Method for preparing nanometer compound powder and product

A technology of nano-compounds and powders, which is applied in the direction of titanium compounds, phosphorus compounds, chemical instruments and methods, etc., which can solve the problems of difficult control of the process of nano-powders, uneven size distribution, large grain size of products, etc., and achieve the purpose of inhibiting coalescence and growth, elimination of local concentration and temperature unevenness, stable combustion temperature and combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

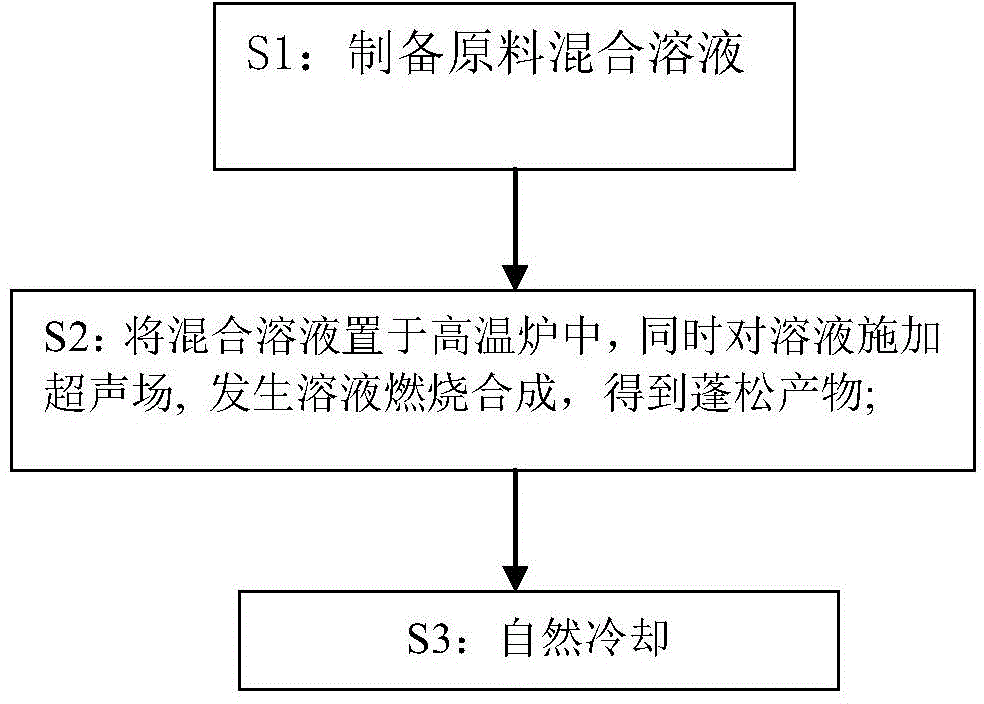

Method used

Image

Examples

Embodiment 1

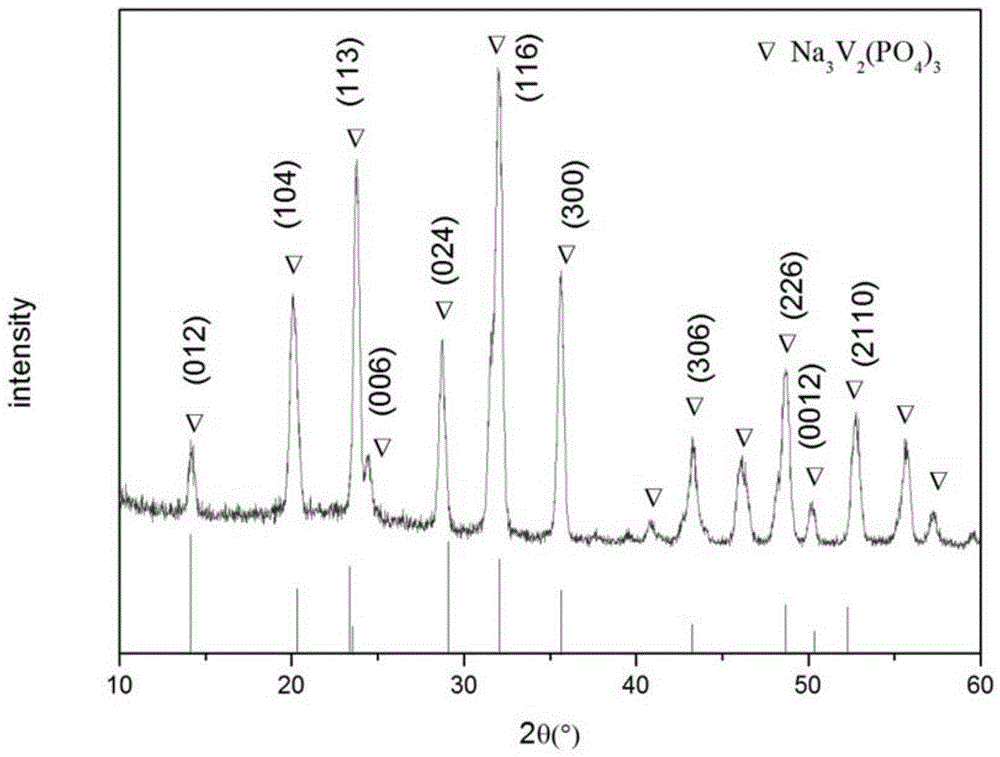

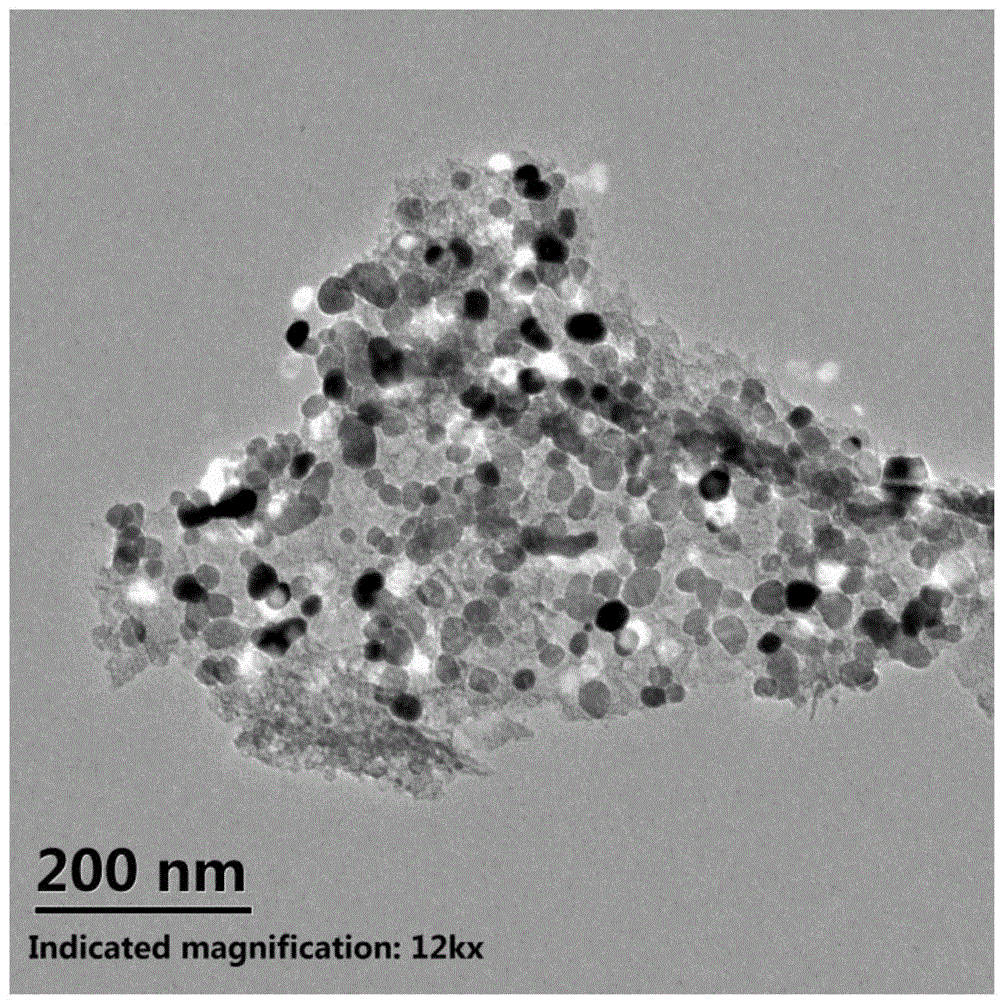

[0041] This example is used to synthesize Na 3 V 2 (PO 4 ) 3 Nano powder:

[0042] S1: Prepare the mixed solution of raw materials, specifically, first mix 3.13g of C 6 h 8 o 7 , 2.34g of NH 4 VO 3 , 2.55g of NaNO 3 and 3.45 g of NH 4 h 2 PO 4 respectively dissolved in appropriate amount of deionized water, C 6 h 8 o 7 、NaNO 3 and NH 4 h 2 PO 4are completely soluble in deionized water corresponding to three clear and transparent solutions, while NH 4 VO 3 Slightly soluble in deionized water to obtain a white suspension. Then white NH 4 VO 3 The suspension was added dropwise to C 6 h 8 o 7 solution, followed by NaNO 3 solution and NH 4 h 2 PO 4 The solution was added to the above solution to obtain 200 ml of a mixed solution. The resulting 200ml mixed solution was stirred in a 60°C water bath for 2h to obtain a dark blue clear raw material mixed solution.

[0043] S2: placing the mixed raw material solution at a temperature of 200° C. to 700° C., ...

Embodiment 2

[0049] This embodiment is used to synthesize Li 2 TiO 3 -Li 2 SiO 3 Composite nanopowder.

[0050] S1: prepare the mixed solution of raw materials, specifically, at first: respectively mix 4.38g of C 6 h 8 o 7 and 6.90 g of LiNO 3 were dissolved in appropriate amount of deionized water to obtain clear solutions respectively, and then LiNO 3 solution was added to C 6 h 8 o 7 In the solution, the above solution was stirred and mixed, and then 5.21g of tetraethyl orthosilicate was dropped into the solution containing LiNO 3 and C 6 h 8 o 7 The mixed solution was stirred in a water bath at 60° C. for 2 h to obtain a lithium orthosilicate precursor solution. In addition, 8.50 g of tetrabutyl titanate was added to an appropriate amount of water for hydrolysis to form a white precipitate. The precipitate was centrifuged and washed, and then 30 mL of distilled water and about 20 mL of concentrated nitric acid were added to the precipitate in order to dissolve the precipi...

Embodiment 3

[0056] This embodiment is used to synthesize Li 2 TiO 3 Nano powder.

[0057] S1: Prepare a mixed solution of raw materials. Specifically, first, add 6.81 g of tetrabutyl titanate to an appropriate amount of water for hydrolysis to form a white precipitate, centrifuge and wash the precipitate, and then add 30 mL of distilled water and 15 mL of Concentrated nitric acid to dissolve the precipitate to obtain a transparent titanium salt solution. 2.76g of LiNO 3 and 3.54g of C 6 h 8 o 7 Dissolve in appropriate amount of deionized water respectively to obtain a clear solution. Titanium salt solution and LiNO 3 solution was added to C 6 h 8 o 7 solution, 50 mL of a clear mixed solution of raw materials was obtained.

[0058] S2: Move the mixed solution into a crucible and place it in a muffle furnace at 500°C. At the same time, apply ultrasonic treatment to the mixed solution. The ultrasonic frequency is 20kHZ, the ultrasonic power is 2kW, the ratio of ultrasonic pulse ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com