Equipment using industrial waste to prepare calcium silicate hydrate and magnetic hydrotalcite

A technology of hydrated calcium silicate and magnetic hydrotalcite, applied in hydrotalcite, lighting and heating equipment, solid waste removal, etc., can solve the problems of low added value, focus on effective treatment of primary waste, lack of effective treatment and utilization, etc. , to achieve the effect of large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

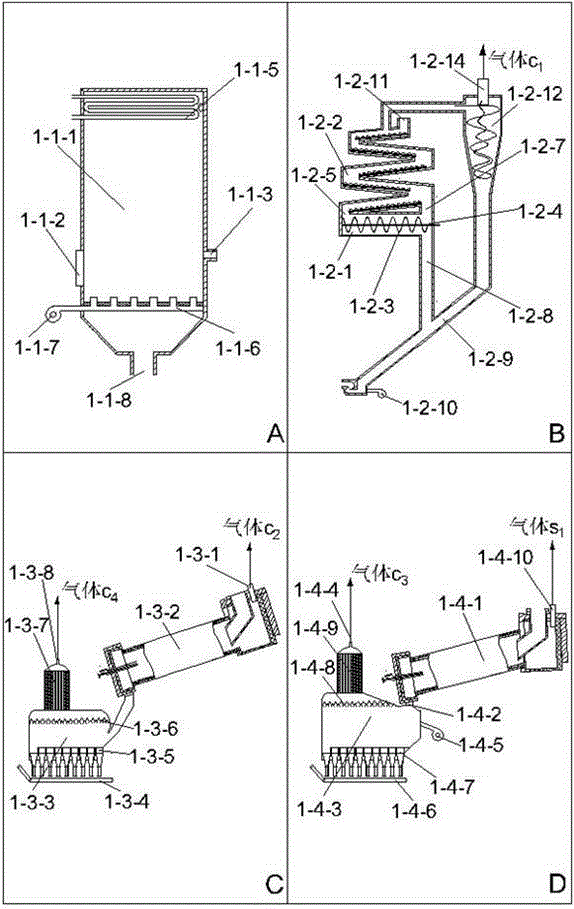

[0070] A device for preparing calcium silicate hydrate and magnetic hydrotalcite from industrial waste, The first part is white mud, high sulfur coal Burn activation system: In the fluidized combustion device (1-1), the middle and lower part of the side wall of the fluidized combustion chamber (1-1-1) is respectively equipped with a high-sulfur coal white mud mixture feed port (1-1-2) and a fluidized combustion chamber lime mud The feed inlet (1-1-3), the upper part of the side wall is equipped with a flue gas discharge port (1-1-4) and a superheater (1-1-5), and the lower part of the fluidized combustion chamber (1-1-1) The air distribution pipe (1-1-6) is connected to the first fan (1-1-7), and the bottom of the fluidized combustion chamber (1-1-1) is provided with a first outlet (1-1-8) ;The lime mud preheating device (1-2) is equipped with the lime mud gas-solid mixer (1-2-1) and the lime mud conveyor (1-2-2); the lime mud conveyor (1-2-2) The upper part is equipped wi...

Embodiment 2

[0076] This embodiment is basically the same as Embodiment 1, and is characterized in that the first part is the first opening (1-2-5) and the second opening in the lime mud preheating device (1-2) of the high-sulfur coal combustion activation system. (1-2-6) and the third opening (1-2-13); the distance between adjacent openings is greater than the distance between the two closest edge co-location points of the screw propeller (1-2-3); the The co-location point of the edge is the contact point between the screw propeller (1-2-3) and the horizontal plane when the screw propeller (1-2-3) is placed on the horizontal plane.

[0077] In this embodiment, the distance between 3 openings is set to prevent the lime mud from entering the relevant gas path when it enters the lime mud gas-solid mixer (1-2-1); at the same time, it can prevent the gas from entering other pipelines.

Embodiment 3

[0079] This embodiment is basically the same as Embodiment 1, and it is characterized in that the angle between the direction of the exhaust port of the third fan (1-4-5) in the high-temperature calcination device (1-4) and the discharge pipe (1-4-2) 30-60 degrees; preferably 45 degrees.

[0080] If the angle is too small, it will accelerate the cooling of the material in the discharge pipe (1-4-2), making it difficult to discharge; if the angle is too large, the horizontal head of the material will be too large, and the cooling will not be sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com