Method for synthesizing polysorbate-80 for injection

A technology of polysorbate and synthesis method, which is applied in the field of synthesis of polysorbate-80 for injection, which can solve problems such as high content of by-products and impurities, poor color of polysorbate 80, and failure to meet the requirements for injection use, and achieve fluidity Good performance, low impurity content, and easy control of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

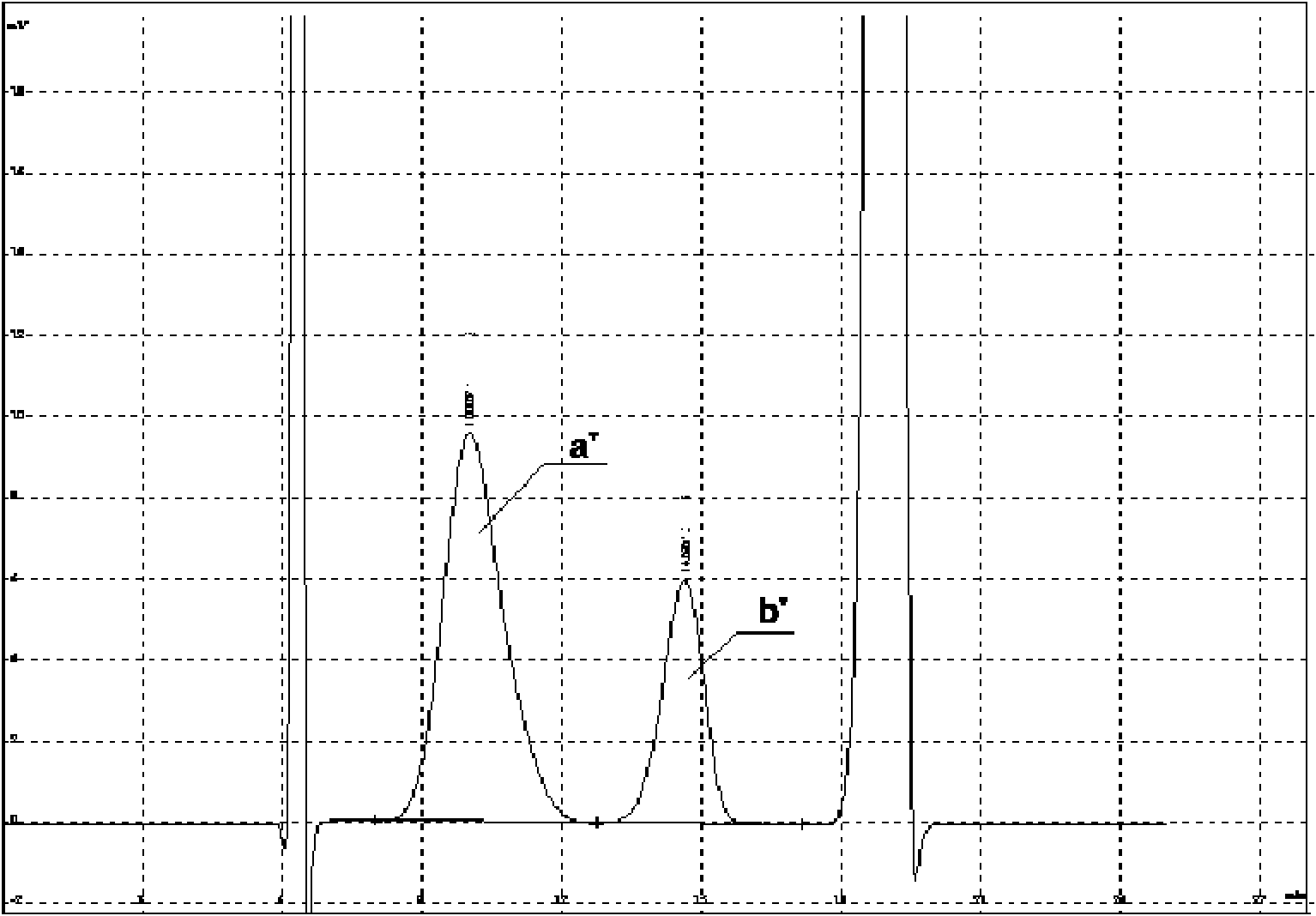

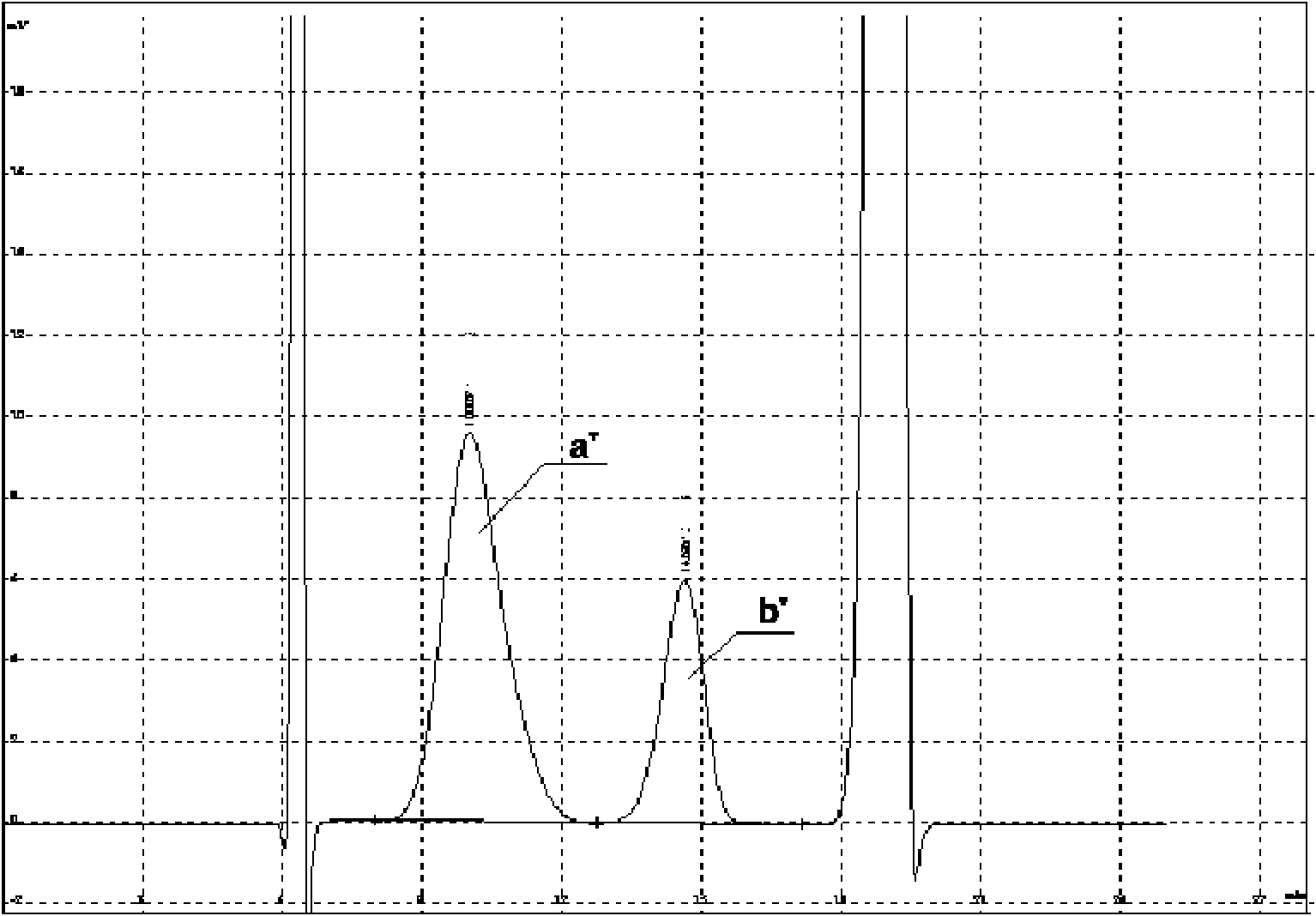

Image

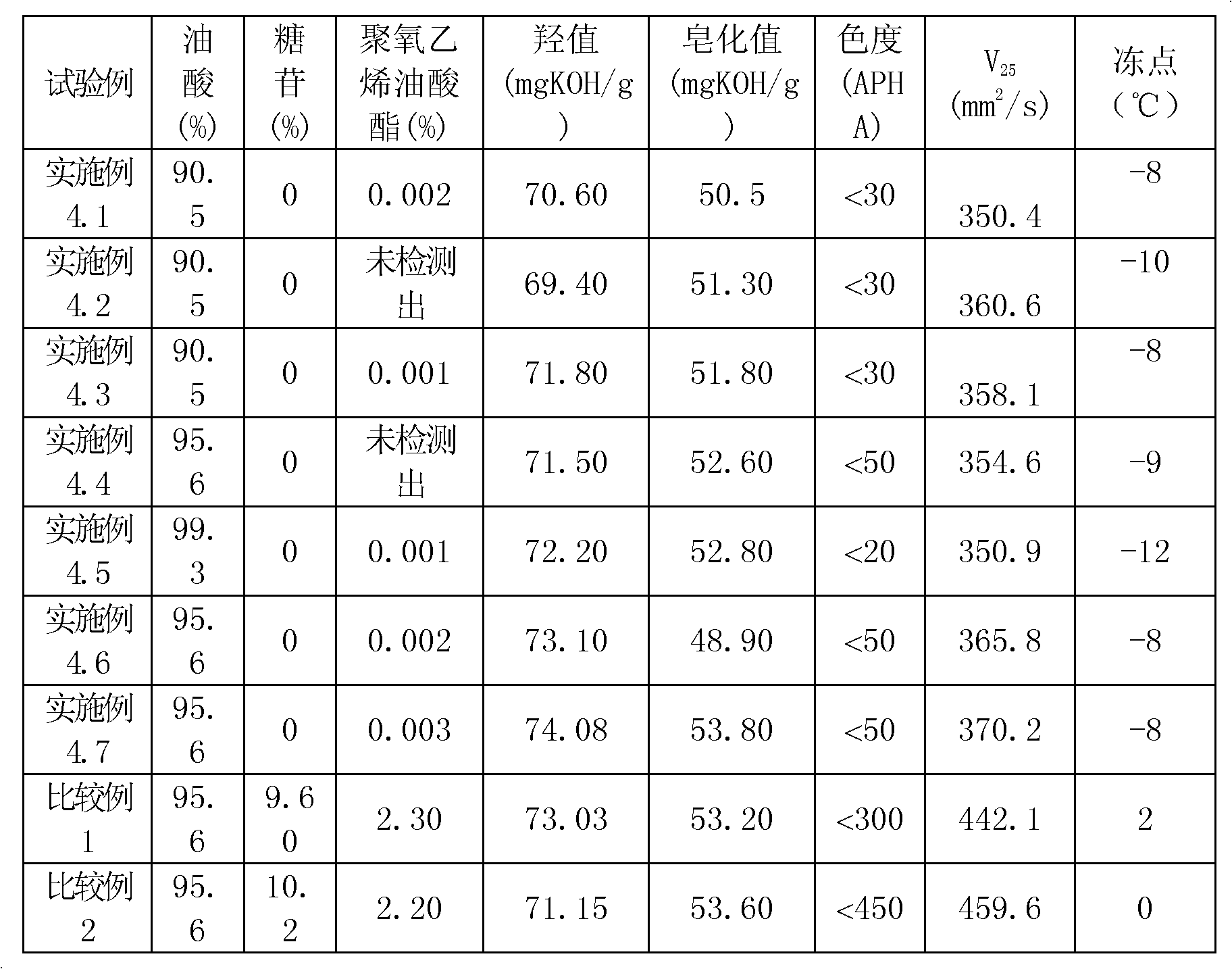

Examples

Embodiment 1

[0056] Embodiment 1-the synthesis of dehydrated sorbitan

[0057] Example 1.1 Add 1400g sorbitol (70%) in a 2000ml three-necked flask, and dehydrate under vacuum at 100-120°C for 3 hours. Cool down to 80°C, add 50g of 20% sulfuric acid aqueous solution, vacuum, dehydration reaction, vacuum degree 750mmHg, dehydration temperature 105-120°C, time 5 hours; neutralize to neutral with 20% sodium hydroxide aqueous solution, add activated carbon for decolorization, Filtration and vacuum drying gave crude sorbitan, which was analyzed by liquid chromatography with a content of 73.74%. 800 g of the obtained 1,4-sorbitol crude product was mixed with methanol to carry out primary crystallization, secondary crystallization and tertiary crystallization, and the content of the tertiary crystallization product was 99.25% (wherein the content of monosorbitol was 97.46%).

[0058] Embodiment 1.2 is substantially the same as embodiment 1.1, but has following changes, replaces 48ml20% sulfuric a...

Embodiment 2 2

[0063] The synthesis of embodiment 2 anhydrosorbitol

Embodiment 2

[0064] Example 2.1 Add 1400g sorbitol (70%) in a 2000ml three-necked flask, and dehydrate under vacuum at 100-120°C for 3 hours. Cool down to 80°C, add 50g of 20% sulfuric acid aqueous solution, vacuum, dehydration reaction, vacuum degree 750mmHg, dehydration temperature 105-120°C, time 5 hours; continue to heat up to 150-170°C dehydration reaction for 6 hours, and oxidize with 20% hydrogen The sodium aqueous solution was neutralized to neutral, and activated carbon was added for decolorization, filtered, and vacuum-dried to obtain a crude product of sorbitol, which was analyzed by liquid chromatography and found to have a content of 63.2%. The prepared dianhydrosorbitol crude product is subjected to vacuum distillation, and the vacuum degree is 759mmHg, and the fraction at 175~185° C. is collected, which is dianhydrosorbitol (isosorbide), and its content is 99.86% (wherein dianhydrosorbide Sorbitol content is 97.58%).

[0065] Embodiment 2.2 is substantially the same as embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com