Resource recycling method for super capacitor

A supercapacitor and recycling method technology, applied in the field of energy materials, can solve the problems of not considering removal, large metal ion impurities, not considering environmental impact treatment methods, etc., to achieve the effect of environmental friendliness and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

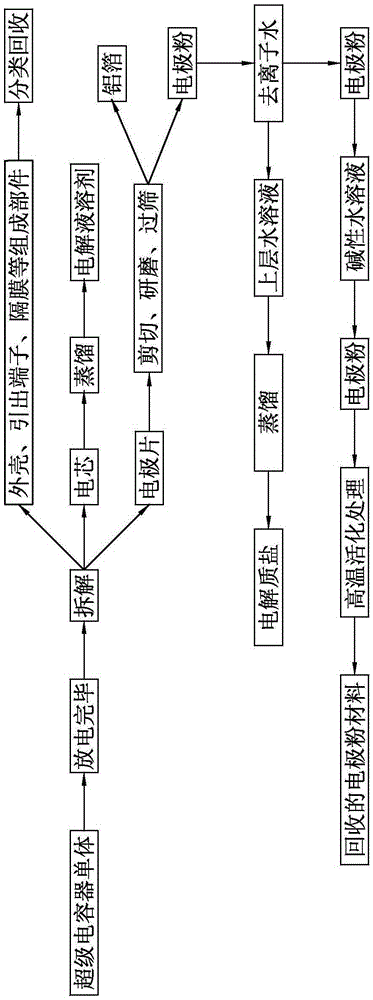

[0028] refer to figure 1 The flow chart of the resource recycling method of supercapacitors. First, the supercapacitors are short-circuit discharged. After the discharge, the supercapacitor monomers are disassembled to obtain the important components of the supercapacitor monomers such as electrode sheets, batteries, casings, lead-out terminals, and diaphragms. Parts, separate recycling.

[0029] Then control the temperature of the cell in it to 100°C to distill off the solvent acetonitrile.

[0030] Cut the electrode sheet into less than 5cm 2 The fragments are ground and the electrode powder falls off from the aluminum foil, and then sieved through a sieve with a pore size of 100 mesh to separate the aluminum foil and electrode powder and recycle the aluminum foil. The electrode powder is washed with deionized water, and the upper layer aqueous solution and the washed electrode powder are separated by filtration with filter paper. The separated upper aqueous solution is d...

Embodiment 2

[0032] refer to figure 1 The flow chart of the resource recycling method of supercapacitors. First, the supercapacitors are short-circuit discharged. After the discharge, the supercapacitor monomers are disassembled to obtain the important components of the supercapacitor monomers such as electrode sheets, batteries, casings, lead-out terminals, and diaphragms. Parts, separate recycling.

[0033] Then control the temperature of the cell in it to 100°C to distill off the solvent acetonitrile.

[0034] Cut the electrode sheet into less than 5cm 2 The fragments are ground and the electrode powder falls off from the aluminum foil, and then sieved through a sieve with a pore size of 100 mesh to separate the aluminum foil and electrode powder and recycle the aluminum foil. The electrode powder was washed with deionized water, and the upper aqueous solution and the washed electrode powder were separated by filtration with filter paper, and repeated once. The separated upper aqueou...

Embodiment 3

[0036] refer to figure 1 The flow chart of the resource recycling method of supercapacitors. First, the supercapacitors are short-circuit discharged. After the discharge, the supercapacitor monomers are disassembled to obtain the important components of the supercapacitor monomers such as electrode sheets, batteries, casings, lead-out terminals, and diaphragms. Parts, separate recycling.

[0037] Then control the temperature of the cell in it to 100°C to distill off the solvent acetonitrile.

[0038] Cut the electrode sheet into less than 5cm 2 The fragments are ground and the electrode powder falls off from the aluminum foil, and then sieved through a sieve with a pore size of 100 mesh to separate the aluminum foil and electrode powder and recycle the aluminum foil. The electrode powder was washed with deionized water, and the upper aqueous solution and the washed electrode powder were separated by filtration with a non-woven fabric, and repeated 3 times. The separated upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com