Aluminum slag recovery equipment and process

A technology for recycling equipment and aluminum slag, which is applied in the field of aluminum slag recycling equipment and aluminum slag recycling technology, can solve the problems of immature technology, secondary pollution, low recovery rate, etc., and achieve saving of aluminum resources, reduction of harmful substances, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

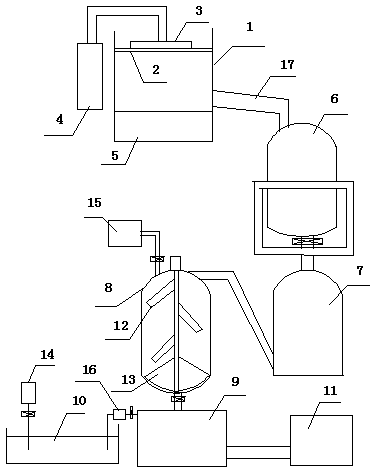

[0022] Such as figure 1 As shown, a kind of aluminum slag recovery equipment includes primary recovery equipment, secondary recovery equipment and slag ash processing equipment, the primary recovery equipment includes a slag pressing box 1, and the upper part of the slag pressing box 1 is provided with a movable up and down Pressing plate 2, above the pressing plate is provided with a pressure head 3 that can move up and down, the pressing head 3 is connected with the hydraulic press 4, and the pressing head 3 can apply pressure to the pressing plate 2 downward under the action of the hydraulic press 4. The lower bottom surface of the slag box 1 is provided with a through hole for liquid aluminum to pass through, and a liquid aluminum collection box 5 is provided below the slag box 1; the secondary recovery equipment includes a heating furnace 6, and the inside of the slag box 1 is The aluminum slag is transported into the feed inlet of the heating furnace 6 through the convey...

Embodiment 2

[0027] A kind of aluminum slag recovery process, utilizes described aluminum slag recovery equipment, comprises the following steps:

[0028] (1) One-time recovery: put the aluminum slag taken out from the furnace into the slag pressing box 1, and then start the hydraulic press 4, so that the pressure head 3 presses down on the pressing plate 2 under the action of the hydraulic press 4 to squeeze the aluminum slag. The aluminum liquid in the aluminum slag flows into the aluminum liquid collection box 5 through the through hole on the lower bottom surface, and then flows back into the melting furnace for further utilization;

[0029] (2) Secondary recovery: take out the remaining aluminum slag from step 1 from the slag pressing box 1, and then transport it into the heating furnace 6 through the conveying device to heat it to 700°C, keep it warm for 60 minutes, and then transfer it to the centrifuge for separation , the separated molten aluminum is returned to the furnace for fu...

Embodiment 3

[0033] A kind of aluminum slag recovery process, utilizes described aluminum slag recovery equipment, comprises the following steps:

[0034] (1) One-time recovery: put the aluminum slag taken out from the furnace into the slag pressing box 1, and then start the hydraulic press 4, so that the pressure head 3 presses down on the pressing plate 2 under the action of the hydraulic press 4 to squeeze the aluminum slag. The aluminum liquid in the aluminum slag flows into the aluminum liquid collection box 5 through the through hole on the lower bottom surface, and then flows back into the melting furnace for further utilization;

[0035] (2) Secondary recovery: take out the remaining aluminum slag in step 1 from the slag pressing box 1, and then transport it into the heating furnace 6 through the conveying device for heating to 850°C, keep it warm for 30 minutes, and then transfer it to the centrifuge for separation , the separated molten aluminum is returned to the furnace for fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com