Device for condensation liquefaction recovery of organic exhaust gas

A recovery device and organic waste gas technology, applied in the direction of steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of secondary water pollution, lower reuse value, high replacement cost, etc., to reduce the cost of waste gas recovery and reuse The effect of high value and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

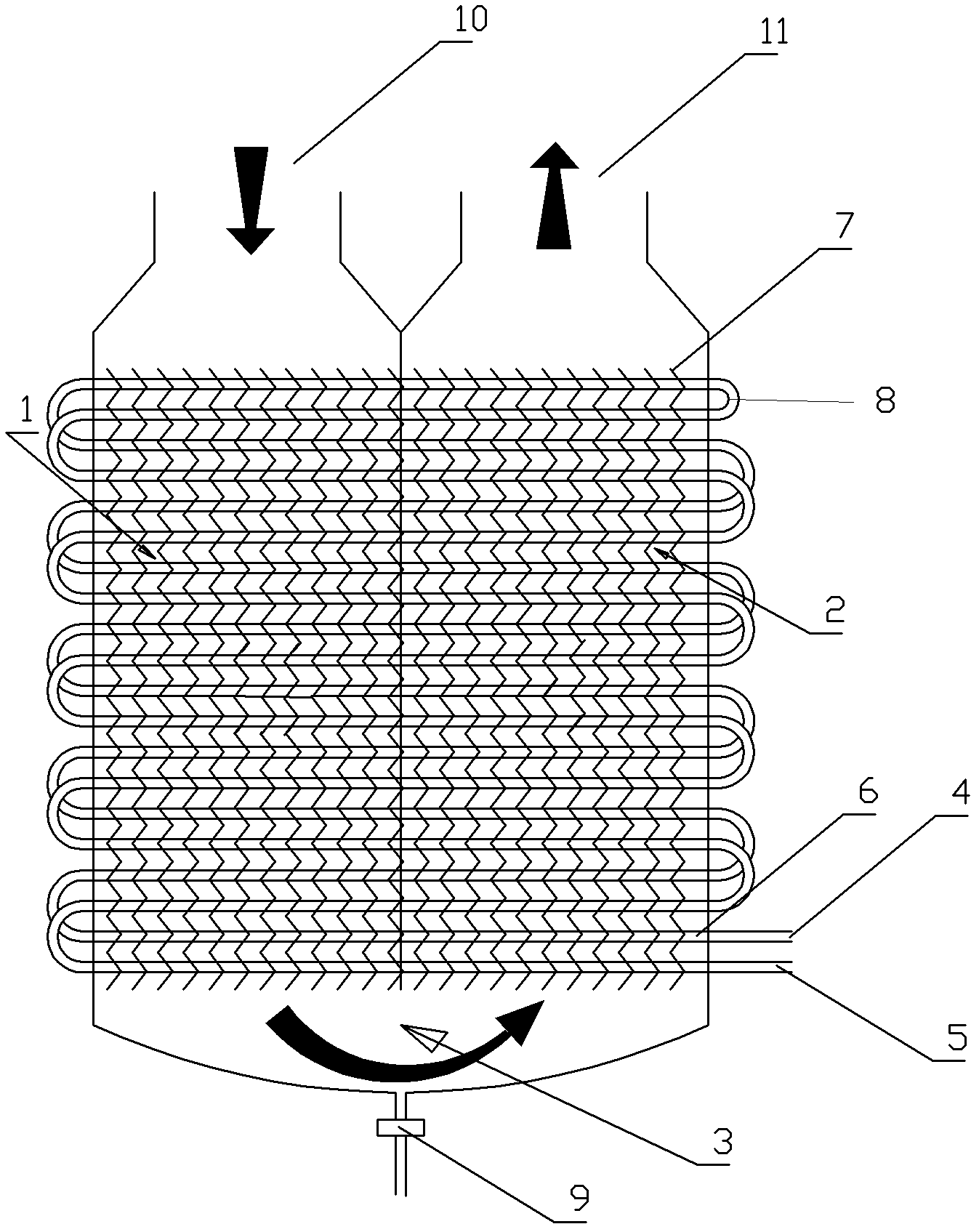

[0021] Embodiment 1: as figure 1 As shown, the organic waste gas condensate liquefaction recovery device includes an inlet heat exchange chamber 1, an outlet heat exchange chamber 2, and a liquid inlet pipe 6, and heat sinks 7 are respectively arranged in the inlet heat exchange chamber 1 and the outlet heat exchange chamber 2, and the inlet The liquid pipe 6 detours upwards from low to high and then turns back close to the original path. The horizontal pipe sections of the liquid inlet pipe 6 pass through the heat sinks 7 respectively; The top of the chamber 2 is provided with an outlet 11; the bottom of the air inlet heat exchange chamber 1 communicates with the bottom of the air outlet heat exchange chamber 2 through a sealed connection chamber 3, and the sealed connection chamber 3 is provided with a discharge control outlet. Its sealed connection cavity is funnel-shaped. The discharge control outlet is connected to the discharge valve 9. The sealed connection chamber ca...

Embodiment 2

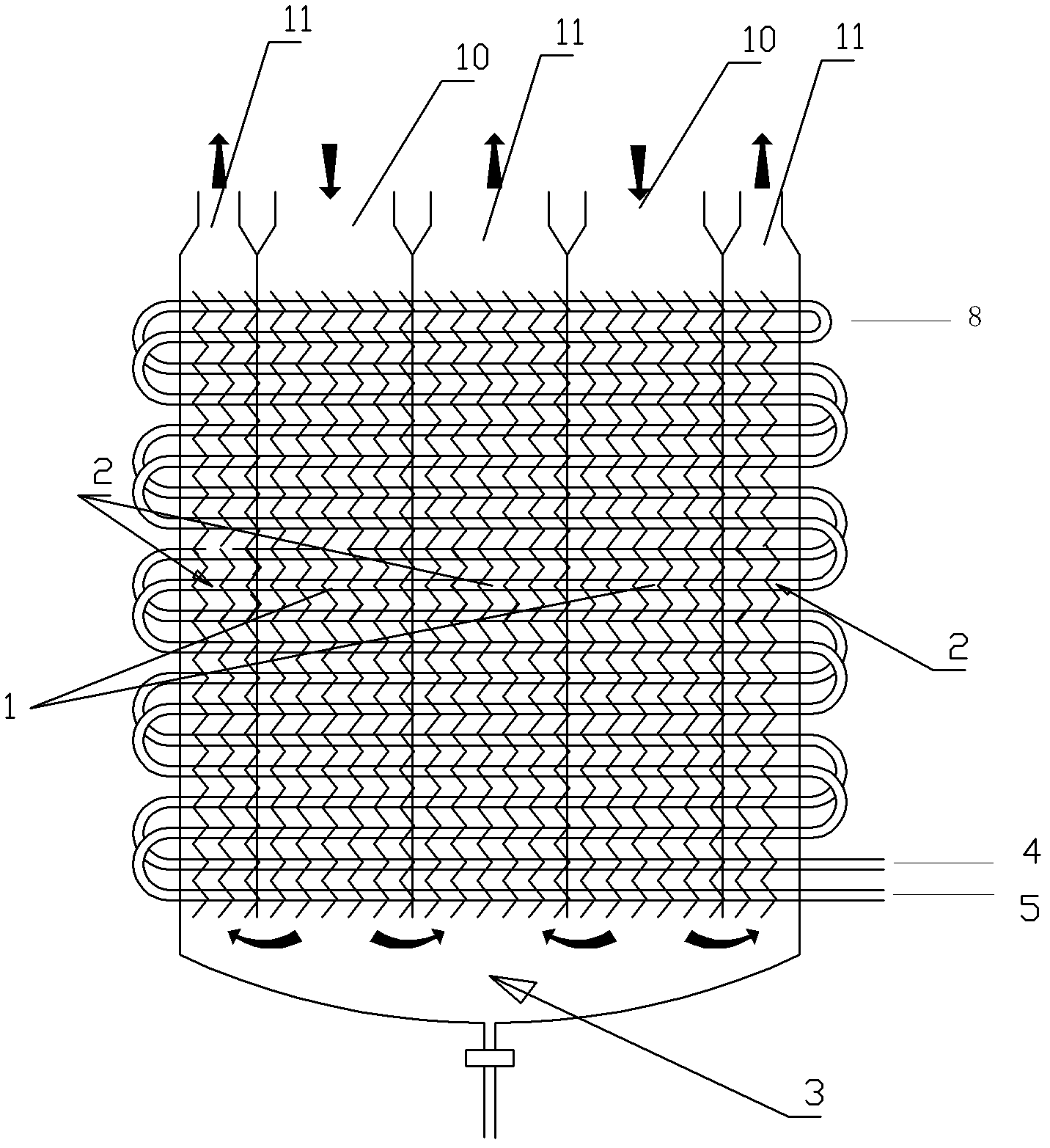

[0051] Embodiment 2: as figure 2 As shown, the organic waste gas condensate liquefaction recovery device is characterized in that it includes an inlet heat exchange chamber, an outlet heat exchange chamber, and a liquid inlet pipe. The heat exchange chamber and the air outlet heat exchange chamber are arranged in sequence, the intake heat exchange chamber is located between two adjacent air outlet heat exchange chambers, or the outlet heat exchange chamber is located between two adjacent intake heat exchange chambers; The heat exchange chamber and the air outlet heat exchange chamber are respectively equipped with cooling fins. The liquid inlet pipe extends from low to high and then turns back close to the original path. The horizontal pipe sections of the liquid inlet pipe pass through the heat sinks respectively; The top of the chamber is provided with an inlet, and the top of the outlet heat exchange chamber is provided with an outlet; the bottom of the inlet heat exchange...

Embodiment 3

[0054] Embodiment 3: The sealed connection chamber is provided with a liquid storage chamber, and the liquid storage chamber is located at the lowest position of the device. In this way, no matter whether the device is placed horizontally or inclined, as long as the liquid storage cavity is kept at the lowest position of the device, it can have a liquid storage function. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com