Method for recycling silver nanowire waste

A nano-silver wire and waste technology, which is applied in the field of recycling nano-silver wire waste, can solve the problems of unsatisfactory processing effect and affecting the purity of nano-silver wire, and achieve the effect of increasing the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

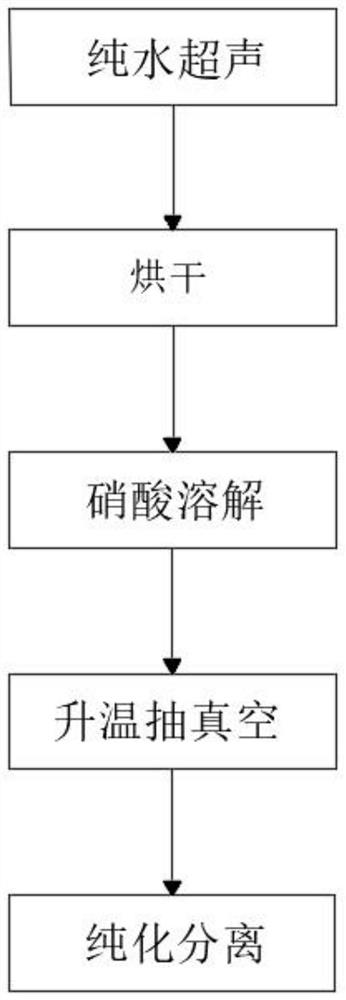

[0024] see figure 1 , the embodiment provided by the present invention: a kind of method for reclaiming nano-silver wire waste, its construction process has pure water ultrasonic → drying → nitric acid dissolution → heating and vacuumizing → purification and separation, it is characterized in that: comprises the following five steps:

[0025] Step 1: import the corresponding proportion of nano-silver wire and pure water into the glass container, put the collected nano-silver wire waste into the glass container and use ultrasonic equipment to ultrasonicate the nano-silver wire waste, pure water can remove the For particles with a particle size below 20nm, especially below 10nm, it is necessary to prevent debris or dust from falling into the glass container during the ultrasonic cleaning process, which will affect the cleaning effect;

[0026] Step 2: using the drying equipment to dry the nano-silver wire waste to make it reach the dryness of the subsequent treatment. When dryin...

Embodiment 2

[0038] 1. The collection process of nano silver wire waste:

[0039]Use recycling equipment to collect nano-silver wire waste into a large container for storage. The storage container needs to be high-strength and anti-corrosion to prevent the container from being damaged by external force during transportation, causing the nano-silver wire waste to scatter. When transporting the nano-silver wire waste to the processing location Unloading, cutting and separating the protective layer on the outside of the nano-silver wire, obtaining the nano-silver wire waste, and using a washing device to wash the surface of the nano-silver wire waste to realize the collection of the nano-silver wire waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com