Method and device for removing volatile impurities in aqueous solution and preparing crystal product through air circulation gas stripping concentration

A technology of air circulation and high-concentration aqueous solution, which is applied in the direction of solution crystallization, general layout of crystallization devices, evaporation, separation and crystallization, etc., and can solve the problems of limiting the industrial application of air lift and crystallization technology, large transfer resistance in the liquid phase, and gas-liquid interface. Weak driving force for mass transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

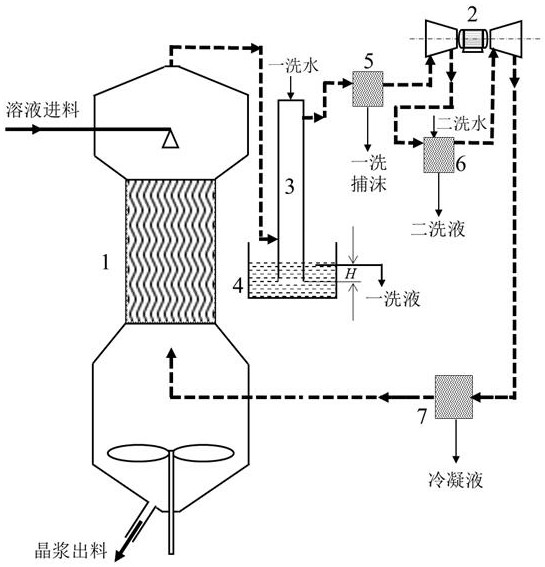

[0010] Example 1: Silver nitrate (AgNO 3 ) aqueous solution by gas stripping and concentrating to prepare 400kg / h of silver nitrate crystals.

[0011] as attached figure 1 As shown, 800 kg / h of silver nitrate aqueous solution with a temperature of 100 °C and a mass concentration of 82.34% is used as a raw material, and a 1000 kg / h air circulation is used to extract and concentrate the preparation amount of 400 kg / h of silver nitrate crystals. The cross-section of the corrugated plate array of the gas stripping and concentrating crystallizer 1 is an equilateral rectangle with a side length of 0.2m. The array is composed of 30 upright triangular corrugated plates with a width of 0.2m and a height of 0.5m uniformly arranged in the same direction. The spacing between the plates is 6.9mm. The distance is 30mm, and the corrugation inclination angle is 30°. The silver nitrate aqueous solution raw material is evenly distributed on the cross-section of the corrugated plate array by ...

Embodiment 2

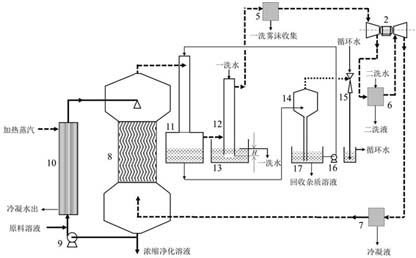

[0012] Embodiment 2: to 50000kg / h concentration 55% (H 3 PO 4 ) of the wet-process phosphoric acid solution is stripped and concentrated for defluorination to increase its concentration to 70% (H 3 PO 4 ) above, fluorine does not exceed 0.05% (F).

[0013] as attached figure 2 As shown, the raw material wet-process phosphoric acid solution is 50000kg / h, the concentration is 55% (H 3 PO 4 ), containing 2% fluorine (F), temperature 40°C; use 22000kg / h air circulation to extract and concentrate defluorination, and increase its concentration to 70% (H 3 PO 4 ), the fluorine content is reduced to 0.05% (F). The cross-section of the corrugated plate array of the gas stripping and concentrating purifier 8 is an equilateral rectangle with a side length of 1.1m. The array is composed of 220 upright triangular corrugated plates with a width of 1.1m and a height of 2.8m evenly arranged in the same direction. The spacing between the plates is 5mm, and the corrugation pitch 30mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com