Humic fertilizer and preparation method thereof

A humic acid and fertilizer technology, applied in the field of organic fertilizer preparation, organic fertilizer and humic acid fertilizer, can solve problems such as restricting the obtaining efficiency of humic acid, no continuous preparation method, etc. The preparation method has a short process and the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Raw material crushing

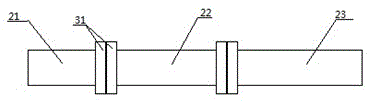

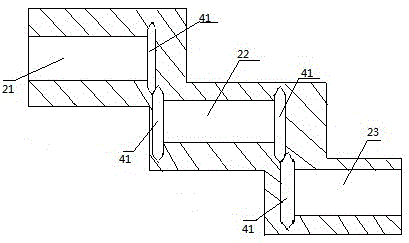

[0029] Put the mixture of rice straw and apple core and coal gangue into the three-stage screw extruder (hereinafter referred to as the screw extruder) according to the mass ratio of 8:1, and crush it by the first stage screw 21 , get base material;

[0030] 2) Mild enzymatic hydrolysis

[0031] The base material enters the second section screw rod 22 from the first section screw rod 21, and the screw extruder is heated by water to make the internal temperature corresponding to the second section screw rod 22, and water and acetic acid are added thereto to adjust the base material The pH value is 6.0, the water content is 40%, and then add laccase, exo-β-glucanase, endo-β-glucanase and β-glucoside with a total mass of about 10% of the raw material mass Enzymes, adjust the rotating speed of the second stage screw 22, so that the base material runs from the rear of the second stage screw 22 to the front of the second stage screw 22, and the ba...

Embodiment 2

[0038] 1) Raw material crushing

[0039] Putting the mixed mixture of rice straw and fallen leaves and coal gangue into the screw extruder according to the mass ratio of 9:1, and crushing it by the first screw 21 to obtain the base material;

[0040] 2) Mild enzymatic hydrolysis

[0041]The base material enters the second section screw rod 22 from the first section screw rod 21, and the screw extruder is heated by water to make the internal temperature corresponding to the second section screw rod 22, and water and acetic acid are added thereto to adjust the base material The pH value is 6.0, the water content is 30%, and then add laccase, exo-β-glucanase, endo-β-glucanase and β-glucoside with a total mass of about 10% of the raw material mass Enzyme, wherein laccase quality accounts for 60% of these several kinds of enzyme total mass, regulates the rotating speed of second section screw 22, makes base material run to the front of second section screw 22 from second section s...

Embodiment 3

[0047] 1) Raw material crushing

[0048] Put the mixed mixture of fruit stones and bamboo branches and coal gangue into the screw extruder according to the mass ratio of 10:1, and crush it by the first screw 21 to obtain the base material;

[0049] 2) Mild enzymatic hydrolysis

[0050] The base material enters the second section screw rod 22 from the first section screw rod 21, and the screw extruder is heated by water to make the internal temperature corresponding to the second section screw rod 22, and water and acetic acid are added thereto to adjust the base material The pH value is 6.0, the water content is 50%, and then add laccase, exo-β-glucanase, endo-β-glucanase and β-glucoside with a total mass of about 10% of the raw material mass Enzyme, wherein laccase quality accounts for 20% of these several kinds of enzyme total mass, regulates the rotating speed of second stage screw 22, makes base material move to second section screw rod 22 front from the second section sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com