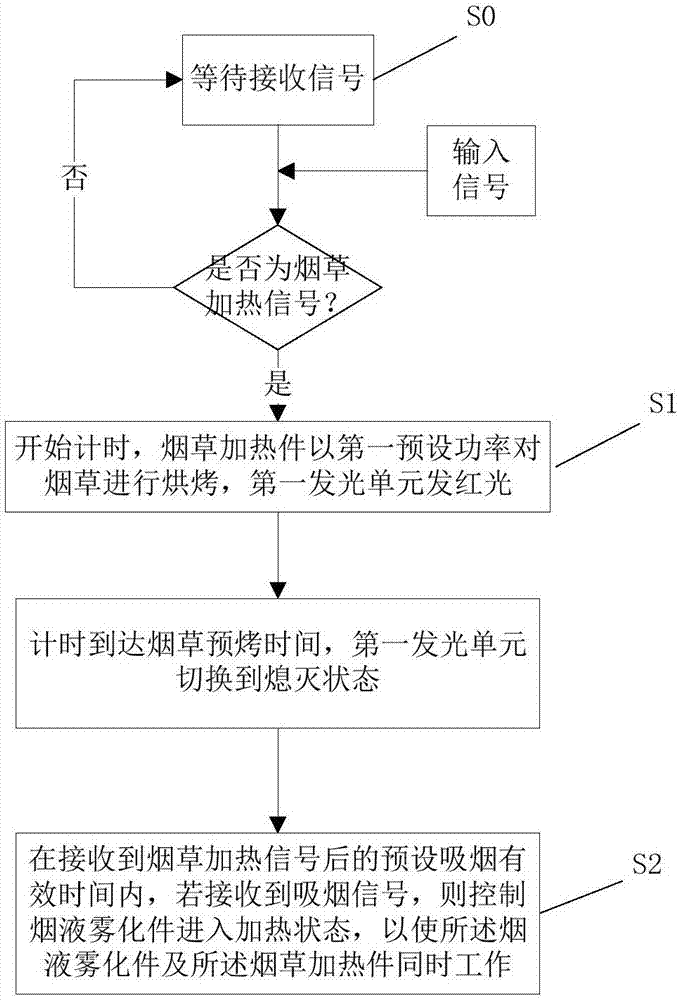

[0037] refer to figure 1 , this embodiment discloses an electronic cigarette control method, the method includes:

[0038] S1. If the tobacco heating signal is received, start timing, and control the tobacco heating element to enter the heating state, and dry the tobacco with the first preset power;

[0039] S2. During the preset effective smoking time after receiving the tobacco heating signal, if the smoking signal is received, control the smoke liquid atomizing part to enter the heating state, so that the smoke liquid atomizing part and the tobacco heating part are simultaneously When working, the smoke produced by the atomized smoke oil of the smoke liquid atomizer flows into the tobacco area where the heating element is toasted and continues to steam the tobacco, so as to mix with the smoke produced by the tobacco heating piece to be discharged for use users smoke;

[0040] Wherein, the tobacco heating signal is a signal generated by pressing a flue-cured tobacco button...

Embodiment 2

[0063] refer to Figure 4 The difference between the second embodiment and the first embodiment is that the use prompt information in the second embodiment is that the second light-emitting unit emits green light, and the light of the first light-emitting unit is used to remind the user that it cannot be used.

[0064] Specifically: in step S1, when the tobacco heating signal is received, the tobacco heating element is controlled to enter the heating state and at the same time the first light-emitting unit is controlled to emit red light. When the tobacco pre-curing time is specified, the first light-emitting unit is controlled to switch to the extinguished state, and the second light-emitting unit is controlled to emit green light at the same time.

[0065] Correspondingly, in step S2, when controlling the tobacco heating element to stop working and ending smoking, it is also necessary to control the second light-emitting unit to switch to the extinguished state.

[0066] re...

Embodiment 3

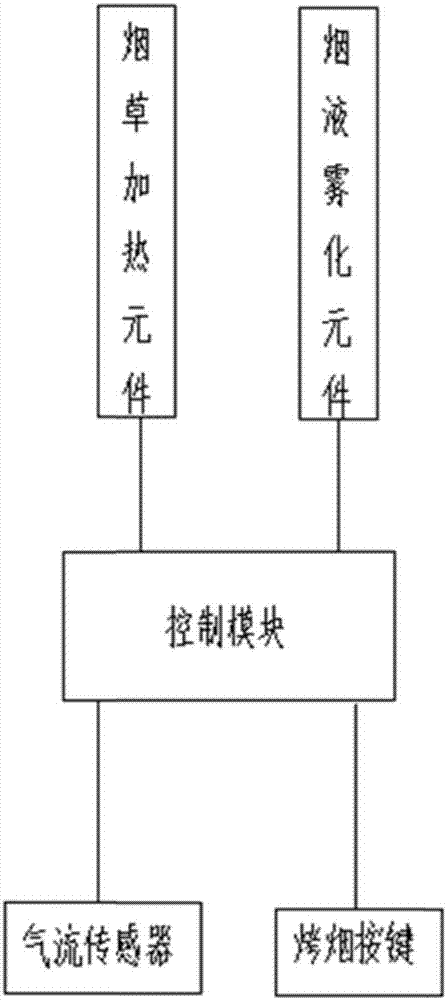

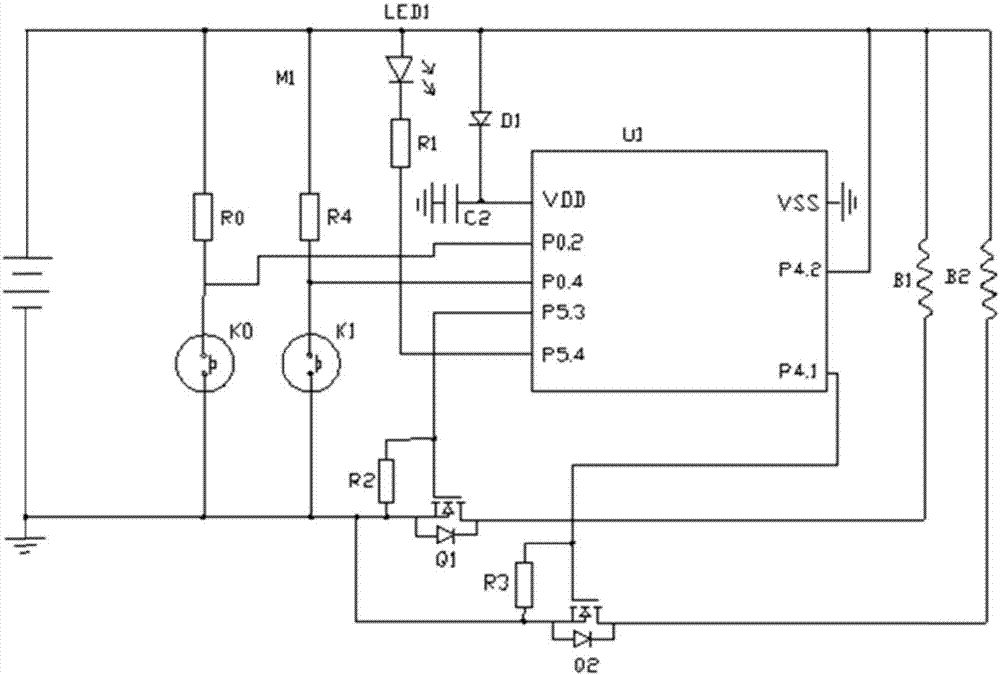

[0069] Based on the same inventive concept, this embodiment discloses an electronic cigarette. The electronic cigarette includes a battery rod and an atomizer for performing the above method, the atomizer includes an atomization channel communicated with the smoke exhaust port, and the atomization channel is set in an area on the smoke circulation path away from the smoke exhaust port With the smoke liquid atomizer, the atomization channel is provided with tobacco and a tobacco heating element in the area between the smoke exhaust port and the smoke liquid atomizer on the smoke flow path, so that the smoke liquid atomizer When the smoke generated by the atomized e-liquid flows into the area of the tobacco to be cured by the heating element, the tobacco continues to be vaporized, so as to mix with the smoke generated by the tobacco heating element and then discharged from the smoke outlet for the user to smoke.

[0070] refer to Figure 6, in a specific embodiment, the atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com