Bulleyaconitine A preparation method

A technology of clathrin and aconitum, applied in the field of preparation of clathrate, can solve the problems of complex method steps, difficult preparation, changes, etc., and achieve the effects of being convenient for recycling, improving working environment, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

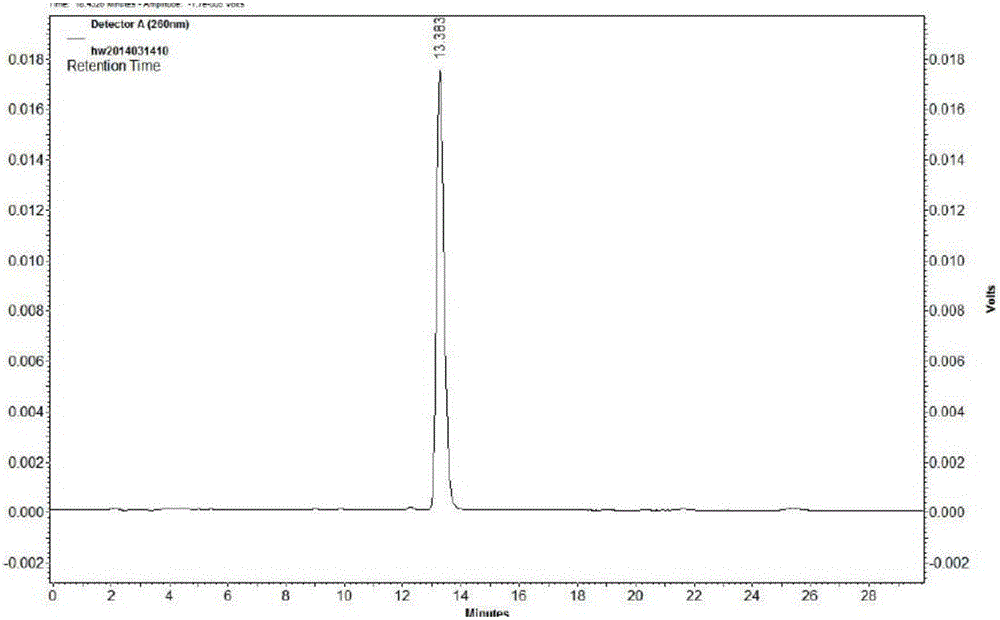

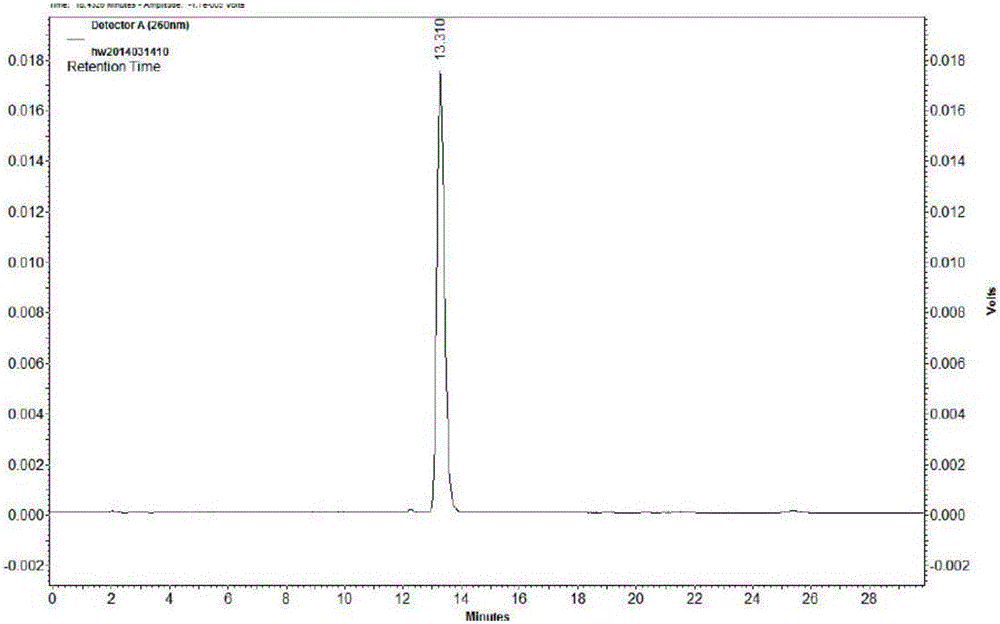

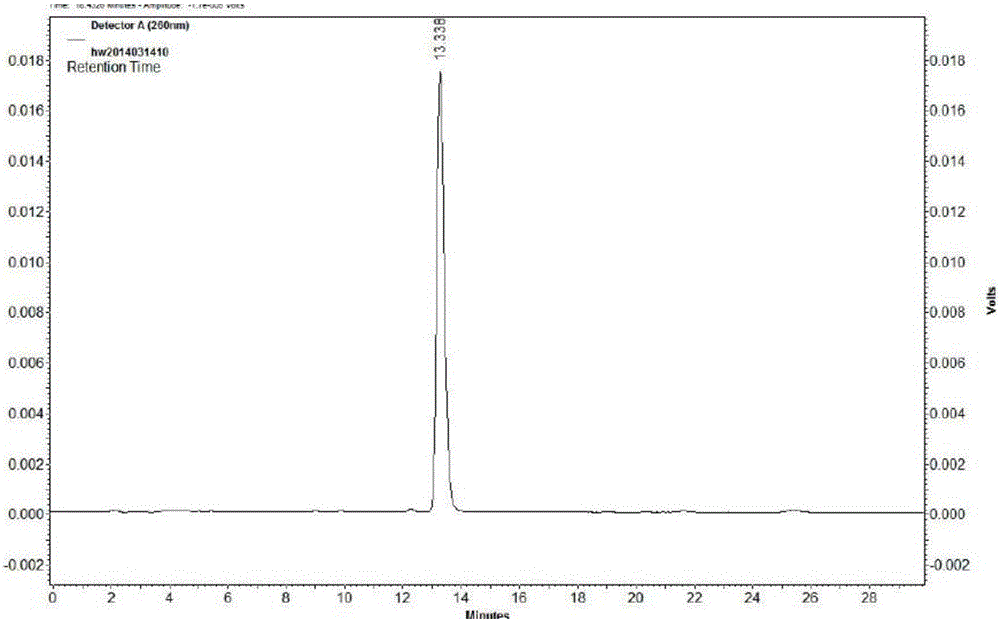

Image

Examples

Embodiment 1

[0025] S1. Material selection: select dried Aconitum tuber in western Yunnan, crush it to 50-100 mesh, and set aside;

[0026] S2. Extraction: soak the root tubers of Aconitum aconitum obtained in step S1 with 95% ethanol for 18 hours, then use 8 times the amount of ethanol to extract it for 5 times, combine the leachate, concentrate to a paste, and obtain an extract;

[0027] S3. Extraction and separation: dissolve the extract obtained in step S1 with 1.5% hydrochloric acid, filter to obtain an acid solution, adjust its pH to 10 with 25% concentrated ammonia water, then add 1 volume times of ethyl acetate, and vibrate for 30 -45min, stand for separation, take the supernatant, repeat the extraction 3 times, combine the extracts, recover under reduced pressure to a paste, and obtain the crude total alkali;

[0028] S4. Separation and purification by column chromatography: dissolve the crude total alkali obtained in step S2 with chloroform, and adsorb on 2 times the amount of si...

Embodiment 2

[0031] S1. Material selection: select dried Aconitum tuber in western Yunnan, crush it to 50-100 mesh, and set aside;

[0032] S2. Extraction: soak the root tubers of Aconitum aconitum obtained in step S1 with 95% ethanol for 16 hours, then extract it three times with 10 times the amount of ethanol, combine the leachate, concentrate to a paste, and obtain an extract;

[0033] S3. Extraction and separation: dissolve the extract obtained in step S1 with 1.5% hydrochloric acid, filter to obtain an acid solution, adjust its pH to 10 with 25% concentrated ammonia water, then add 2 volume times of ethyl acetate, and vibrate for 30 -45min, stand for separation, take the supernatant, repeat the extraction 4 times, combine the extracts, recover under reduced pressure to a paste, and obtain the crude total alkali;

[0034] S4. Separation and purification by column chromatography: dissolve the crude total alkali obtained in step S2 with chloroform, and adsorb on 1 times the amount of sil...

Embodiment 3

[0037] S1. Material selection: select dried Aconitum tuber in western Yunnan, crush it to 50-100 mesh, and set aside;

[0038] S2. Extraction: Soak the root tubers of Aconitum aconitum obtained in step S1 with 95% ethanol for 820 hours, then use 9 times the amount of ethanol to extract it 4 times, combine the leachate, concentrate to a paste, and obtain an extract;

[0039] S3. Extraction and separation: dissolve the extract obtained in step S1 with 1.5% hydrochloric acid, filter to obtain an acid solution, adjust its pH to 10 with 25% concentrated ammonia water, then add 2 volume times of ethyl acetate, and vibrate for 30 -45min, stand for separation, take the supernatant, repeat the extraction 3 times, combine the extracts, recover under reduced pressure to a paste, and obtain the crude total alkali;

[0040] S4. Separation and purification by column chromatography: dissolve the crude total alkali obtained in step S2 with chloroform, and adsorb on 2 times the amount of silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com