Preparation method of silver electrolyte

An electrolyte and gold liquid technology, applied in the field of comprehensive utilization of non-ferrous metallurgical resources, can solve the problems of high reagent consumption and operation intensity, reduce the direct yield of silver electrolysis process, etc., and achieve high environmental protection benefits, low cost, simple and easy operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

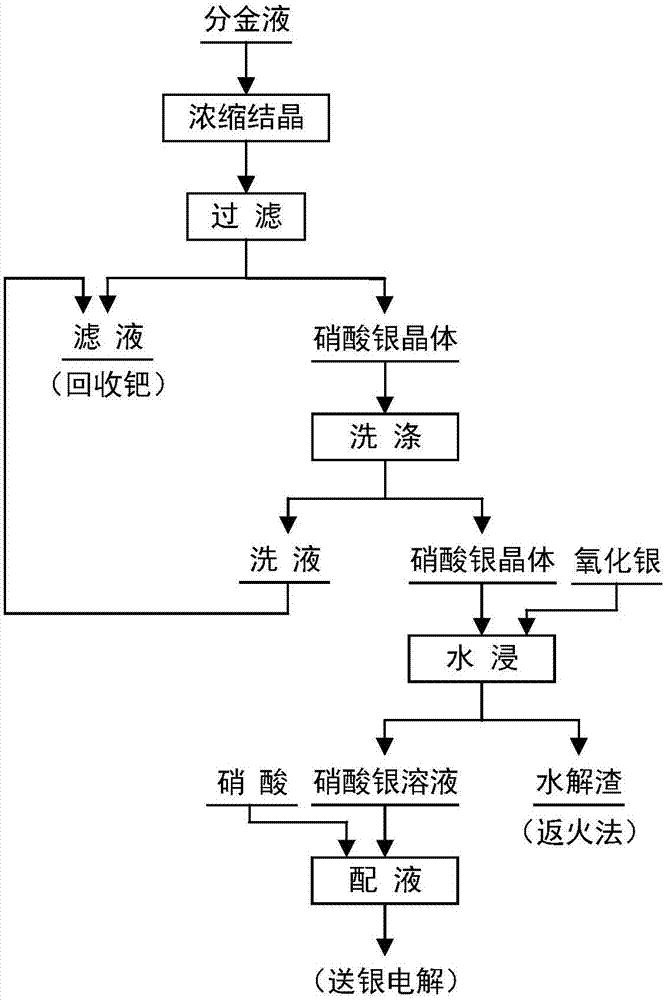

[0029] see figure 1 , which is a process flow diagram of a method for preparing a silver electrolyte according to an embodiment of the present invention.

[0030] A kind of comprehensive utilization method of silver anode cloth bag washing water comprises the following steps:

[0031] (1) Concentrated crystallization

[0032] Pump 500L gold separation liquid into the concentrated crystallizer. The composition of the gold separation liquid is as follows: Ag 280g / L, Cu 4.5g / L, Pd 1.10g / L, Au 0.012g / L, Pb 0.26g / L, Bi 2.6g / L, control the temperature at 100°C, concentrate until the volume is 1 / 2 (that is, 250L), release the material, and carry out solid-liquid separation (filtering) after it cools and crystallizes naturally to obtain filtrate and silver nitrate crystals. The filtrate is sent to the palladium recovery process.

[0033] (2) Crystal washing

[0034] The obtained silver nitrate crystals are dried and placed in a cylindrical filter device, controlled at a negative p...

Embodiment 2

[0041] see figure 1 , which is a process flow diagram of a method for preparing a silver electrolyte according to an embodiment of the present invention.

[0042] A kind of comprehensive utilization method of silver anode cloth bag washing water comprises the following steps:

[0043] (1) Concentrated crystallization

[0044] Pump 500L gold separation liquid into the concentrated crystallizer. The composition of the gold separation liquid is as follows: Ag 320g / L, Cu 5.2g / L, Pd 1.20g / L, Au 0.015g / L, Pb 0.32g / L, Bi 3.6g / L. , control the temperature at 110°C, and concentrate to 1 / 3 of the volume (that is, 167L), release the material, and perform solid-liquid separation (filtering) after natural cooling and crystallization to obtain the filtrate and silver nitrate crystals, and the obtained filtrate is sent to palladium for recovery process.

[0045] (2) Crystal washing

[0046] The obtained silver nitrate crystals are dried and put into the cylindrical filter equipment, and t...

Embodiment 3

[0053] see figure 1 , which is a process flow diagram of a method for preparing a silver electrolyte according to an embodiment of the present invention.

[0054] A kind of comprehensive utilization method of silver anode cloth bag washing water comprises the following steps:

[0055] (1) Concentrated crystallization

[0056] Pump 500L gold separation liquid into the concentrated crystallizer. The composition of the gold separation liquid is as follows: Ag 300g / L, Cu 5.0g / L, Pd 1.15g / L, Au 0.014g / L, Pb 0.29g / L, Bi 3.1g / L, control the temperature at 120°C, concentrate to 1 / 3 of the volume (being 167L), release the material, and carry out solid-liquid separation (filtering) after it cools and crystallizes naturally to obtain the filtrate and silver nitrate crystals, the obtained The filtrate is sent to the palladium recovery process.

[0057] (2) Crystal washing

[0058] The obtained silver nitrate crystals are dried and placed in a cylindrical filter device, controlled at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com