Sludge dryer with increased retention time

A technology of sludge drying and residence time, applied in the fields of sludge drying, sludge treatment, sludge treatment, etc., can solve the problems of heat loss and difficulty in recovering heat, so as to reduce the treatment cost and time, and improve the reuse value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

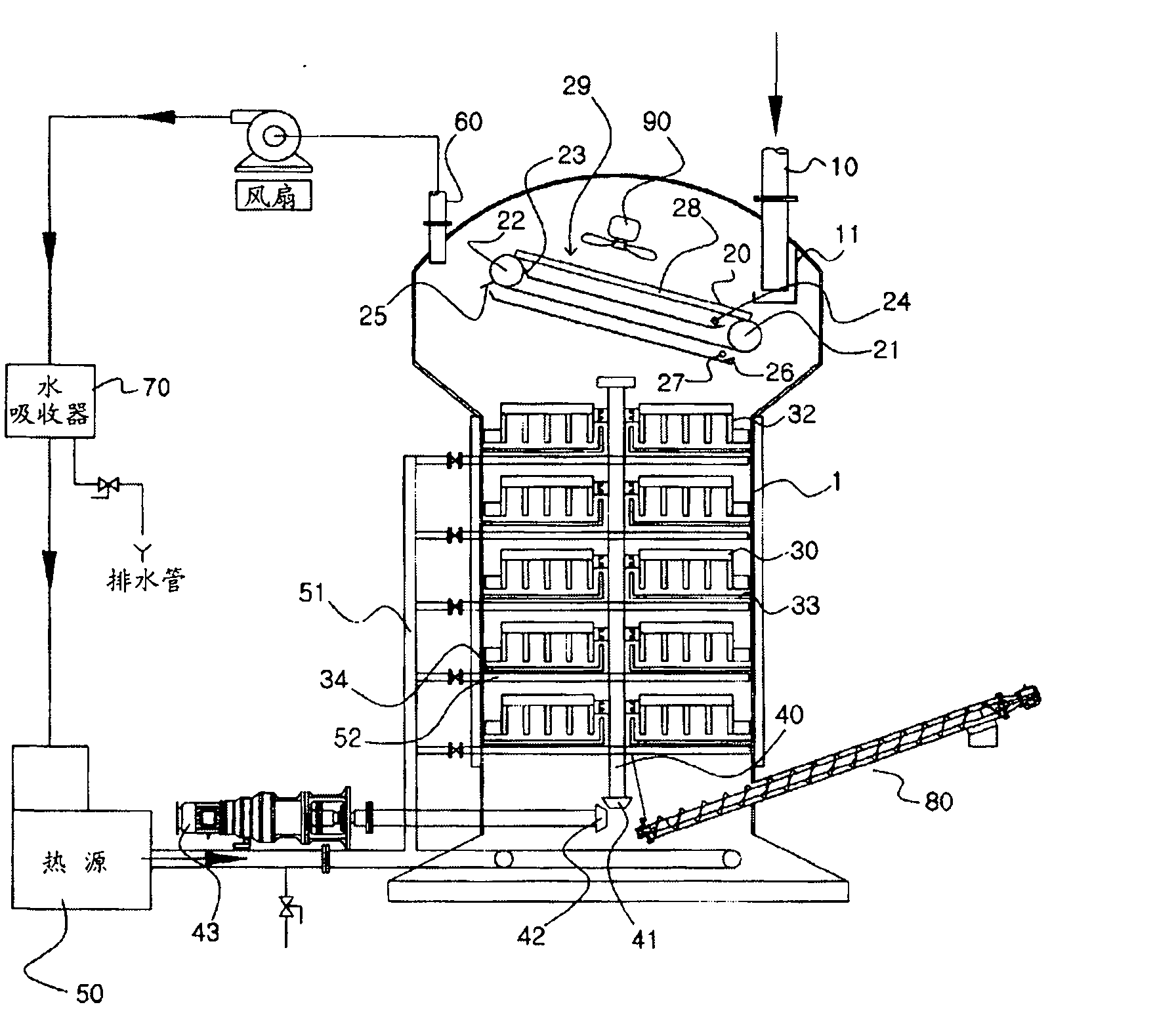

[0037] The configuration and structure of the present invention will be described in detail below with reference to the drawings.

[0038] figure 1 It shows the alternating type sludge drying apparatus which increased the residence time of this invention. A cylindrical main body 1 is formed on this device, and a space is formed inside it so that sludge can be thrown in and dried, and through an inlet 10 formed on the upper part of the main body for introducing sludge from the outside, the sludge is It is supplied into the main body 1.

[0039] The sludge supplied through the above-mentioned inlet 10 is supplied to a wire box (Wire box) 11 arranged below the inlet, and the sludge supplied to the above-mentioned wire box overflows from the wire box, and the sludge overflowing the wire box is supplied to the wire box again. Water eliminator 29.

[0040] However, the sludge may be directly supplied from the inlet 10 to the water eliminator 29 without using the wire box. Above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com