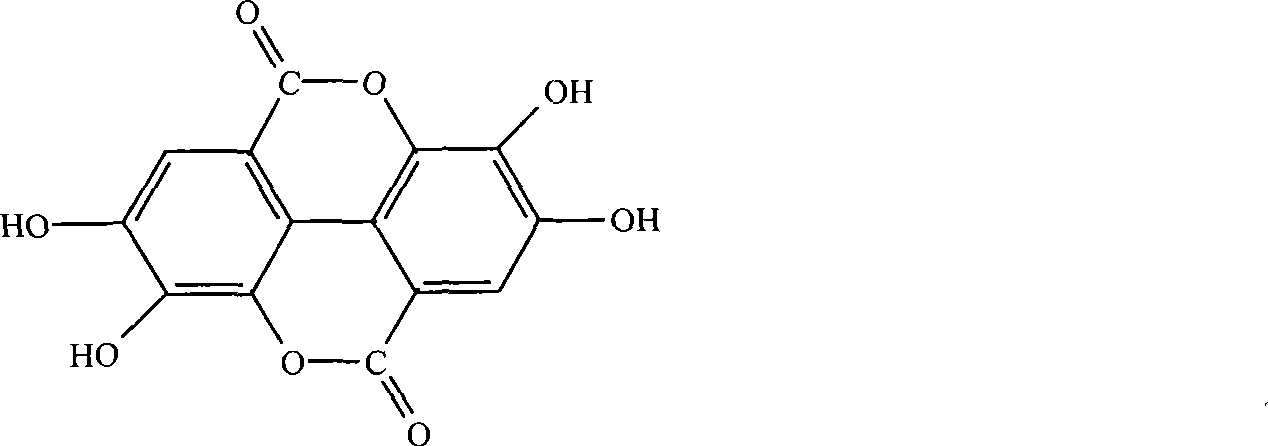

Method for preparing ellagic acid from pomegranate bark by enzyme process

A technology of ellagic acid and pomegranate peel, which is applied in the fields of medicine, chemical industry and food, can solve the problems of cumbersome and complicated preparation process, difficult separation and purification, difficulty in ellagic acid, etc., and achieve simple process, saving consumption and easy treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A Extraction of ellagitannins:

[0026] After crushing 80 kg of dried pomegranate peels, add them to 600 L of 40% ethanol aqueous solution, conduct ultrasonic treatment for 25 minutes under the action of ultrasonic waves with a power of 80W, take out and collect the filtrate, and repeat the above ultrasonic treatment for the remaining residue Second, the obtained ethanol aqueous solution of ellagitannin was concentrated to recover ethanol to obtain 240 L of concentrated ellagitannin solution.

[0027] Fermentation culture of B tannin:

[0028] The composition and content of the fermented seed medium are: NaNO 3 2g / l, K 2 HPO 4 1g / l, MgSO 4 ·7H 2 O 0.6g / l, KCl 0.6g / l, FeSO 4 0.01g / l, sucrose 30g / l, and the rest is water. After sterilization, add Aspergillus niger 3.316 immediately, at 30 ℃, 165rpm Shaker culture 24 hours, move in the enzyme production medium with 5% inoculum size, the composition and mass content of enzyme production medium: ellagitation Tanni...

Embodiment 2

[0033] A Extraction of ellagitannins:

[0034]After pulverizing 80 kg of dried pomegranate peels, add them to 600 L of ethanol aqueous solution with a volume concentration of 60%, and conduct ultrasonic treatment for 30 minutes under the action of ultrasonic waves with a power of 100 W, take out and collect the filtrate, and repeat the above ultrasonic treatment twice for the remaining residue , to obtain an ethanol aqueous solution of ellagitannin, and after concentration and recovery of ethanol, 200 L of ellagitannin concentrated solution was obtained.

[0035] Fermentation culture of B tannin:

[0036] The composition and content of the fermented seed culture medium are: NaNO 3 1.5g / l, K 2 HPO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, KCl 0.5g / l, FeSO 4 0.01g / l, sucrose 25g / l, and the rest is water. After sterilization, add Aspergillus niger 3.316 immediately, at 28 ℃, shaker culture at 165rpm for 22 hours, move to the enzyme-producing medium with 5% inoculum, the composit...

Embodiment 3

[0042] A Extraction of ellagitannins:

[0043] After crushing 80 kg of dried pomegranate peels, add them to 600 L of ethanol aqueous solution with a volume concentration of 50%, and perform ultrasonic treatment for 40 minutes under the action of ultrasonic waves with a power of 90W, take out and collect the filtrate, and repeat the above ultrasonic treatment once for the remaining residue , After the obtained ethanol aqueous solution of tannic acid was concentrated and recovered ethanol, 200 L of ellagitannin concentrate was obtained.

[0044] Fermentation culture of B tannin:

[0045] The composition and content of the fermented seed medium are: NaNO 3 2.5g / l, K 2 HPO 4 1.5g / l, MgSO 4 ·7H 2 O 0.8g / l, KCL 0.8g / l, FeSO 4 0.015g / l, 35g / l sucrose, and the rest is water. After sterilizing, add Aspergillus niger 3.316 immediately, at 25 DEG C, 165rpm down shaker culture 24 hours, move in the enzyme production medium with 5% inoculum size, the composition and content of enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com