Harmless treatment system for oil field sludge

A technology for harmless treatment of oilfield sludge, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, special treatment targets, etc. Pollution, difficulty in centralized treatment and other problems, to achieve the effect of controlling the emission of dioxins and heavy metals, long burning time, and complete burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

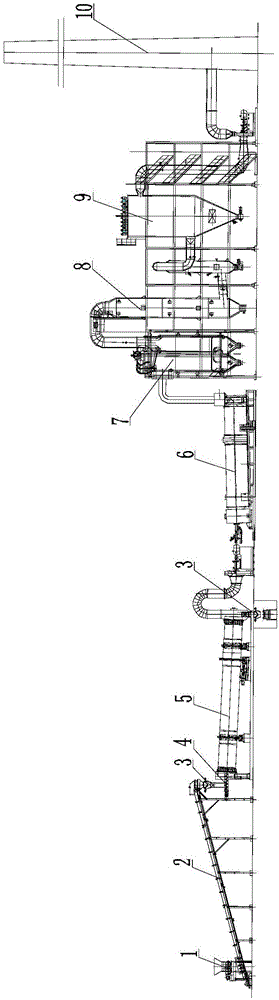

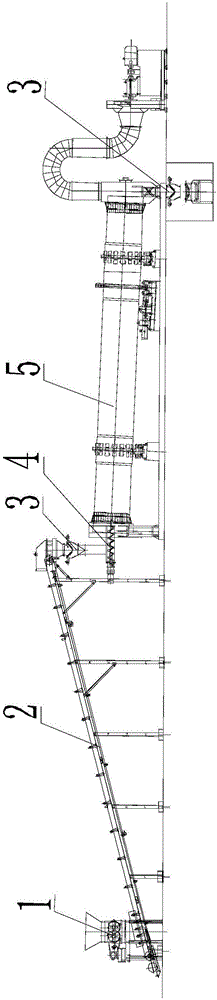

[0040] The specific embodiment of the present invention is shown in the accompanying drawings. The oilfield sludge harmless treatment system includes: a feeding device, a rotary dryer 5, a catalytic pyrolysis furnace 6, a waste heat boiler 7, a quench tower 8, an absorption tower 9 and a chimney 10;

[0041] The feeding device is located at the inlet end of the rotary dryer 5, and feeds the sludge into the rotary dryer 5;

[0042] The outlet end of the rotary dryer 5 is connected to the inlet end of the catalytic pyrolysis furnace 6; the dried oil sludge and waste gas are sent into the catalytic pyrolysis furnace 6;

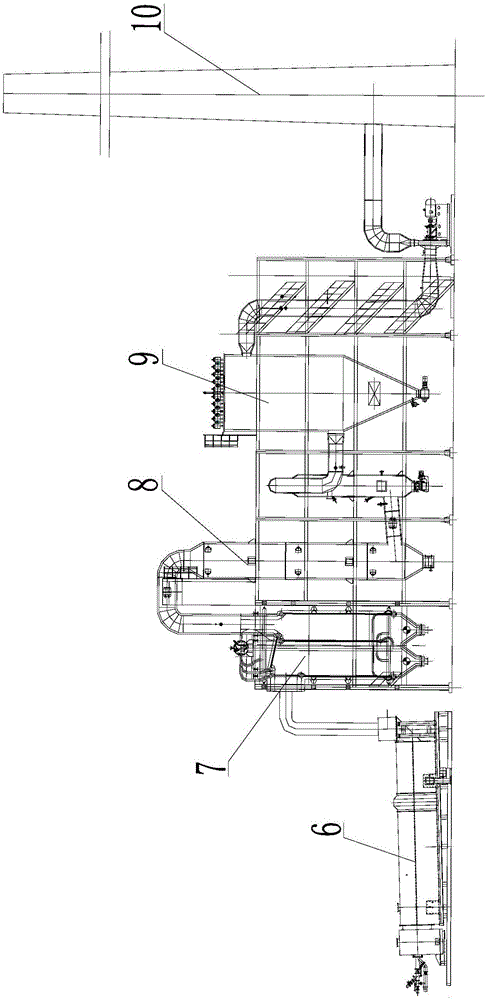

[0043]The outlet end of the catalytic pyrolysis furnace is connected to the inlet end of the waste heat boiler 7, and the flue gas is sent to the waste heat boiler for heat exchange;

[0044] Two outlets of the waste heat boiler 7 are designed; one outlet is connected to the inlet of the absorption tower 9 to collect dust particles in the flue gas; the other out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com