Intelligent device for green furniture waste material post-treatment

A furniture and green technology, applied in the field of intelligent equipment for post-processing of green furniture waste, can solve the problems affecting the quality of processed products, waste of metal resources, confusion, etc., to improve the processing and drying effect, improve the crushing effect, and easily cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

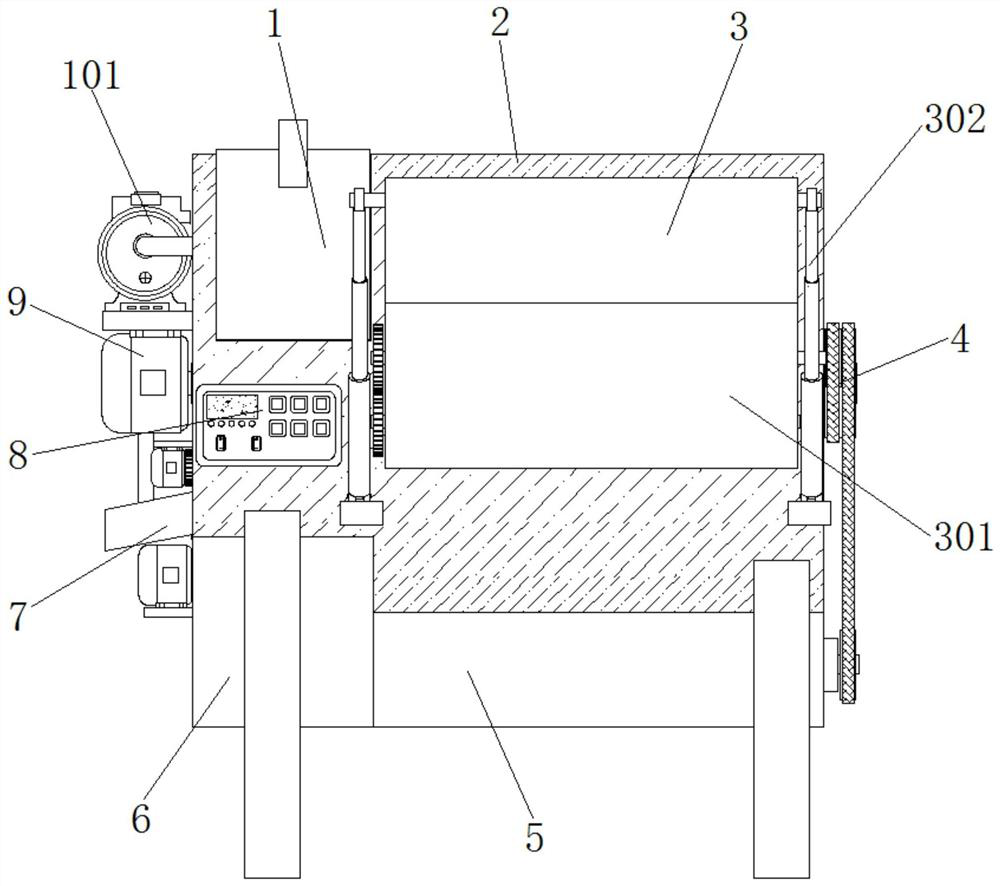

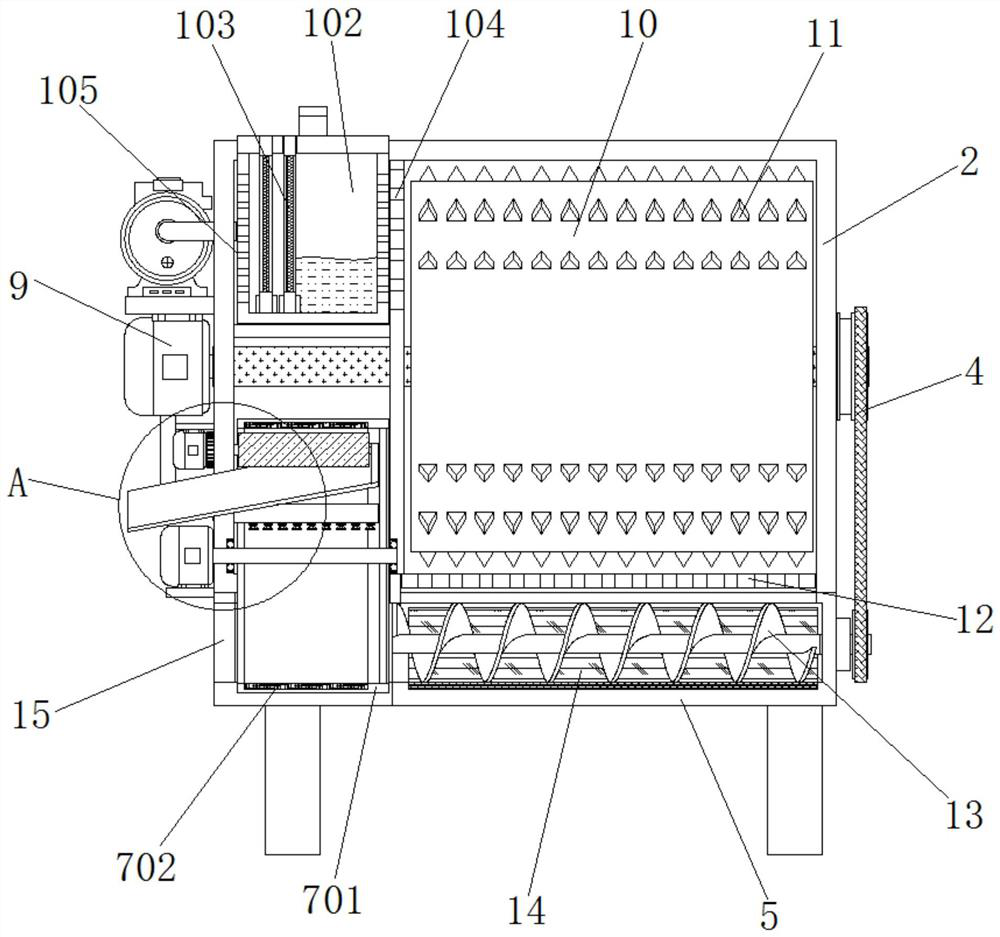

[0043] Example 1, such as Figure 1-4 As shown, after furniture waste materials are put into the interior of the feeding bin 301, the first servo motor 9 is controlled to drive the rotating roller 10 to rotate, and the rotating shaft of the rotating roller 10 can simultaneously drive the screw feeding paddle 13 and crushing through the transmission assembly 4. The roller 306 rotates, and two groups of crushing rollers 306 are used to carry out preliminary crushing treatment on the furniture waste. The movable push plate 303 pushes the remaining furniture waste in the feed bin 301 to two sets of crushing rollers 306, so that all the furniture waste inside the feed bin 301 can be crushed, and then controls the electro-hydraulic rod 302 to extend back to the original position. state, and continue to put furniture waste into the interior of the feed bin 301, so that the equipment can continuously crush the furniture waste.

Embodiment 2

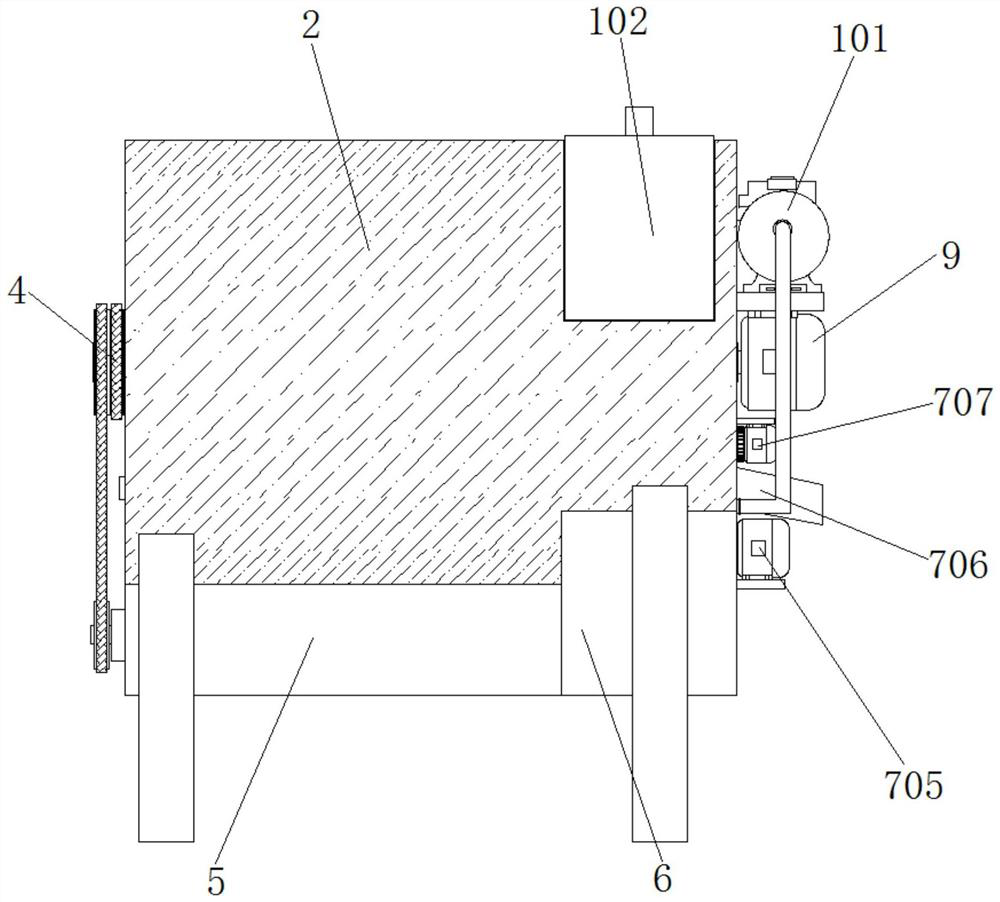

[0044] Example 2, such as figure 1 , 2 , 3, 4, 6, 8, 9 and 10, the wood slag that meets the size of the screen 12 sieve holes in the main body warehouse 2 passes through the screen 12 and falls to the inside of the first cylinder silo 5, if these wood slag are In the wet state, the arc-shaped electric heating plate 14 is controlled by the control panel 8 to heat and dry the wood slag inside the first cylindrical silo 5, and the rotating screw feed paddle 13 gradually removes the wood slag inside the first cylindrical silo 5. The wood residue is transported to the inside of the annular bin 701. At this time, the second servo motor 705 is controlled to drive the annular bin 701 to rotate at a constant speed, so that the wood residue is continuously rolled inside the annular bin 701, and the continuously rolling wood residue will also be easier to dissipate heat, so that all The water vapor in the wood residue is easier to drain away, which improves the processing and drying eff...

Embodiment 3

[0045] Example 3, such as figure 1 , 2 , 3, 4, 5 and 7, in the process of equipment crushing furniture waste, the air pump 101 can be controlled to suck air into the interior of the installation bin 105, forcing the air inside the feed bin 301 and the main body bin 2 to carry The dust is sucked into the inside of the dust removal bin 102 together after passing through the air inlet 104 and the vent hole 106, and the dust is filtered and blocked by two sets of filter screens 103, so that the dust can be easily prevented from affecting the health of the operators around the equipment, and the To prevent the dust from accumulating on the surface of the equipment and affecting the normal operation of the equipment, the filtered air is transported to the inside of the installation pipe 17, and then sprayed by multiple groups of nozzles 18 to the surface of the continuously tumbling wood residue inside the annular warehouse 701, which can further promote wood removal. The heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com